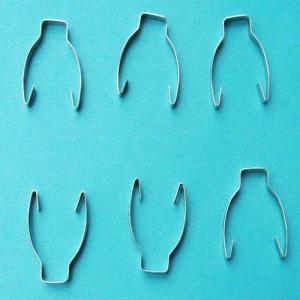

High Quality 100% Ductile Iron Casting Parts

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Ductile Iron Casting Parts

| Brand Name | MOULDDD |

| Place of Origin | Liaoning, China( Mainland) |

| Material | Gray & Ductile Iron |

| Finish | Natural Color |

| Technology | Silica Sol,compound die for the shell process,casting technology of watglass in our Precision casting workshop: we also have resin sand casting process water glass process in our sand workshop. |

| OEM Service | Acceptable |

Specification of Ductile Iron Casting Parts

| Casting Process | Clay sand casting, furan resin sand casting, shell mold casting; Water-glass sand casting, water-glass investment casting, lost-wax investment casting; Die casting, sand casting, lost-wax casting. |

Application | Machinery part,/Casting/Tractor/Pump Valve/Impeller/Electrical equipment/Auto parts/ Farm machinery/Railway equipment/Mining machinery/Engineering machinery/ Petroleum machinery etc. |

| Equipment | CMM. CNC X-Ray |

| Dimensions | According to customer request |

| Certificate | ISO9001:2000, Mill Certificate |

| Inspection | Mechinical Property Inspection |

Usage&Application

Machinery part,/Casting/Tractor/Pump Valve/Impeller/Electrical equipment/Auto parts/

Farm machinery/Railway equipment/Mining machinery/Engineering machinery/

Petroleum machinery etc.

Packing&Delivery

Packing Details: inner cartons and outer wooden box.

Delivery Details: 30 days after order confimationa and deposite.

- Q: What is the flow of mold design?

- When I do die design to get the products, first look at the size of the product, product requirements (materials, points, etc.), and then look at the structure of the product, for example on what needs to be done to open mold, which [dead (slider), inclined top, collision and cutter teeth, the most common core according to the characteristics of the products], there are some products, only a parting direction, some products will have a variety of parting direction, this refers to the type of die surface. The same direction of the mold parting surface can also be produced according to different products go to different places, parting the ingenious will reduce the mold cost and prolongs the service life of the mould, really want to know the process to mold factories to see inside,

- Q: How to enter the mold industry?

- It's good to study for six months under the master gate

- Q: What are the types of moulds? What is the main job of mold design? Does mold design need to be opened, such as machining centers, CNC machine tools, or design before a single computer?

- The rapid development of mold manufacturing technology has become an important part of modern manufacturing technology. If the mold CAD/CAM technology, mold laser rapid prototyping technology, precision die forming technology, ultra precision machining technology of mold, mold in the design using finite element method, boundary element method, flow dynamic simulation technology of cooling and heat transfer process, CIMS technology has been in the development of mold, mold DNM technology and NC technology, covering almost all modern manufacturing technology. Modern die manufacturing technology is developing towards accelerating information drive, improving manufacturing flexibility, agile manufacturing and systematic integration. A: the third generation of high speed milling, molding technology of high speed milling not only has high processing speed and good machining accuracy and surface quality, and compared with the traditional machining with low temperature (workpiece only increases 3 DEG C), small thermal deformation, which is suitable for the temperature and thermal deformation of sensitive materials (such as magnesium alloy etc.) processing; also because the cutting force is small, suitable for machining thin and poor rigidity; reasonable selection of cutting tools and cutting parameters, can realize the hard material (HRC60) has a series of advantages, such as processing. Therefore, the high-speed milling technology is still a hot topic at present. It has developed towards higher agility, intelligence and integration, becoming the third generation of mould making technology. Two, EDM milling and "green" products from foreign electric processing machine, regardless of the performance, process indicators, intelligent and automation have reached a very high level, the new trend of overseas is EDMMILL Technology (electric spark...

- Q: I want to teach myself the die design (plastic mould). Please tell me which books I need. What's the title of the book? I'd like to have more details. Thank you

- This book can be used as the material forming and Control Engineering (mold design and manufacturing), students majoring in polymer materials and engineering and other materials, but also for the relevant technical personnel engaged in plastic molding process and mold design reference.

- Q: please some Mold professionals enter!

- You can learn the software. Software is not many, but in essence. Because you work, you usually use 1~2 software, and you don't need to do everything.You are recommended to learn CAD and 3dsmaxIf you encourage too much, you won't say anything else. The design of the mold is not very easy, but it depends on your confidence. Looking for a job or personal preference?.

- Q: What's the future of the mold?

- China's mold manufacturing industry is very developed. I think learning mold manufacturing English should be. Because a lot of mold professional use of software are related to english. In the national economy is used in the mold industry a lot, often contact die stamping, casting, forging, injection molding, glass, ceramic...... so you should have a professional molding of these general understanding, understanding of various professional technology and die structure characteristics, at the same time should delve into a two forming process. To achieve this level of professional expert. In the multi study theory, we should observe more and practice more. What kind of mold work no matter, space imagination talent and training are indispensable, if this does not pass, don't step into the mold industry as early as possible. Now no matter what cannot do without mold design, programming, CNC machining, and each of these links are required computer knowledge, so the modern mold professional computer knowledge is essential to design, engineering drawing (2D) and three-dimensional modeling software, such as OutoCAD, pro/E, UG, SolidWorks and so on, also have programming the basic principle of many NC programming software, should be familiar with CNC machine and accumulated operating experience. The above is mainly the process of modern processing. In fact, all kinds of mold manufacturing should also know all kinds of mold material knowledge ---- selection and processing. Understand the machining process and process of common machine tools. In short, no matter what kind of mold to be engaged in, it should be from design to material to the entire process of processing should be clear. The potential of the mold industry is very large, the key is that you should be one to two kinds of learning, learning skills. If you want to...

- Q: Which is more important, UG or CAD, in die design?

- You can think of it with your toes, ug.UG is it good?! First of all, the surface is refined, that is, UG modeling graduate, as for other, such as assembly engineering drawing, rendering, motion simulation, CAE, UG wiring, etc., you have mastered it? If I do, I can barely say, "fine."".UG is not a supplement, it is a mechanical minimum, as far as CAD is concerned, let alone the foundation of the foundation!

- Q: Will the CATIA software be used as two modules for mold design and NC machining?

- CATIA software in the automotive industry basically unified.Many industrial designs are not good enough for mold design and programming.

- Q: PLC programming in mold design and automation control

- All very well! There is no absolute good Human effort is the decisive factor., industry, only do good people. I'm an automation!

- Q: Does material forming and processing involve mold design and manufacturing?

- These are two different courses. Material forming and processing is a specialized basic course, and mold design and manufacture is a specialized elective course

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 2011 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | the United States, Germany, Japan, EU and other countries, the majority of users praise and love. |

| Company Certifications | ISO 9001:2008 PED Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 1,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality 100% Ductile Iron Casting Parts

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords