Aluminum 1100 Plate

Aluminum 1100 Plate Related Searches

1100 Aluminum Plate 1100 Series Aluminum Plate 1100 Aluminum Plate Suppliers 2011 Aluminum Plate 11 Gauge Aluminum Plate 1100 Aluminum Foil 1050 Aluminum Plate 1 Aluminum Plate Aluminum Coil 1100 Aluminum Square Plate Aluminum Round Plate 1100 Aluminum Coil Aluminum Surface Plate Aluminum Metal Plate Aluminum Cooking Plate 1 Inch Aluminum Plate Aluminum Base Plate Aluminum Nitride Plate Aluminum Mold Plate Aluminum Paper Plate Aluminum Cold Plate 1060 Aluminum Plate 12mm Aluminum Plate Aluminum Bronze Plate Aluminum Flat Plate Aluminum Motor Plate 1 4 Aluminum Plate Aluminum Oxide Plate 1 Thick Aluminum Plate Aluminum Wall PlateAluminum 1100 Plate Supplier & Manufacturer from China

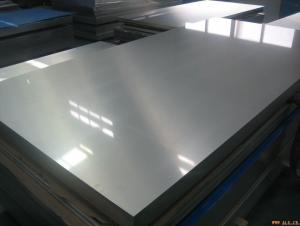

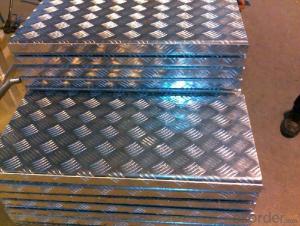

Aluminum 1100 Plate, a highly versatile and widely used product, is made from pure aluminum with a minimum of 99.00% aluminum content. This type of aluminum plate is known for its excellent formability, weldability, and corrosion resistance, making it suitable for a variety of applications. In various industries, from construction to automotive, Aluminum 1100 Plate is utilized for its lightweight properties and strength, offering a reliable solution for numerous projects and components.The usage scenarios for Aluminum 1100 Plate are vast, encompassing everything from decorative applications to structural components. It is commonly used in the manufacturing of chemical equipment, food processing machinery, and electrical conduits due to its non-magnetic and non-sparking characteristics. Additionally, its malleability makes it an ideal choice for deep drawing and stamping processes, further broadening its range of applications.

Okorder.com stands as a prominent wholesale supplier of Aluminum 1100 Plate, boasting a substantial inventory to cater to the diverse needs of clients. With a commitment to quality and customer satisfaction, Okorder.com ensures that the aluminum plates they provide meet the highest industry standards. Their extensive stock allows for quick turnaround times and efficient delivery, making them a reliable choice for businesses seeking a dependable source for their aluminum plate requirements.

Hot Products