Hot Rolled Checkered Steel Plate of High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot Rolled Checkered Steel Plate Description

Widely used in petrochemistry,chemistry,electricity,boiler and vessel manufacture,and could be made into reactor,

heat exchange facility,segregator,sphere vessel,oil tank,liquid gas storage tank,nuclear reactor press shell,turbine and other machines.

2.Main Features of the Hot Rolled Checkered Steel Plate

•Hot Rolled & Annealing

•Good Quality & Fast Delivery

•Competitive Price & Nice Service

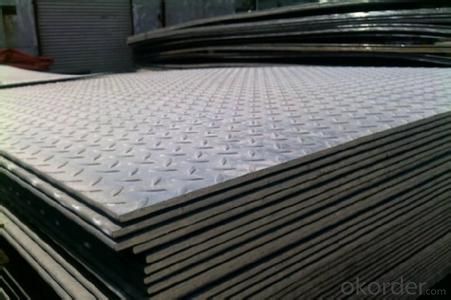

3. Hot Rolled Checkered Steel Plate Images

4. Hot Rolled Checkered Steel Plate Specification

Thickness | 2-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

Tehnique | Hot rolled;cold rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC |

Delivery time | Within 7-10 days |

5.FAQ of Hot Rolled Checkered Steel Plate

①Condition of Delivery

According to user requirements, can be Hot rolled, normalizing, tempering, normalizing and tempering, quenching and other delivery.

②Which Standard?

According to user requirements, can be delivered the following criteria: national standards, metallurgical industry standards, the United States ASTM, ASME standards, Japanese JIS, German DIN, British BS, European EN, the international ISO standards and the standards specific board and so on.

③What's the usage?

Making pipes, cold strip-welded pipes, cold-bent shaped-steel, bicycle structures, small-sized press-pieces and household decoration goods

- Q: Are steel sheets heat resistant?

- Yes, steel sheets are heat resistant. They have a high melting point and can withstand significant levels of heat without deforming or losing their structural integrity.

- Q: Are steel sheets affected by UV radiation?

- Yes, steel sheets can be affected by UV radiation. Over time, prolonged exposure to UV radiation can cause steel sheets to undergo a process called photo-oxidation, leading to degradation, discoloration, and potential loss of strength. To protect steel sheets from UV damage, they are often coated with specialized finishes or paints that contain UV stabilizers or inhibitors.

- Q: Can steel sheets be used for signage purposes?

- Indeed, signage purposes can be served by steel sheets. Their durability allows them to withstand harsh weather conditions, rendering them appropriate for outdoor signage. Various sizes and designs can be achieved by cutting, shaping, and welding the steel sheets, offering versatility in crafting personalized signage. To enhance aesthetics and ensure long-lasting quality, the steel sheets can be painted or coated with different finishes. Moreover, their sturdiness enables secure mounting, making them an excellent choice for large and heavy signage installations.

- Q: What are the different types of steel sheet alloys?

- There are various types of steel sheet alloys, including carbon steel, stainless steel, galvanized steel, and alloy steel.

- Q: What is the average lifespan of galvanized steel sheets?

- The average lifespan of galvanized steel sheets can vary depending on several factors such as the environment, maintenance, and usage. However, in general, galvanized steel sheets have a lifespan of 20 to 50 years. This lifespan can be extended with proper care, regular inspection, and maintenance practices. Galvanized steel sheets are known for their durability and resistance to corrosion, which contributes to their relatively long lifespan. Nonetheless, factors such as exposure to harsh weather conditions, extreme temperatures, and corrosive substances can affect the longevity of galvanized steel sheets. Therefore, it is essential to consider these factors and implement appropriate maintenance measures to ensure the maximum lifespan of galvanized steel sheets.

- Q: How much is 2 millimeters per square meter?

- GB two mm steel plate per square weight of about 15.7 kilograms, converted into per square should be 80-100 yuan.Steel plate is made of molten steel, cooled and compressed into flat steel. Steel plate by thickness, thin steel plate <4 mm (thinnest 0.2 mm), thick steel plate 4~60 mm, extra thick steel plate 60~115 mm. The steel plate is divided into hot-rolled and cold-rolled parts by rolling

- Q: Can steel sheets be used as a decorative material?

- Yes, steel sheets can be used as a decorative material. With its sleek and modern appearance, steel sheets can add a contemporary touch to various applications, such as interior and exterior design, furniture, wall panels, and more. Additionally, steel sheets offer durability, versatility, and low maintenance, making them a popular choice for decorative purposes.

- Q: Can steel sheets be used for mezzanine floors?

- Yes, steel sheets can be used for mezzanine floors. Steel is a commonly used material for constructing mezzanine floors due to its strength, durability, and ability to support heavy loads. Steel sheets can be used as the primary flooring material or as a subflooring layer, providing a stable and secure platform for various applications.

- Q: What is the average bending radius for steel sheets?

- The average bending radius for steel sheets can vary depending on the thickness and type of steel being used. However, a common range for the average bending radius of steel sheets is between 0.5 to 2 times the thickness of the sheet.

- Q: Can steel sheets be used for modular construction or prefabricated buildings?

- Yes, steel sheets can be used for modular construction or prefabricated buildings. Steel sheets offer high strength and durability, making them suitable for constructing modular or prefabricated buildings. They can be easily fabricated, assembled, and disassembled, allowing for efficient construction processes. Additionally, steel sheets provide excellent resistance to fire, pests, and extreme weather conditions, making them a popular choice for modular construction or prefabricated buildings.

Send your message to us

Hot Rolled Checkered Steel Plate of High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords