Stainless Steel Sheet/Plate 310 with Better Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 310 with Better Temperature Resistance

Description of Stainless Steel Sheet/Plate 310 with Better Temperature Resistance:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel Sheet/Plate 310 with Better Temperature Resistance:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Application of Stainless Steel Sheet/Plate 310 with Better Temperature Resistance:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many application

s.There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates,

bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipme

nt Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion re

sistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steam

cleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel Sheet/Plate 310 with Better Temperature Resistance:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 310 with Better Temperature Resistance:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

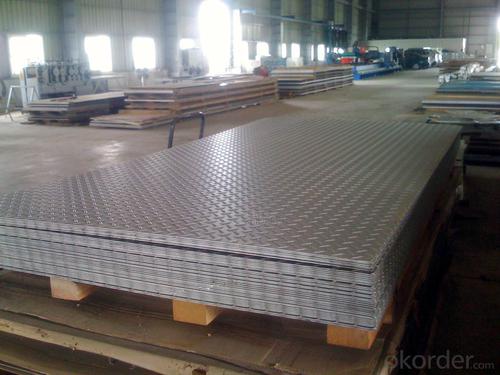

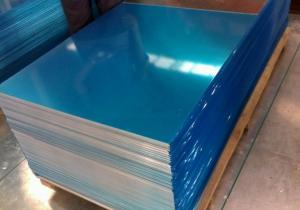

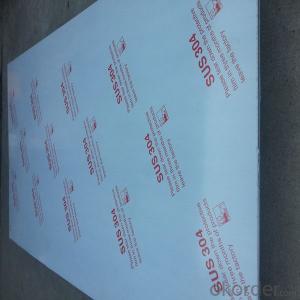

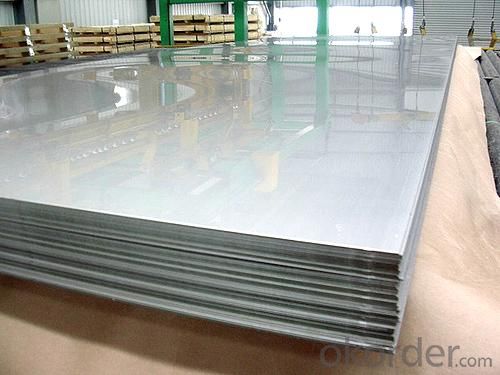

Images of Stainless Steel Sheet/Plate 310 with Better Temperature Resistance:

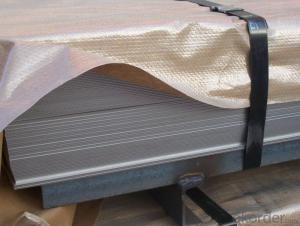

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 310 with Better Temperature Resistance:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the hardness of stainless steel sheets?

- The hardness of stainless steel sheets can vary depending on the specific grade and manufacturing process. Generally, stainless steel sheets are known for their high hardness and strength. The most common grades used in industrial applications, such as 304 and 316, have a hardness range of 70-90 HRB (Rockwell hardness B scale) or 150-200 HV (Vickers hardness). However, there are also specialized stainless steel alloys that can have even higher hardness values, such as precipitation-hardened grades like 17-4 PH, which can reach hardness levels of 30-40 HRC (Rockwell hardness C scale). To determine the exact hardness of a specific stainless steel sheet, it is necessary to consult the manufacturer's specifications or perform hardness testing using appropriate methods and equipment.

- Q: What are the specifications of stainless steel plates? Are they the same width?

- Generally look at the thickness of 0.3-3.0mm, width of 1000/1219/1500. Thickness of 3 or more, with 1240/1250/1500/1800/2000 width. It can be cut as required.... So the purchase is still more flexible.

- Q: Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are commonly used in the manufacturing of medical equipment or devices due to their excellent corrosion resistance, durability, ease of cleaning, and ability to withstand sterilization processes.

- Q: What are the applications of stainless steel sheets in the construction industry?

- Stainless steel sheets have various applications in the construction industry due to their unique properties and characteristics. Here are some of the key applications of stainless steel sheets in construction: 1. Roofing and Cladding: Stainless steel sheets are widely used for roofing and cladding in commercial and residential buildings. They provide excellent resistance against corrosion, harsh weather conditions, and fire, making them a durable and long-lasting option. 2. Facades and Curtain Walls: Stainless steel sheets are frequently used in the construction of facades and curtain walls. Their attractive appearance, high strength, and resistance to staining and fading make them a popular choice for creating visually appealing and low-maintenance building exteriors. 3. Structural Components: Stainless steel sheets find applications in the construction of various structural components, such as beams, columns, and support systems. Their high strength-to-weight ratio, resistance to deformation, and durability make them ideal for ensuring the structural integrity of buildings. 4. Handrails and Balustrades: Stainless steel sheets are commonly used for designing handrails, balustrades, and guardrails in both indoor and outdoor settings. They offer excellent resistance to corrosion, impact, and wear, while their sleek and modern appearance adds an aesthetic touch to the overall design. 5. Kitchen and Bathroom Fixtures: Stainless steel sheets are extensively used for fabricating kitchen and bathroom fixtures, such as sinks, countertops, backsplashes, and shower enclosures. Their resistance to moisture, heat, and stains, along with their easy maintenance, make them a practical and hygienic choice. 6. Interior Design Elements: Stainless steel sheets are utilized in the construction of various interior design elements, including wall panels, ceiling panels, elevator interiors, and decorative screens. Their smooth and reflective surface, combined with their versatility in terms of finishes and patterns, allows for creating visually appealing and modern interiors. 7. HVAC Systems: Stainless steel sheets are often used in HVAC (heating, ventilation, and air conditioning) systems due to their high-temperature resistance, corrosion resistance, and ease of cleaning. They are commonly employed in ductwork, air handling units, and exhaust systems to ensure efficient and durable performance. Overall, stainless steel sheets offer numerous advantages in the construction industry, including durability, corrosion resistance, low maintenance requirements, and aesthetic appeal. These qualities make them a preferred choice for a wide range of applications, contributing to the overall quality and longevity of construction projects.

- Q: Can stainless steel sheets be used for swimming pool construction?

- Yes, stainless steel sheets can be used for swimming pool construction. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the harsh conditions of a swimming pool environment. It is commonly used for constructing pool walls, floors, and other structural components.

- Q: Can stainless steel sheets be used for marine propellers?

- Yes, stainless steel sheets can be used for marine propellers. Stainless steel is known for its corrosion resistance and durability, making it suitable for marine applications. Its strength and resistance to saltwater corrosion make it a popular choice for manufacturing marine propellers.

- Q: What is the strain hardening exponent of stainless steel sheets?

- The strain hardening exponent of stainless steel sheets refers to the material's ability to increase its strength and hardness as it undergoes plastic deformation or strain. It is a measure of how the material's stress-strain curve changes with increasing deformation. Stainless steel sheets typically have a strain hardening exponent ranging between 0.2 and 0.4. This value indicates that the material exhibits a moderate increase in strength and hardness as it is subjected to plastic deformation. The higher the strain hardening exponent, the greater the material's ability to resist deformation and retain its shape under external forces. The strain hardening exponent is an important parameter in engineering applications as it affects the material's formability, ductility, and resistance to deformation. Higher values of the strain hardening exponent indicate a more work-hardening material, which is desirable in many industrial processes such as sheet metal forming or cold working. However, excessively high strain hardening exponents can lead to issues like cracking or material failure. It is important to note that the strain hardening exponent can vary depending on the specific grade and composition of the stainless steel alloy. Different stainless steel alloys may exhibit different strain hardening behaviors, so it is crucial to consider the specific material properties and specifications when determining the strain hardening exponent for a particular stainless steel sheet.

- Q: Can stainless steel sheets be formed into complex shapes?

- Complex shapes can indeed be formed from stainless steel sheets. Stainless steel is renowned for its exceptional formability and versatility, establishing it as a highly utilized material across numerous industries. It can be readily manipulated through various fabrication techniques like bending, rolling, stamping, and deep drawing, facilitating the creation of intricate shapes with utmost precision and accuracy. Furthermore, stainless steel possesses remarkable ductility, enabling it to endure substantial deformation while retaining its mechanical properties and structural integrity. Consequently, it is frequently favored for applications necessitating intricate and tailored designs, including architectural structures, automotive components, kitchen appliances, and medical devices.

- Q: Can stainless steel sheets be used for escalator steps?

- Certainly, escalator steps can be made from stainless steel sheets. The reason stainless steel is highly favored for escalator steps is its exceptional durability, strength, and resistance to corrosion. It can endure the ceaseless foot traffic, hefty loads, and daily wear and tear that escalator steps face. Moreover, stainless steel possesses a sleek and contemporary look that contributes to the overall aesthetic charm of escalators. Consequently, stainless steel sheets emerge as a dependable and pragmatic option for escalator steps in a range of commercial and public environments.

- Q: Are stainless steel sheets suitable for outdoor railings?

- Yes, stainless steel sheets are suitable for outdoor railings. Stainless steel is highly resistant to corrosion, making it a durable and long-lasting material for outdoor applications. It can withstand exposure to various weather conditions, including rain, snow, and sunlight, without rusting or deteriorating. Stainless steel also offers a sleek and modern appearance, making it a popular choice for outdoor railings.

Send your message to us

Stainless Steel Sheet/Plate 310 with Better Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords