4x8 Sheets of Aluminum Siding - Aluminum Sheet 1050 1060 1070 1100 1235 1 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification

Alunimiun Sheet

ALLOY: AA1*** (AA1050,AA1060,AA1070,AA1100 etc.)

AA3*** (AA3003,AA3004,AA3005,AA3105 etc.)

AA5*** (AA5052,AA5083,AA5754 etc)

AA8*** (AA8011,AA8006 etc)

TEMPER: H14,H16,H18,H22,H24,H26,H32,O/F

THICKNESS: 0.2mm-100mm

WIDTH: 30mm-1700mm

STANDARD: GB/T 3880-2006

Special specification is available on customer's requirement

2. Advantage

Best quality!

3. Description

Aluminium is oxidized by water at temperatures below 280°C to produce hydrogen, aluminium hydroxide and heat:2 Al + 6 H2O → 2 Al(OH)3 + 3 H2

This conversion is of interest for the production of hydrogen. Challenges include circumventing the formed oxide layer, which inhibits the reaction and the expenses associated with the storage of energy by regeneration of the Al metal.

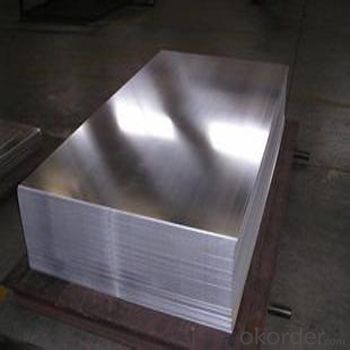

4. Pictures

5. FAQ

1)what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

2)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3)Can we supply samples?

Yes, we can!

- Q: Can aluminum sheets be used for packaging purposes?

- Yes, aluminum sheets can be used for packaging purposes. They are commonly used in the packaging industry due to their lightweight, corrosion-resistant, and malleable properties. Aluminum sheets can be easily formed into various shapes and sizes, making them ideal for packaging products such as food, beverages, pharmaceuticals, and cosmetics. Additionally, aluminum provides a protective barrier against moisture, oxygen, and light, ensuring the quality and longevity of the packaged goods.

- Q: This question asks about the various types of aluminum sheets that are commonly used for roofing purposes, including their specific applications and characteristics.

- <p>Aluminum sheets used for roofing come in various types, each with unique properties and applications. The main types include: 1) Corrugated Aluminum Sheets: Known for their strength and durability, these are often used in commercial and industrial roofing due to their ability to withstand harsh weather conditions. 2) Standing Seam Aluminum Sheets: These provide a sleek, clean look and are favored for their water-resistant properties, making them ideal for residential and architectural applications. 3) Flat Aluminum Sheets: Offer a smooth surface finish and are used where a uniform appearance is desired. 4) Perforated Aluminum Sheets: These have small holes that allow for ventilation, reducing heat build-up and are used in areas requiring natural light and air circulation. 5) Embossed Aluminum Sheets: With a textured surface, they provide added rigidity and are used in both residential and commercial settings for their aesthetic appeal. Each type is chosen based on the specific needs of the roofing project, such as design, weather resistance, and longevity.</p>

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- No, 101 aluminum sheets are not suitable for chemical transfer piping. Aluminum is generally not recommended for handling certain chemicals due to its reactivity and potential for corrosion. It is more commonly used in industries that require lightweight materials and good thermal conductivity, such as aerospace or construction. For chemical transfer piping, it is advisable to use materials that are resistant to corrosion and can withstand the specific chemicals being transported, such as stainless steel, PVC, or high-density polyethylene (HDPE).

- Q: I am looking at buying a used 1983-84 Eldorado but have read some things about the reliability of the aluminum engine. Any thoughts? Thanks.

- 1984 Cadillac

- Q: Are aluminum sheets suitable for architectural louvers?

- Indeed, aluminum sheets prove to be a fitting option for architectural louvers. The advantageous properties of aluminum make it a favored material for louvers in the field of architecture. To begin with, aluminum possesses the desirable combination of being lightweight and yet sturdy, which makes it an ideal material for architectural louvers. It has the ability to withstand external forces such as wind and various weather conditions while maintaining its structural integrity. This becomes crucial for louvers as they are required to provide ventilation and airflow, all the while retaining their form and functionality. Furthermore, aluminum displays a high level of resistance against corrosion and rust. Considering that louvers are frequently exposed to outdoor elements like rain, moisture, and sunlight, the corrosion resistance of aluminum ensures the longevity and durability of the louvers, even in harsh environmental conditions. In addition, aluminum is an adaptable material that can be easily customized and fabricated into different shapes and sizes. This flexibility allows architects and designers to fashion louvers with unique designs and configurations that suit the specific requirements of the building. Aluminum louvers can be personalized to optimize airflow, control light, and enhance aesthetic appeal. Moreover, aluminum stands out as a sustainable and environmentally friendly material. It is widely recyclable, which means that aluminum louvers can be easily repurposed or reused at the end of their life cycle. Opting for aluminum in the construction of architectural louvers aligns with sustainable building practices and contributes to the overall reduction of environmental impact. In conclusion, aluminum sheets are indeed a suitable choice for architectural louvers. Their lightweight yet robust nature, resistance to corrosion, ability to be customized, and sustainability make them an excellent option in terms of functionality, durability, and aesthetics.

- Q: This question asks for the duration aluminum sheets can last and how their lifespan compares to other materials.

- <p>The lifespan of aluminum sheets can vary depending on the environment and usage, but generally, they can last for several decades with proper care and maintenance. Aluminum's resistance to corrosion and weathering makes it a durable choice. Compared to other materials, aluminum is more durable than wood and many plastics, but it may not last as long as some high-quality stainless steels or certain types of stone. It's also lighter than steel, making it a popular choice for construction and manufacturing applications where weight is a concern.</p>

- Q: Can aluminum sheets be anodized for improved hardness?

- Anodizing aluminum sheets is a method to enhance their hardness. This process involves electrochemically forming a protective oxide layer on the surface of the aluminum. This oxide layer not only improves the sheet's ability to resist corrosion but also increases its hardness, making it more durable against wear and abrasion. The thickness of the oxide layer and, therefore, the hardness of the aluminum sheet can be precisely adjusted by carefully controlling the anodizing conditions, such as the type of electrolyte used, the applied voltage, and the duration of the process. Industries such as automotive, aerospace, construction, and electronics utilize anodized aluminum sheets because they require materials that possess both improved hardness and corrosion resistance.

- Q: Can aluminum sheets be used for flooring?

- Indeed, flooring can utilize aluminum sheets. Lightweight and sturdy, aluminum proves resistant to corrosion, rendering it an appropriate option for a range of flooring uses. Notably, aluminum sheets frequently find employment in industrial, commercial, and residential settings, encompassing warehouses, garages, kitchens, and outdoor areas. These sheets offer commendable strength, effortless installation, and minimal upkeep. Furthermore, aluminum flooring imparts a polished and contemporary aesthetic to any given space. Nevertheless, prudent consideration of factors like thickness, finish, and the unique demands of the flooring project becomes imperative prior to settling on aluminum sheets.

- Q: Are the aluminum sheets suitable for manufacturing chemical storage cabinets?

- Yes, aluminum sheets are suitable for manufacturing chemical storage cabinets. Aluminum is a strong and durable material that is resistant to corrosion, making it ideal for storing and protecting chemicals. It is also lightweight, which makes transportation and installation easier. Additionally, aluminum is non-reactive with most chemicals, ensuring the safety of the stored substances. Overall, aluminum sheets provide a reliable and efficient solution for manufacturing chemical storage cabinets.

- Q: This question asks about the typical duration an aluminum roof sheet can last before it needs to be replaced or repaired.

- <p>The lifespan of aluminum sheets for roofing can vary depending on the quality of the material, installation, and environmental factors. On average, a well-maintained aluminum roof can last between 20 to 50 years. High-quality aluminum roofing materials, when properly installed, can even exceed this range, offering a lifespan of up to 70 years. However, it's important to note that regular inspections and maintenance are crucial to extend the life of any roofing material, including aluminum.</p>

Send your message to us

4x8 Sheets of Aluminum Siding - Aluminum Sheet 1050 1060 1070 1100 1235 1 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords