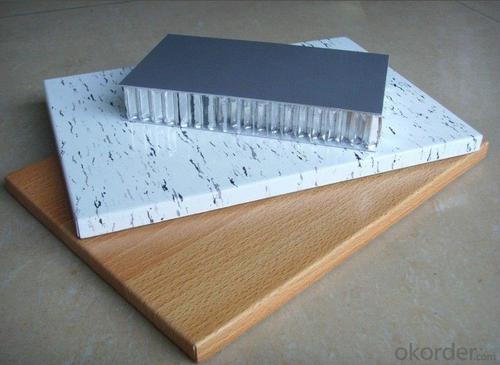

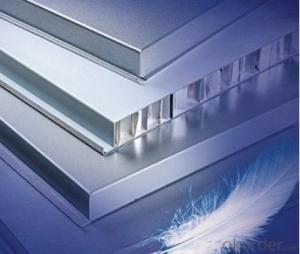

Aluminum honeycomb panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

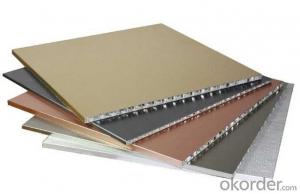

Aluminum honeycomb panels, suitable for civil building, vehicle decoration etc.. Is the application of aviation, aerospace materials in the field of civil building. The whole process is completed in modern chemical plant, using hot press molding technology, due to high thermal conductivity aluminum skin and honeycomb value between the inner and outer aluminum skin, thermal expansion and contraction synchronization; a small hole honeycomb aluminum skin, make board inside gas can flow freely; slidably mounted in heat bilges cold shrink button system does not cause structural deformation

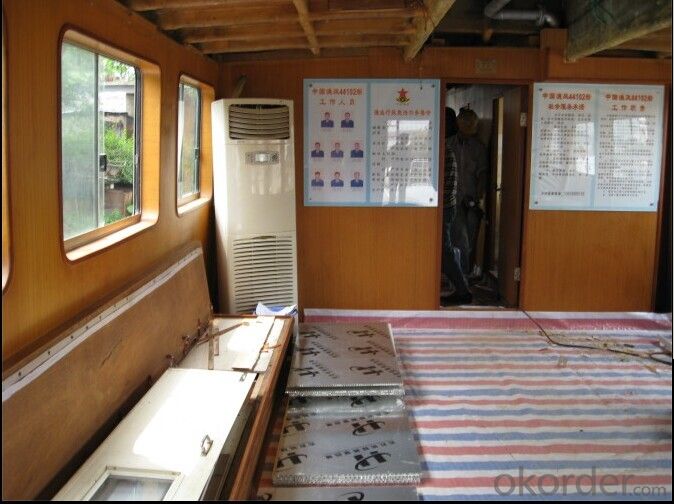

Use

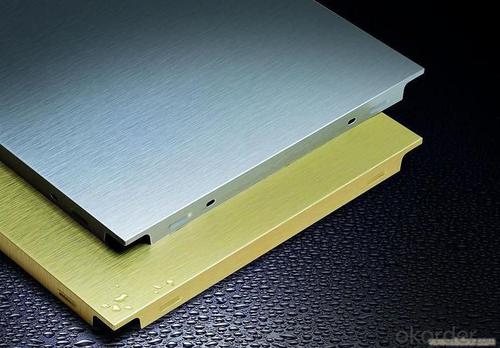

(1) the building curtain wall and external wall hanging board

(2) interior decoration project

(3) billboard

(4) the ship building

(5) the aviation manufacturing industry

(6) indoor partition and merchandise display platform

(7) commercial truck and container vehicle car body

(8) the bus, train, subway and rail transit vehicles

(9) on very strict environmental requirements of modern furniture industry, aluminum honeycomb board to do the processing of furniture materials, is to choose a good material for the new century, its green quality completely non-toxic, let the furniture business in the processing of furniture, the less unnecessary environmental program; in addition, aluminum honeycomb panel the panel can be diversified such as wood, aluminum plate, gypsum board, Dali natural stone, can be made into honeycomb panel, easy material selection.

(10) aluminum honeycomb board partition: partition aluminum honeycomb panel, broke the previous traditional partition model, with its noble, pure and fresh, style style, won the middle and high-grade office space market share.

The performance advantage

(1) the fire: Aluminum incombustible material.

(2) corrosion: aluminum honeycomb panel is coated with epoxy fluorocarbon treatment, with strong corrosion resistance. Salt fog spray for 48 hours without pinholes, cracks, no blistering.

(3) environmental protection: honeycomb plate belongs to pure aluminum made products, volatile any harmful gases, no radiation and can be completely recycled, environment-friendly products 100 percent.

(4) aluminum honeycomb board is easy to dismantle and remove the plate assembly, not bad. Because of its light weight, easy to transport solid can be transported to different places and repeated utilization. This is the other partition plate can not match.

- Q: What are the differences between fire-resistant aluminum-plastic panels and ordinary aluminum-plastic plates? What are the standards for fire protection on aluminum flooring for business premises?

- The biggest difference between the two is that the former has fire performance,

- Q: Meizhou how to sell outdoor aluminum plate? Please contact the contact, QQ and so on

- Located in Shunde: Guangdong Li Kyle Industrial Co., Ltd. specializing in the production of "Lee Kyle card" "Auspicious licensing" aluminum-plastic panels, aluminum veneer. Contact in space.

- Q: How to identify the quality of aluminum-plastic plate?

- And then cut a piece of the sample, boiled in boiling water for ten minutes, and then come out to put the refrigerator in the frozen one or two hours, if there is time to repeat more than a few times, and then hand or tools to expose the two sides of the aluminum, Opened the description of the quality is relatively poor, if it is not easy to open that excellent quality, which mainly depends on the temperature of hot and cold on the impact of aluminum panels.

- Q: How to paste the wallpaper on the aluminum plate

- No problem, sticky bar but to choose a good glue, the aluminum plate will not be damaged

- Q: How to install the aluminum-plastic panel ceiling?

- The more common installation method is to directly through the self-tapping screws in the aluminum plate above the keel, so there will be nail caps, but can be secretly fight. This is relatively easy.

- Q: All kinds of sheet prices, professionals know? To detail the point (wood core board, Jiuli mix, decorative panels, aluminum panels, fire board, etc.), sincere thanks

- 9% single-sided 82 yuan, double-sided 92 yuan; 12% single-sided 116 yuan, double-sided 126 yuan; 15% of the price of melamine sheet, 5% Single-sided 138 yuan, 18 yuan single-sided 148 yuan, double-sided 158 yuan; 18 PCT single-sided 169 yuan, single-sided 179 yuan;

- Q: Will the aluminum veneer replace the aluminum plate?

- Aluminum veneer and aluminum-plastic plate as has been applied for decades of metal curtain wall materials for our production and life has made a significant contribution. Aluminum veneer appeared the earliest, the majority of consumers generally recognized and welcomed, but to the sixties and seventies of last century, aluminum-plastic composite panels appeared, and quickly occupied a large part of the global market. Although the color of aluminum veneer can be arbitrarily selected and the color of aluminum-plastic plate varieties less, although the life of aluminum veneer far more than the life of aluminum-plastic plate, although the anti-wind pressure deformation of aluminum veneer is better than the anti- Wind pressure deformation, although the aluminum veneer construction process is also much simpler than the aluminum-plastic plate, and the cost of aluminum veneer is higher than the aluminum-plastic plate, while the aluminum plate easy to recover the fire will not pollute the environment and aluminum Once the fire will produce toxic gases caused by air pollution.

- Q: I do paint, the main would like to know about the price and details of aluminum-plastic panels, paint and do what is the place to do different? What are their characteristics? The best point can be detailed, I can not ask that there is time to the best details! The The Thank you

- Application effect, the aluminum plate in accordance with industry evaluation will be more fashionable than the use of paint some high-end fashion, and a building brush paint will feel inadequate level. Of course, in the surface flatness, decorative lines, weatherability and maintenance of renovation will be different.

- Q: OKorder Huayuan Fluorocarbon aluminum plate aluminum thickness 50mm each price is how much? Best to have pictures!

- Not so thick aluminum plate, there is no such a thick aluminum plate it.

- Q: Curtain wall sun room stone hit glass hit wood carpentry workers

- Do the most suitable for glass glue I did such a project maintenance

Send your message to us

Aluminum honeycomb panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords