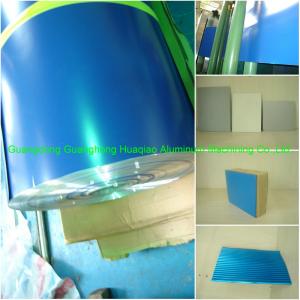

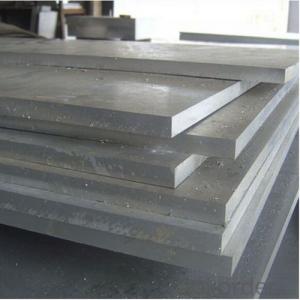

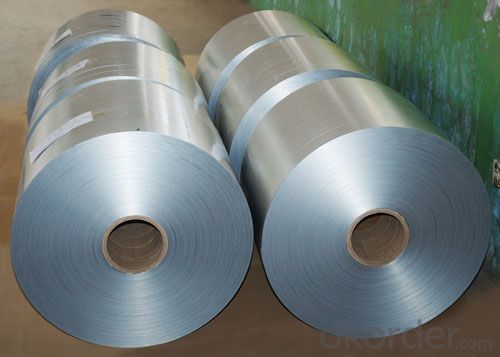

Flat Rolled Aluminum Coil Ohio - Alloy 6061 T6 China Distributor 2mm 3mm 4mm Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy 6061 T6 China Distributor 2mm 3mm 4mm Aluminum

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: What are environmentally friendly types of aluminum coil and do they exist?

- <p>Yes, there are environmentally friendly types of aluminum coil. These include recycled aluminum coils, which are made from aluminum that has been reprocessed and reused, reducing the need for new aluminum production and its associated environmental impact. Additionally, aluminum coils with a high recycled content are considered eco-friendly as they contribute to waste reduction and energy conservation. The production of recycled aluminum uses significantly less energy compared to virgin aluminum, making it a more sustainable choice.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing spring steel wire coils.

- <p>Spring steel wire coils offer several advantages such as high strength and durability, making them ideal for applications requiring resilience and resistance to deformation. They are also known for their excellent elasticity, which allows for consistent performance in dynamic applications. Additionally, spring steel wire coils can be easily formed into various shapes, providing versatility in design and functionality. However, they also have disadvantages, including potential for corrosion if not properly treated, and they can be more expensive than other types of wire due to the material's properties. Furthermore, spring steel wire coils may require specialized tools and equipment for handling and installation, adding to the cost and complexity of their use.</p>

- Q: Can aluminum coils be used in the production of kitchen utensils?

- Yes, aluminum coils can be used in the production of kitchen utensils. Aluminum is a popular choice for kitchen utensils due to its lightweight, durable, and heat-conducting properties. Aluminum coils can be easily shaped and molded into various utensil designs such as pots, pans, baking trays, and even cutlery. Additionally, aluminum is resistant to corrosion, making it suitable for contact with food and liquids. It is important to note that aluminum utensils may require a non-stick coating or a protective layer to prevent the reaction between aluminum and certain acidic or alkaline foods. Overall, aluminum coils are widely used in the production of kitchen utensils due to their versatility and practicality.

- Q: What are the thermal expansion properties of aluminum coils?

- The thermal expansion properties of aluminum coils refer to the way aluminum expands or contracts when exposed to changes in temperature. Aluminum generally has a high coefficient of thermal expansion, meaning it expands significantly when heated and contracts when cooled. This property allows aluminum coils to effectively conduct heat and transfer it to the surrounding environment.

- Q: The export aluminum volume is CIF. If there is no insurance policy, how will the customs premium be collected?

- The customs will not charge your premium the premium you can write but if you are a refund if there will be some impact because of the tax rebate minus the freight and insurance premium so you consider the premium but you can write less Never mind if you need shipping or shipping insurance declaration business can contact me oh

- Q: How are aluminum coils inspected for quality control?

- Aluminum coils are inspected for quality control through various methods including visual inspection, dimensional checks, and non-destructive testing techniques such as ultrasonic testing, eddy current testing, and X-ray inspection. These inspections help to ensure that the coils meet the required specifications, have no visible defects, and possess the desired mechanical properties before they are used in various applications.

- Q: I would like to order 25 micron diameter 99.99% Aluminum wire required to use for making electrical connections. Only several cm are needed, so I would like to purchase a small spool. Delivery ASAP preferable (overnight or two day shipping would be best). This wire will be attached by hand using epoxy and not using a wire bonder.

- If they can't help, try asking the tech support guys at the wirebond manufacturers and the tool manufacturers. KS in the US and Shinkawa in Japan used to be the big guys. You can search for ultrasonic bond tools. You can also check with superconducting research centers; several private and public ones. Researchers might loan you materials and/or bonding support. BTW, Al critical temp is reportedly about 1.2°K, pretty tough to get that cold! U/S bond wire has 1% silicon, partly for hardness, you can probably bond pure wire though. Key is breaking up the oxide. Maybe bonding at cold temps and/or in vacuum would work. Also, I doubt epoxy would be good or superconducting at the temps. Al filled epoxy is unreliable electrical conductor due to oxide formation. Will be a bear to handle such fine wires without a bonder! Good luck!

- Q: How are aluminum coils transported and packaged?

- Aluminum coils are typically transported and packaged using wooden crates or pallets. The coils are securely strapped or bundled together to prevent movement during transit. They are then loaded onto trucks or shipping containers for transportation, ensuring they are well-protected to avoid any damage or deformation.

- Q: I am a college student living in a private apartment and I use up lots of aluminium foils to cook and eat. I use aluminium foils as plates because I am too lazy to clean plates. I want to know how environment-unfriendly i am for doing so. How bad am I compared to the guy who keeps on drinking from cans without recycling them?

- Are you recycling them? If so it could be quite interseting as you are not using detergent and water to wash up? Who knows? How bad do you feel? I imagine that it's not great in the big scheme of things as re-using is the best option before re-cycling.

- Q: Which is more unhealthy the bleached parchment paper or the aluminum from the pan?

- If what you are cooking is going to stick to the foil pan, then use some parchment paper to prevent it. Otherwise, the purpose of foil pans are so you can use them and throw them away.

Send your message to us

Flat Rolled Aluminum Coil Ohio - Alloy 6061 T6 China Distributor 2mm 3mm 4mm Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords