Aluminum Sheet 1050 1060 1100 1.2Mm 3Mm 6Mm 2Mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

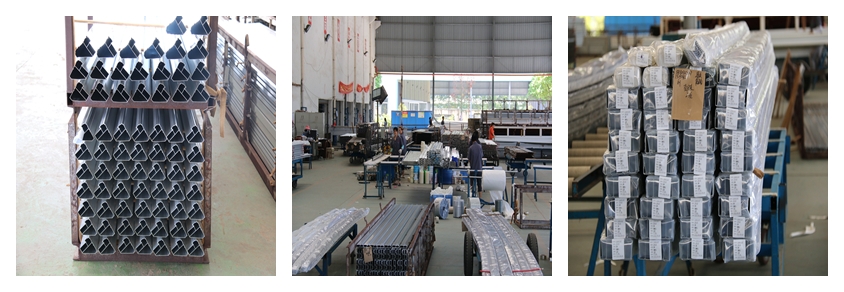

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: What is the typical machinability of aluminum sheets?

- Aluminum sheets are widely acknowledged for their excellent machinability. This is due to their relatively low density and softness, which make them easier to machine compared to other metals. Furthermore, aluminum exhibits good thermal conductivity, enabling efficient heat removal during machining. Its low melting point also reduces the likelihood of overheating. Moreover, aluminum demonstrates favorable chip formation characteristics, resulting in effortless chip removal and decreased tool wear. However, the machinability of aluminum may differ depending on factors like alloy composition, tempering, and surface finish. Nevertheless, aluminum sheets are generally considered to be highly machinable.

- Q: Are aluminum sheets suitable for architectural facades?

- Yes, aluminum sheets are highly suitable for architectural facades. They offer numerous benefits such as durability, lightweight construction, corrosion resistance, and versatility in design. Aluminum sheets can be easily shaped and formed into various sizes and shapes, allowing for creative and unique architectural designs. Additionally, their ability to withstand harsh weather conditions makes them a reliable choice for long-lasting facades.

- Q: Dear all, i'm having crack problem with bending aluminium sheet metal, anyone know than which type(Model) of aluminium sheet metal is suitable for bending, Thanks.

- All aluminum can be bent if u have the right equipment. I have no idea what you are using it for, so I can't give you specific advice. But, go with the lightest gauge aluminum that fits your purpose. The higher the gauge number, the thinner the aluminum is. 16 gauge aluminum is 1/16 thick, for example, but 18 gauge is thinner. Also, the temper of the material affects how easy it is to bend. 6063 aluminum is more malleable (easier to bend) than 6061.

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- No, 101 aluminum sheets are not suitable for chemical transfer piping. Aluminum is generally not recommended for handling certain chemicals due to its reactivity and potential for corrosion. It is more commonly used in industries that require lightweight materials and good thermal conductivity, such as aerospace or construction. For chemical transfer piping, it is advisable to use materials that are resistant to corrosion and can withstand the specific chemicals being transported, such as stainless steel, PVC, or high-density polyethylene (HDPE).

- Q: Can aluminum sheets be anodized with custom colors?

- Custom colors can indeed be applied to aluminum sheets through the process of anodizing. Anodizing involves the application of an electrochemical procedure that adds a protective oxide layer to the aluminum's surface, thereby enhancing its durability and resistance to corrosion. In this process, the aluminum sheet is submerged in an electrolytic solution while an electrical current is passed through it. This induces a controlled oxidation of the aluminum's surface, leading to the formation of a porous layer that can be colored with dyes to achieve desired shades and hues. By carefully selecting the appropriate dye, a wide array of custom color options can be achieved. Moreover, anodized aluminum sheets offer versatility as they can undergo additional treatments like laser engraving or printing to create distinctive designs and patterns. Therefore, they are highly suitable for a diverse range of applications in industries such as architecture, automotive, and electronics.

- Q: What is the flexural modulus of aluminum sheets?

- The flexural modulus of aluminum sheets refers to the measure of the stiffness or rigidity of the material when subjected to bending or flexural stress. It is a mechanical property that quantifies how well an aluminum sheet can resist deformation under applied force. The flexural modulus of aluminum sheets typically ranges between 69 GPa (gigapascals) to 79 GPa, depending on the specific alloy and temper. However, it is important to note that the flexural modulus can vary slightly based on factors such as thickness, heat treatment, and manufacturing processes. Aluminum is known for its excellent strength-to-weight ratio, making it a popular choice for various applications where lightweight and durable materials are required. Its relatively high flexural modulus allows aluminum sheets to maintain their shape and resist bending or flexing, making them suitable for uses such as aircraft structures, automotive components, and building construction. It is worth mentioning that the flexural modulus of aluminum can be enhanced by alloying elements or through heat treatment processes. For instance, certain aluminum alloys like 7075 or 2024 may exhibit higher flexural modulus values due to their increased strength and stiffness properties. In conclusion, the flexural modulus of aluminum sheets is an important mechanical property that determines their ability to withstand bending or flexural stress. It provides insight into the material's rigidity and helps engineers and designers select the appropriate aluminum alloy and thickness for various applications.

- Q: Can aluminum sheet be used for roofing?

- Yes, aluminum sheet can be used for roofing. Aluminum is a popular choice for roofing due to its numerous advantages. Firstly, aluminum is lightweight, making it easier to install and reducing the load on the structure of the building. Secondly, aluminum is highly durable and resistant to corrosion, which means it can withstand harsh weather conditions, such as heavy rain, snow, and UV radiation. Additionally, aluminum is non-combustible, making it a safe choice for roofing. Furthermore, aluminum is an environmentally friendly material as it is 100% recyclable, reducing its impact on the environment. Overall, aluminum sheet is a reliable and efficient option for roofing applications.

- Q: Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- i'm uncertain regardless of the incontrovertible fact that it must be relaxing, are you making thermite? i might guess which you would be able to artwork this out from the atomic weights of each, and taking the valencies under consideration - 2 aluminium atoms for 3 oxygen atoms. 2 iron atoms for 2 oxygen (a million:a million).

- Q: Are aluminum sheets suitable for electronic components?

- Indeed, electronic components can be accommodated with aluminum sheets. Aluminum, a metal that is both lightweight and durable, exhibits exceptional electrical conductivity. It finds frequent application in the fabrication of electronic housings, heat sinks, and circuit boards. Due to its malleability, aluminum sheets can be effortlessly machined, molded, and joined together, rendering them adaptable for a multitude of electronic purposes. Furthermore, aluminum possesses commendable thermal conductivity, enabling efficient heat dissipation, a vital feature for averting overheating in electronic devices.

- Q: Can aluminum sheets be used for decorative wall panels?

- Aluminum sheets are indeed suitable for decorative wall panels. As a versatile material, aluminum offers a wide array of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it perfect for both indoor and outdoor applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for limitless design possibilities. Moreover, aluminum can be enhanced in appearance and provided with extra protection against wear and tear through powder-coating or anodizing. Whether it's for residential or commercial spaces, aluminum sheets can impart a modern and stylish touch to any wall, rendering them a highly sought-after choice for decorative wall panels.

Send your message to us

Aluminum Sheet 1050 1060 1100 1.2Mm 3Mm 6Mm 2Mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords