Aluminum honeycomb panel4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

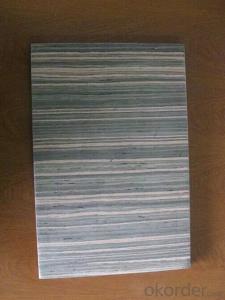

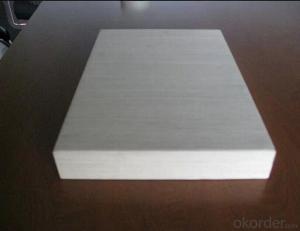

Aluminum honeycomb panels, suitable for civil building, vehicle decoration etc.. Is the application of aviation, aerospace materials in the field of civil building. The whole process is completed in modern chemical plant, using hot press molding technology, due to high thermal conductivity aluminum skin and honeycomb value between the inner and outer aluminum skin, thermal expansion and contraction synchronization; a small hole honeycomb aluminum skin, make board inside gas can flow freely; slidably mounted in heat bilges cold shrink button system does not cause structural deformation

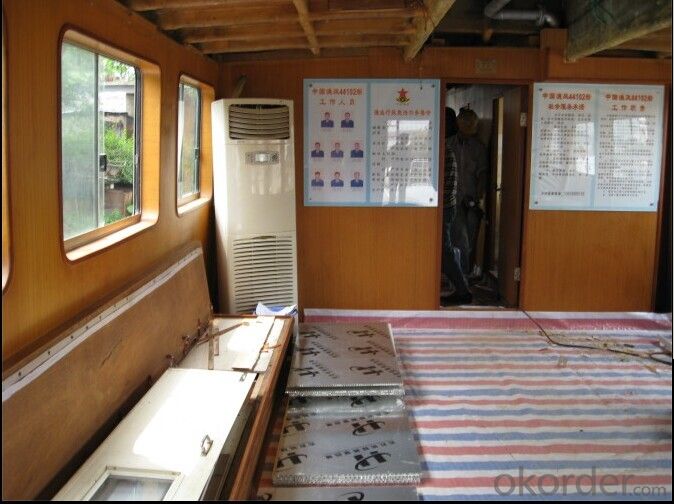

Use

(1) the building curtain wall and external wall hanging board

(2) interior decoration project

(3) billboard

(4) the ship building

(5) the aviation manufacturing industry

(6) indoor partition and merchandise display platform

(7) commercial truck and container vehicle car body

(8) the bus, train, subway and rail transit vehicles

(9) on very strict environmental requirements of modern furniture industry, aluminum honeycomb board to do the processing of furniture materials, is to choose a good material for the new century, its green quality completely non-toxic, let the furniture business in the processing of furniture, the less unnecessary environmental program; in addition, aluminum honeycomb panel the panel can be diversified such as wood, aluminum plate, gypsum board, Dali natural stone, can be made into honeycomb panel, easy material selection.

(10) aluminum honeycomb board partition: partition aluminum honeycomb panel, broke the previous traditional partition model, with its noble, pure and fresh, style style, won the middle and high-grade office space market share.

The performance advantage

(1) the fire: Aluminum incombustible material.

(2) corrosion: aluminum honeycomb panel is coated with epoxy fluorocarbon treatment, with strong corrosion resistance. Salt fog spray for 48 hours without pinholes, cracks, no blistering.

(3) environmental protection: honeycomb plate belongs to pure aluminum made products, volatile any harmful gases, no radiation and can be completely recycled, environment-friendly products 100 percent.

(4) aluminum honeycomb board is easy to dismantle and remove the plate assembly, not bad. Because of its light weight, easy to transport solid can be transported to different places and repeated utilization. This is the other partition plate can not match.

- Q: 28 silk 4MM aluminum plate how much money, use it to do the outer wall about how much money

- Asked by the 28 wire, in fact, is the industry said 0.30 mm or 30 wire, 4 cm 30 silk wall aluminum plate price, the first floor of the more reliable .90-160 yuan / square meters range. Do external walls often do fluorocarbon coating.

- Q: Company decoration use, I would like to ask the center line of well-known brand of aluminum slab board, aluminum plate which brand? What is the price?

- Medium, Chinese auspicious .. auspicious classic .. auspicious good beauty .. Baiyun auspicious (domestic retail major brands)

- Q: Aluminum veneer and aluminum-plastic plate which is good? Will aluminum veneers corrode?

- Aluminum-plastic plate, also known as aluminum-plastic composite panels

- Q: OKorder aluminum-plastic composite board where to sell?

- Cloud like building materials have aluminum-plastic composite board sales

- Q: Will the aluminum curtain wall refers to the metal aluminum curtain wall, or aluminum veneer aluminum-plastic curtain wall?

- In general, aluminum curtain wall refers to the aluminum veneer curtain wall, but now also refers to the aluminum honeycomb curtain wall, you can according to your needs to find suppliers, if the need for aluminum veneer, aluminum honeycomb products can find Reynold Aluminum veneer manufacturers, their product quality is very good oh

- Q: Are there any differences between aluminum slabs and aluminum panels?

- Aluminum plate is pure aluminum, mainly used for ceiling. Aluminum-plastic board full name of aluminum-plastic composite panels, use more widely.

- Q: Does the production process produce toxic substances? What is the impact on the body? Does the production of coated aluminum also produce toxic substances?

- Dust hazards Aluminum plants in the production process of dust mainly aluminum oxide dust, petroleum coke dust, asphalt dust. Alumina dust mainly exists in the electrolytic plant, the alumina storage and transportation system; the calcining section of the feeding system, nesting system, calcined after the section of the kneading machine, preheating screw machine and milling system dust and asphalt smoke; There are asphalt smoke generated; residual processing section of the coarse crushing, ingredients, screening and other processes are dust generated. Crane driver, electrolysis workshop workers, carbon powder broken, screening and other workers by the dust hazard. According to TJ36-79 "industrial enterprise design health standards" provides that the workshop the maximum allowable concentration of harmful substances in the air, the dust in the production of alumina dust should not exceed 6mg / m3; other dust (when the free silica content of 10% ) Shall not exceed 10mg / m3.

- Q: That is to say if you buy 10 standard size 1220 * 2440 aluminum panels about 3 square meters need to buy the number of universal glue, the proportion of their construction between the number?

- 5 liters need 3 barrels is enough. Generally a barrel of glue can stick 3-4 sheets.

- Q: On the report of the project price per square meter engineering requirements is to use 50 * 5 angle iron keel with 4mmA grade aluminum-plastic plate dry hanging

- Main materials: aluminum-plastic composite panels, profile skeleton, embedded parts, connectors, caulking sealing materials and fasteners. Profile skeleton are: aluminum alloy frame skeleton and steel skeleton, skeleton material selection to meet the design requirements, skeleton selection specifications and materials to meet national standards and related standards. Embedded parts and connectors: skeleton anchorage generally used embedded parts or post-embedded parts, post-embedded parts to meet the design requirements, and in the field to do pull test; steel plate connector and non-homogeneous skeleton connection, the middle To pad the organic material pad, in order to avoid electrochemical corrosion.

- Q: How to deal with the leakage of aluminum-plastic panels

- If the aluminum-plastic plate itself is hard to pierce or peel a class, then you need to replace the material.

Send your message to us

Aluminum honeycomb panel4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords