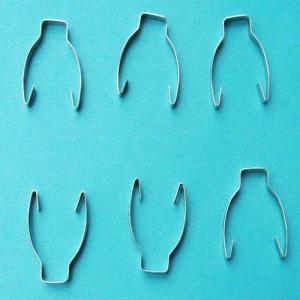

Sheet Metal Multi-Function High Precision Stamped Shrapnel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details Of High Precision Stamped Shrapnel

| Brand Name | MOULDSZ |

| Material | Brass, Stainless steel, BeCu, Carbon steel, bronze, Alloy spring steel, etc. |

| MOQ | 5000pcs |

Specification Of High Precision Stampd Shrapnel

| Material | Brass, Stainless steel, BeCu, Carbon steel, bronze, Alloy spring steel, etc |

| Mould | According customers request to build the mould. |

| Surface treatment | Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, and imitation gold-plated |

| Equipment | High-speed punching machines,Ordinary punching machines,Wire cutting machines,Milling machines ,etc |

Application Of High Precision Staped Shrapnel

Our products are widely used in many files , such as cellphone ,cumputer,switch ,lights ,communication devices ,auto parts etc.

Packaging & Delivery Of High Precision Staped Shrapnel

1.Packaging:with wooden case after fumigation or according to customer's requirement.

2.Delivery : according to your order quantity .

- Q:Mold design department, the general service department to find suppliers outside processing, but the general do not understand mold design, only to find lower prices suppliers, because suppliers are general affairs

- It seems that your factory is relatively large, so the plant system will not change easily.You must be on the mold design: 1 mold production requirements to write clearly, but also to write high; 2 must have mold maker test and suggestion right; 3 if the general recommended suppliers do not match, not the quality, you should react to the veterans by the boss, you decide to mold supplier

- Q:Does material forming and processing involve mold design and manufacturing?

- I used to learn die design and manufacture of professional mold design and manufacturing, including material forming and processing technology, but also even if the material forming and processing technology is a required course of mold design

- Q:Mold design and manufacture, post employment direction

- The outlook is good, but you have to study hard, diligent, dedicated, not afraid of hardship, not tired,

- Q:What are the types of moulds? What is the main job of mold design? Does mold design need to be opened, such as machining centers, CNC machine tools, or design before a single computer?

- Mold types are: stamping die, injection mold, casting mold, drawing die, die casting, and so on.The mold design mainly take a product of his abrasive finishing 2 out of the picture, and 3 dimensions.The mold designer just needs to draw a picture in front of the computer.

- Q:Which is more important, UG or CAD, in die design?

- I think, if in the mold design, UG or more important, UG belongs to large-scale software, in doing large-scale project use more! But the younger brother tells you, CAD is the foundation, this study is not good, that other not to mention, this belongs to a kind of routine, this learned well, other is good, learn much. I wish you happiness in your studies!

- Q:Which work is better for die design and five axis machining center programming? As soon as I graduate, these two positions can be done, mold design and five axis machining center

- Two in the concrete work has the very big correlation, the general design surface is more broad, the work content is also more abundant, as for two wages what, all in own level, cannot compare

- Q:What basic knowledge do CNC milling machine software programming and mold design require? Where do you start learning?

- It is recommended to operate machine tools first, and then to study!

- Q:The mould making and designing is more promising than the mechanical drawing (mechanical processing technician)

- Of course, mold making and design of the industry is promising, my brother-in-law is 26 years old this year, he was studying to be a mold design and production, the work in the company now, ten thousand 51 months, just as long as he is the design of the machine and sold a two thousand or three thousand Commission ```````` proposal making and design mold

- Q:What are the differences and connections between die design and mechanical design?

- Mold design for the school's professional is almost the same, learning mechanical design can also learn mold design second professional, learning mold design, but also need to learn the knowledge of mechanical design. The range of mechanical design including the relatively wide, want to learn is very difficult, we must rely on the work experience, to exercise their own, mold design is professional, learning is easier to learn, but only rely on mold design learning is insufficient. Likewise, experience is the most important

- Q:How about the employment prospects of mold design and manufacturing?

- It is learnt that, at present, China's mold enterprises generally encountered a shortage of talent, the shortage of qualified personnel has become a constraint to further improve the level of mold technology, mold industry further development bottleneck.

MOULDSZ is a versatile manufacturing factory - we specialise in supplying products made to customers` specification. The most important areas of our business are: manufacturing of stamping parts,hardware parts,shrapnels,stamping parts made of aluminium, copper & stainless steel, etc. Also auto parts,household applience spare parts like wash machine,air condition,refrige etc.

1. Manufacturer Overview |

|

|---|---|

| Location | Suzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2.5 Million - US$ 5 Million |

| Main Markets | Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central, America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | less than 50 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | about 500 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Sheet Metal Multi-Function High Precision Stamped Shrapnel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products