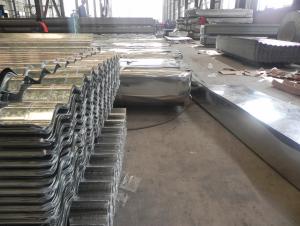

GAVANIZED STEEL MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GAVANIZED STEEL mesh is made of hot-dip zinc coated steel sheet,

It is used to be the material of untake out formwork for concret, widely used as plaster backing on ceilings, walls and stud partitions. Rib Lath is also ideal for refurbishing damaged or aged masonry walls when a key for rendering is not certain due to disintegration or softening of the wall face.

Material:Hot-dipped galvanized sheet

Application:

Construction formwork mesh as the concrete permanent assembly

free sheet is much convenient for engineering design and processing;

Construction formwork mesh is widely used in tunnels,bridges and valve system and so on to make the process of construction much more fast and stable.

ZINC COATING: G50 WEIGHT: 4.6KG/SHEET

- Q: What are the different types of surface patterns available for steel sheets?

- There are several different types of surface patterns available for steel sheets, including smooth, textured, embossed, diamond, and perforated patterns.

- Q: Are steel sheets resistant to UV radiation?

- No, steel sheets are not resistant to UV radiation.

- Q: What are the different types of steel sheet surface coatings for corrosion resistance?

- There are several types of steel sheet surface coatings available for corrosion resistance, including galvanized coatings, zinc-rich coatings, aluminum coatings, and organic coatings such as paint or epoxy. Each coating offers unique benefits and application suitability depending on the specific requirements and environmental conditions.

- Q: What is the difference between a galvanized and aluminized steel sheet?

- A galvanized steel sheet is coated with a layer of zinc to protect it from rust and corrosion, while an aluminized steel sheet is coated with a layer of aluminum-silicon alloy for enhanced heat resistance.

- Q: Are the steel sheets perforated or solid?

- Perforation has been applied to the steel sheets.

- Q: What are the different types of steel sheets?

- There are various types of steel sheets available, including hot rolled steel sheets, cold rolled steel sheets, galvanized steel sheets, and stainless steel sheets.

- Q: What are the different profile options available for steel sheets?

- Some of the different profile options available for steel sheets include corrugated, ribbed, standing seam, trapezoidal, and flat profiles. These profiles are designed to offer various benefits such as enhanced strength, improved water drainage, and aesthetic appeal for different applications in construction and roofing.

- Q: Can steel sheets be used for staircases?

- Yes, steel sheets can be used for staircases. Steel sheets are commonly used as the base material for staircases due to their strength, durability, and versatility. They can be fabricated into different shapes and sizes to create sturdy and visually appealing staircases.

- Q: Can steel sheets be customized according to specific requirements?

- Yes, steel sheets can be customized to meet specific requirements.

- Q: What is the difference between a hot rolled and cold rolled stainless steel sheet?

- The main difference between a hot rolled and cold rolled stainless steel sheet lies in the production process. Hot rolled stainless steel sheets are made by heating a stainless steel slab above its recrystallization temperature and then rolling it through a series of rollers until the desired thickness is achieved. This process results in a rough, scaled surface with a characteristic oxide layer. On the other hand, cold rolled stainless steel sheets are produced by further processing the hot rolled sheets. The hot rolled sheets are first annealed, which involves heating them and then cooling them slowly to regulate the microstructure and remove any stresses. After annealing, the sheets are cold rolled, which means they are passed through a set of rollers at room temperature to achieve the desired thickness. This process results in a smoother, more refined surface with improved mechanical properties. In summary, hot rolled stainless steel sheets have a rough surface and are less precise in terms of thickness, while cold rolled stainless steel sheets have a smoother surface and are more precise in terms of thickness. Cold rolled sheets also tend to have better mechanical properties due to the additional processing steps involved.

Send your message to us

GAVANIZED STEEL MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords