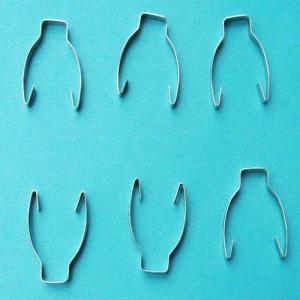

Stainless Steel Sheet Metal Fabrication with Zinc Plating

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000pieces pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details Of Sheet Metal Fabrication and Assembly

| Brand Name | MOULDSZ |

| Material | Stainless steel, iron , aluminum alloy, red copper, brass, bronze alloy are available. |

| Quality Control | ISO9001:2008 |

| MOQ | 2000pcs |

Specification Of Sheet Metal Fabrication and Assembly

| Material | Stainless steel, iron ( SPCC, SECC, SPTE, tinplate), aluminum alloy, red copper, brass, bronze alloy are available. |

| Surface Treatment | Powder coating, zinc plate ,polish |

| workshop for mnufacture | CNC Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, roll-in, surface treatment, and other General Fabrication Service |

| processing center | Stamping machine; Rolling machine; Turning machine; Milling machine; Grinding machine |

| Workmanship for manufacturing | CNC Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, roll-in, surface treatment, and other General Fabrication Service |

Our Advantage For Sheet Metal Fabrication and Assembly

1. Handling components of very tight tolerance and very complex geometry

2. Low MOQ (1pc is even acceptable in some special conditions)

3. Offering free and quick prototyping ( normally 1 week)

4. Delivery on time

5. Top quality guaranteed by skilled workers, managing system and status of facilities.

6. A series of secondary service available, like casting; forging; welding; heat treatment etc.

7. Offering consultancy service on components machining

8. Customized size and spec /OEM available

9. Near Ningbo and Shanghai, convenient transportation

Packaging & Delivery Of Sheet Metal Fabrication and Assembly

1.Packaging:with the pallet or do as your need .

2.Delivery : according to your order quantity .

- Q: Which is good for mold design and manufacture and software?

- In fact, we ignore, CATIA is the most powerful, but not yet universal. CATIA will definitely exceed UG PROE later

- Q: CAD die file for die pressing die design

- Then look at the mold design manual and get an assembly plan. It's about the same shape.

- Q: What are the prospects for NC machining and die design and manufacture?

- Just graduated, all apprentices, wages hundreds of pieces. Mold factory NC processing master wages are not high, Shenzhen 2000 to 2800 range, look at the technology, the longer you do, the higher the salary. NC programming salary of more than 3000, will not be higher than 1W, Shenzhen market price of about 4000, need to understand the die structure, knife, road, geometry, processing staff more in-depth knowledge of the mold. I read your courses, what schools are, even UG are not taught, you know, MasterCAM are almost eliminated, and if it is designed, but also to understand UG, PLO/E can design, but many factories are using UG. Learn mold design graduate apprentice apprenticeship assembly master fitter wages three thousand or four thousand. Sitting office design, you must be proficient in the structure of the mold, so just graduated is not competent, the software will be UG, CAD, of course, other software will be good, more than 3500 of wages. I was in accordance with the Shenzhen market, the person you are at school and professional think clearly, do not love the profession do not report, don't look at the design and programming of high wages, they are fitter from ah CNC operator step by step up, even after the employees do not stop learning, because the school did not learn what (that we graduated eighty percent students left). For your choice, you think you are a man of perseverance, as far as I say, consider it. I wish you happy.

- Q: How about the employment prospects of mold design and manufacturing?

- Mold talent salary rise. Senior mechanic because many enterprises are difficult to recruit skilled personnel salary, leading to the rising trend, such as the general salary mold design professionals 3000 yuan, NC personnel monthly salary of 3500 yuan, a monthly salary of senior workers familiar with the design, processing, modeling the whole operation process of more than 5000 yuan, of which more skills good personnel salary over a million yuan is not uncommon.

- Q: Attention should be paid to improvements in die design as well as improvements in EDM

- The discharge processing on the mold is a lot of processing sharp corners, narrow groove, deep hole what, in order to ensure the accuracy of processing, roughness, in the size of the electrode, and finally finishing the current parameters on the next effort! It is better to read a book than to read it. Go to the original school database and find it convenient

- Q: Learn die design, what information books to buy good?

- Learning to buy only a little software books, learn to learn UG and CAD. It's hard to completely learn by self-study, and many practical experiences and technical books are not available!

- Q: What's the future of the mold?

- Learning a skill will at least be respected. The older the industry, the more valuable it is

- Q: Consult the steps to learn the die design

- There are many kinds of moulds. Which one is good to help you?. For example, injection molding, etc., generally start with 3D modeling.

- Q: The mould making and designing is more promising than the mechanical drawing (mechanical processing technician)

- Each one has his good points, you'll want to look at how to develop, if you want to work in the factory is of course design and production mold is good, if later want to study after a period of time to do their own boss or mold technician is better. But even the mold design and design can not be fifteen thousand, plus commission, the kind of basic no, even if there is only 1/10000, almost.

- Q: PLC programming in mold design and automation control

- All very well! There is no absolute good Human effort is the decisive factor., industry, only do good people. I'm an automation!

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2.5 Million - US$ 5 Million |

| Main Markets | Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central, America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | less than 50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | about 500 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Stainless Steel Sheet Metal Fabrication with Zinc Plating

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000pieces pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords