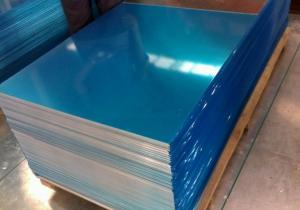

310S cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of 310S STAINLESS STEEL SHEET.

STAINLESS STEEL SHEET IS ONE POPULAR PRODUCTS IN CHINA MARKET, IT HAVE SEVERAL DIFFERENT APPLICATIONS, SUCH AS, CONSTRUCTION, BUILDING, DECORATION, ETC.

THE GRADE ALSO INCLUDE: 200 SERIES, 300 SERIES, 400 SERIES, ETC.

Mainly applied in the industry of furniture, sports equipment, compressed containers, shipbuilding, railway and the automotive.

2、Main Features of the 304 STAINLES STEEL SHEET.

High intensity

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance

Wide applicability.

Length per spool only for reference

Spool Size Weight Specifications

D300mm 6Kg~7Kg 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.6mm

5、FAQ of 310S STAINLESS STEEL SHEET.

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do I prevent rusting on stainless steel sheets?

- To prevent rusting on stainless steel sheets, it is important to keep them clean and dry. Regularly clean the sheets with mild soap and water, and avoid using abrasive cleaners or scrubbing tools that can damage the protective layer. Additionally, ensure the sheets are completely dry after cleaning to prevent moisture accumulation. Applying a coat of mineral oil or a stainless steel cleaner can also help create a barrier against rust.

- Q: Can stainless steel sheets be used for backsplashes?

- Stainless steel sheets are indeed suitable for use as backsplashes. The reason why stainless steel is a popular option for this purpose is because it is durable, resistant to both heat and moisture, and requires minimal maintenance. Given that kitchen areas often experience high levels of heat and moisture, stainless steel is capable of withstanding these conditions, making it an ideal material for safeguarding walls behind stovetops and sinks. Moreover, stainless steel backsplashes can enhance the kitchen's appearance by providing a modern and sleek touch that complements various design styles. Additionally, cleaning stainless steel backsplashes is a breeze, as they can easily be wiped down using a damp cloth or cleaned with mild soap and water. All in all, stainless steel sheets are a practical and visually appealing choice for both residential and commercial backsplashes.

- Q: Are stainless steel sheets resistant to abrasion?

- Yes, stainless steel sheets are highly resistant to abrasion.

- Q: Can stainless steel sheets be used for air conditioning systems?

- Yes, stainless steel sheets can be used for air conditioning systems. Stainless steel is a durable and corrosion-resistant material, making it suitable for use in air conditioning systems where it may be exposed to moisture and varying temperatures. Additionally, stainless steel's high strength-to-weight ratio makes it ideal for constructing components such as ductwork, evaporator coils, and heat exchangers in air conditioning systems.

- Q: Can stainless steel sheets be used for water treatment equipment?

- Indeed, water treatment equipment can indeed utilize stainless steel sheets. The exceptional resistance of stainless steel to both corrosion and oxidation renders it an optimal substance for water treatment purposes. In fact, it is frequently employed for the construction of tanks, pipes, valves, and other essential components within water treatment systems. Due to its durability and hygienic attributes, stainless steel proves itself capable of handling diverse forms of water, ranging from potable water to wastewater and industrial process water. Furthermore, stainless steel's effortless cleaning and maintenance procedures guarantee the longevity and effectiveness of water treatment equipment.

- Q: Are stainless steel sheets suitable for outdoor sculptures or decorative pieces?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or decorative pieces. Stainless steel is known for its durability, resistance to corrosion, and ability to withstand harsh weather conditions, making it an ideal choice for outdoor applications. Additionally, its sleek and polished appearance adds a touch of elegance and modernity to any outdoor space.

- Q: What are the different types of stainless steel sheet edges available?

- Different options are available for stainless steel sheet edges, each with its own unique advantages and characteristics. 1. The mill edge is the standard finish produced during manufacturing. It features a straight, sharp edge without any additional treatment. Mill edge stainless steel sheets are commonly used in industrial applications where aesthetics are not a priority. 2. Slit edge sheets are created by cutting the sheet along its length, resulting in a slightly rounded edge. This type of edge is often used in applications where safety is a concern, as it reduces the risk of sharp edges causing injury. 3. Sheared edge sheets are created by cutting the sheet along its width using shearing blades. This process produces a clean, straight edge without any additional finishing. Sheared edge sheets are often used in applications that require precise dimensions. 4. Deburred edge sheets have undergone a process to remove any sharp or rough edges, resulting in a smooth and safe edge finish. Deburring is typically done using abrasive materials or specialized machinery. These sheets are commonly used in applications that prioritize safety and aesthetic appearance. 5. Rolled edge sheets have a curved or rounded edge, created by rolling the sheet during manufacturing. This edge type is commonly used in applications where a smoother and more finished appearance is desired. Rolled edge sheets are also easier to handle and less likely to cause injury during installation. Ultimately, the choice of stainless steel sheet edge depends on the specific requirements of the application, considering factors such as safety concerns, aesthetic preferences, and dimensional accuracy.

- Q: What are the different types of perforations available for stainless steel sheets?

- There are several different types of perforations available for stainless steel sheets, each serving a specific purpose and offering unique characteristics. Here are some of the most common types: 1. Round Perforations: These are the most basic and widely used type of perforations. They consist of evenly spaced round holes punched through the stainless steel sheet. Round perforations offer good airflow and visibility while providing adequate strength and durability. 2. Square Perforations: Similar to round perforations, square perforations feature evenly spaced square holes instead of round ones. Square perforations are often preferred when a more geometric and modern aesthetic is desired, as they can create a visually appealing pattern. 3. Slotted Perforations: Slotted perforations are characterized by elongated, rectangular holes that are punched through the stainless steel sheet. This type of perforation allows for better drainage and airflow, making it suitable for applications such as grilles, screens, and filters. 4. Hexagonal Perforations: Hexagonal perforations feature hexagon-shaped holes that are punched through the stainless steel sheet. This type of perforation offers an interesting visual pattern and can provide better strength and rigidity compared to round or square perforations. 5. Decorative Perforations: These perforations are specifically designed to enhance the aesthetic appeal of stainless steel sheets. They can come in various shapes, sizes, and patterns, including floral, geometric, or custom designs. Decorative perforations are often used in architectural applications, interior design, and decorative panels. 6. Micro Perforations: Micro perforations are extremely small holes that are closely spaced in the stainless steel sheet. They are commonly used in applications where a high level of precision and fine filtering is required, such as speaker grilles, ventilation systems, or sieves. It's important to note that the availability of specific perforation types may vary depending on the supplier or manufacturer. Additionally, some suppliers may offer custom perforation options to meet unique requirements or design preferences.

- Q: Are stainless steel sheets suitable for solar panel frames?

- Yes, stainless steel sheets are suitable for solar panel frames. Stainless steel is known for its durability, corrosion resistance, and ability to withstand extreme weather conditions, making it a reliable material for supporting and protecting solar panels. Its strength-to-weight ratio also makes it ideal for constructing lightweight yet sturdy frames that can withstand the rigors of outdoor installations.

- Q: Are stainless steel sheets suitable for aerospace applications?

- Stainless steel sheets are well-suited for aerospace applications. This material, known for its versatility and durability, possesses outstanding strength-to-weight ratio, corrosion resistance, and high-temperature resistance. Consequently, it is highly valued within the aerospace industry due to its ability to endure extreme conditions while maintaining structural integrity. Its wide utilization in aircraft structures, engine components, and fuel systems is a testament to its reliability. Furthermore, stainless steel sheets are easily molded, welded, and fabricated, allowing for tailored engineering and precise customization in aerospace applications. Moreover, their resistance to fatigue and erosion ensures their dependability in components that experience constant stress and severe environments. In summary, stainless steel sheets possess the essential qualities necessary to meet the demanding requirements of the aerospace industry, making them an appropriate choice for a variety of applications.

Send your message to us

310S cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords