aluminum honeycomb panels and sandwich panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 888888888 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum honeycomb panel:

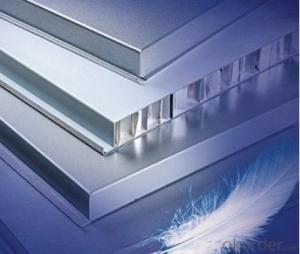

Aluminum honeycomb panels using the "sandwich" structure, surface treatment of aluminum alloy sheet fluorocarbon roll, the middle is in line with the National Aeronautics and aluminum honeycomb core standards. From Germany to introduce the use of sandwich boards for the production process --- continuous hot technology, chip technology hot, room temperature composite technology, specializing in the production of such products. So that the product has a more pronounced excellent properties, are widely used in building walls and interior decoration。

Material:

The main panel 3003 h24 series of magnesium alloy or magnesium alloy 5052 h24 series aluminum base material, 0.7 1.0 mm fluorocarbon roller plate thickness of the panel, the plate thickness of 0.5 1.0 mm, general choice 10 to 25 mm thickness. Use 3003 h24 hexagonal honeycomb core sandwich core material, the thickness of aluminum foil 0.04 0.06 mm, can fully meet the design and production needs of custom aluminum honeycomb core.

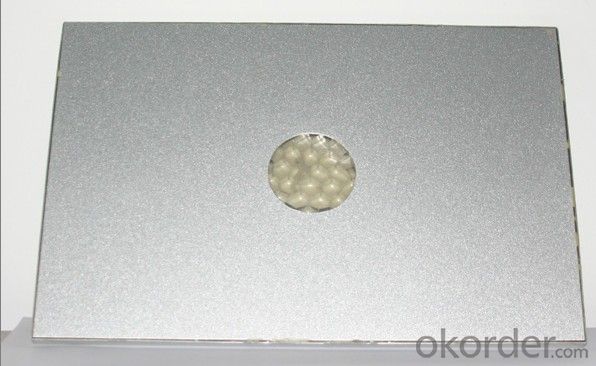

Aluminum honeycomb panel features:

★ high strength.

★ stiffness.

★ light weight.

★ good surface flatness.

★ fire performance is good: B1 level.

★ noise effects: air sound insulation 29dB.

★ good insulation: thermal conductivity 0.1613W / (m.k).

★ surface using paint roller coating technology: 70% of fluorocarbon paint, weathering wall, with self-cleaning capability.

★ aluminum honeycomb panels have good temperature resistance: when used in different geographical environment -40 ℃ to + 80 ℃, according to special requirements, can reach 100 ℃.

★ environmental protection, aluminum honeycomb panels without separation or classification can be completely recycled.

Aluminum h oneycomb panel product application areas:

Buildings and structures: roofs, facades and wall cladding, ceiling / partition / door, interior {walls, floors}

Elevator: bridge car negatives, siding, roof

Exhibition, display: exhibitions, display card production, store decoration

Transportation: commercial vehicles [envelope, car bottom], ship bilge {version} bulkhead, rail, rail vehicles {negatives, siding} public, special transport vehicles {container volume, transport trough}, aircraft industry

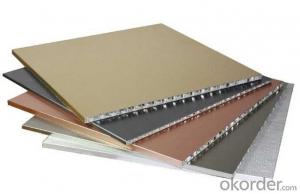

Aluminum honeycomb Specifications:

Thickness: 6mm-560mm

Al thick: 0.5-2.5mm

Width: 800 ~ 1700mm

Length: any length

Color: do special color

Core: aluminum honeycomb core 3003H19 or 5052

Coating: fluorocarbon coating

Workshop Photos

- Q: I would like to ask, 50 thick metal sandwich panels per square meter generally have multiple ah?

- This depends on your use, generally do sandwich board bulk density in accordance with the 120kg / cubic meter to count, the weight of each square about 6kg, plus 2 side of the steel plate, up to 6.5kg or so! [Rockwell Rock wool / Structural rock wool composite panel

- Q: There is a phone call

- The price of polyurethane sandwich panels have the thickness of the polyurethane sandwich panels used and the color and thickness of the color steel plate to determine the price of its polyurethane sandwich panels. The common polyurethane sandwich panel specifications are 50,75,100,150,200 thick Of the price between 90-120 yuan. Manufacturers can see my picture, you need the above contact information. Here to tell you degree mother and give me a shield, and I easily I, to high score ah!

- Q: Is the polyurethane sandwich panel and foam board flame retardant?

- To see if there is no added flame retardant

- Q: Would you like to check the flame retardant type of the metal surface rock wool sandwich panel of the activity board room?

- Surely, the requirements of the roof rock wool board will be higher, our company to do the roof rock wool board, there are inspection reports.

- Q: Color steel sandwich panel door how to do?

- Color steel sandwich panel door how to do? This large number of doors in the clean room area, it has ready-made aluminum alloy assembly can be. A small amount can be made with the annex to the material package, with riveting can be.

- Q: Aluminum magnesium manganese composite sandwich panel 90 degrees right angle how to fold

- Certainly the aluminum magnesium manganese plate light, the proportion of aluminum magnesium manganese plate is 4.71, the proportion of color steel plate is 7.85.

- Q: Color steel sandwich panels can be used for many years

- If it is GB double-sided 0.45MM Baosteel foam 16KG / M, then 25 years certainly no problem

- Q: Color steel polyurethane sandwich panels can do the paint room cut off you

- Of course you can, more expensive, generally recommended with rock wool

- Q: Will the rock wool sandwich board which manufacturers better?

- I know, you can consider Zhejiang Bo Ya building materials, production Yanmian sandwich panels, all kinds of sandwich panels,

- Q: What does this product represent?

- Representative of the color steel sandwich panel model

Send your message to us

aluminum honeycomb panels and sandwich panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 888888888 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords