Aluminum Sheets Perforated Embossed Aluminum Stucco Plate for Refrigeratory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

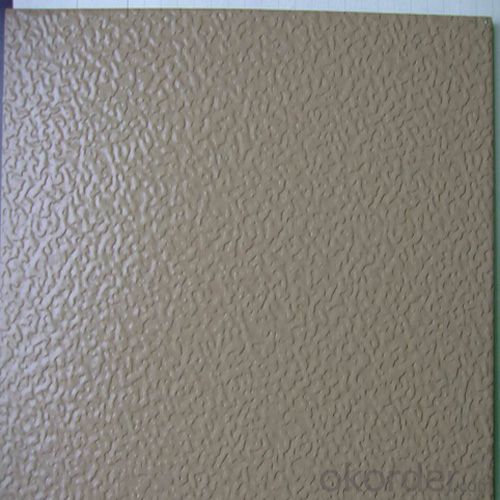

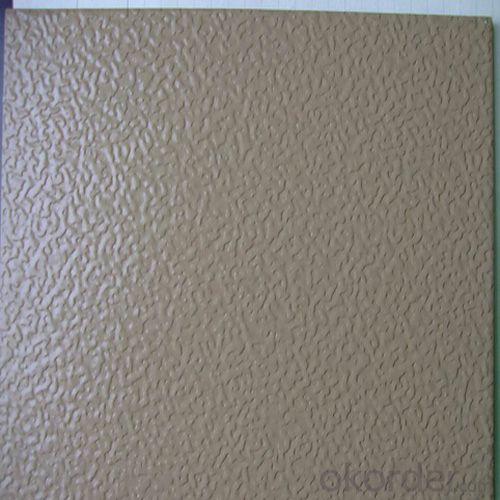

1.Structure of Aluminium Stucco Embossed Plate for Refrigeratory Description:

Aluminium Stucco Embossed Plates are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminium Stucco Embossed Plate for Refrigeratory:

Aluminum Alloy Grade: 1050 1060 1100 3003 5052

Temper: H12, H14, H18, H22, H24, H26

Thickness: 0.8mm~5.0mm

Thickness tolerance: +/-0.01-0.04mm

3. Aluminium Stucco Embossed Plate for Refrigeratory Images:

4. Aluminium Stucco Embossed Plate for Refrigeratory Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum plates be welded with stainless steel or iron nuts?

- In theory, yes, such as brazing.In fact, few people do that:Aluminum and steel systems do not form stable alloy remelting. Brazing is actually the use of third materials to link two original or dissimilar materials together. Unlike bonding, a stable alloy phase can be formed.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Certain applications may find aluminum sheets suitable for use in electrical bus bars. Aluminum possesses several properties that make it a viable choice for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in situations where weight reduction is crucial. Furthermore, aluminum exhibits good electrical conductivity, although it falls short of copper in terms of conductivity. Nevertheless, aluminum bus bars can still handle high electrical currents and are commonly employed in power distribution systems. However, one drawback of aluminum bus bars is their higher resistance compared to copper bus bars. Consequently, they have a tendency to generate more heat, particularly under heavy current loads. To address this issue, aluminum bus bars are often designed with larger cross-sectional areas to minimize resistance and dissipate heat more effectively. Another challenge associated with aluminum bus bars is their vulnerability to oxidation and corrosion. This concern can be tackled by applying protective coatings or utilizing alloys that offer superior corrosion resistance. Additionally, it is crucial to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In conclusion, aluminum sheets can serve as suitable materials for electrical bus bars, particularly in scenarios where weight reduction is a priority. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: what's the size of aluminum sheet circle?

- aluminum sheet circle's texture 1060, 3003 thickness 0.4-5.0mm, diameter 190-760mm.

- Q: Are aluminum sheets suitable for hydraulic applications?

- Indeed, aluminum sheets prove to be fitting for hydraulic applications. Being both lightweight and resistant to corrosion, aluminum serves as a remarkable option for hydraulic systems. Its commendable thermal conductivity aids in effectively dispersing heat produced during hydraulic operations. Furthermore, aluminum sheets can be effortlessly shaped and machined to fulfill precise design needs, rendering them adaptable for an array of hydraulic components including reservoirs, tanks, and piping systems. Nevertheless, it is crucial to bear in mind the pressure and temperature prerequisites of the hydraulic application, given that aluminum possesses inferior strength and melting point in comparison to metals like steel.

- Q: Can aluminum sheets be easily shaped or bent?

- Yes, aluminum sheets can be easily shaped or bent due to their malleability and low density.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation. Aluminum has good soundproofing properties due to its high density and ability to reflect sound waves. When used as a barrier or in combination with other sound-absorbing materials, aluminum sheets can effectively reduce noise transmission.

- Q: Are aluminum sheets suitable for chemical processing?

- Yes, aluminum sheets are suitable for chemical processing due to their excellent corrosion resistance, high thermal conductivity, and lightweight properties. They can be effectively used for various chemical applications such as containers, piping, and heat exchangers.

- Q: What does aluminum plate "1060-H24" mean?

- Each digit in the 1060-H24 stands for the following meanings:First, a number of Arabia 1 is representative of pure aluminum (aluminum is aluminum content above 99% aluminum, in addition to the beginning and start with 2-8 are 2### for copper and aluminum magnesium alloy, 3### aluminum manganese alloy, 4### alloy, 5### alloy and so on)

- Q: Are aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its lightweight, high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. It is used in aircraft structures, wings, fuselages, and other components to provide durability and fuel efficiency.

- Q: What are the different types of aluminum sheets?

- The different types of aluminum sheets include plain aluminum sheets, embossed aluminum sheets, perforated aluminum sheets, painted aluminum sheets, and brushed aluminum sheets.

Send your message to us

Aluminum Sheets Perforated Embossed Aluminum Stucco Plate for Refrigeratory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords