Aluminum Decorative Metal Sheets - Food Grade Coating Stucco Embossed Aluminum Freezer Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

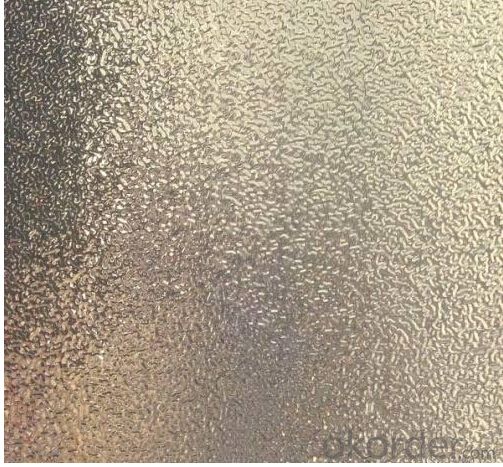

1.Structure of Food Grade Coating Stucco Embossed Aluminum Freezer Sheet Description:

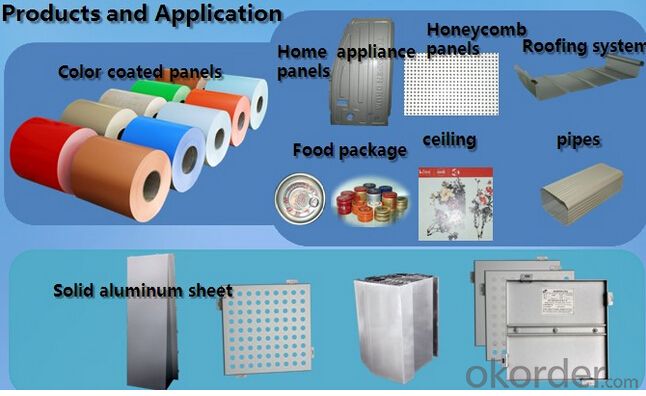

Food Grade Coating Stucco Embossed Aluminum Freezer Sheet is widely used in the strength requirements of the product. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Food Grade Coating Stucco Embossed Aluminum Freezer Sheet:

Aluminum Alloy: 1100 3003 3004 5052 5182

Temper: O-H112

Thickness: 0.15mm---1.5mm

Width: From 18mm---2000mm

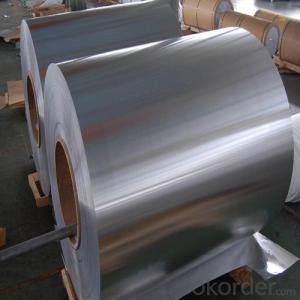

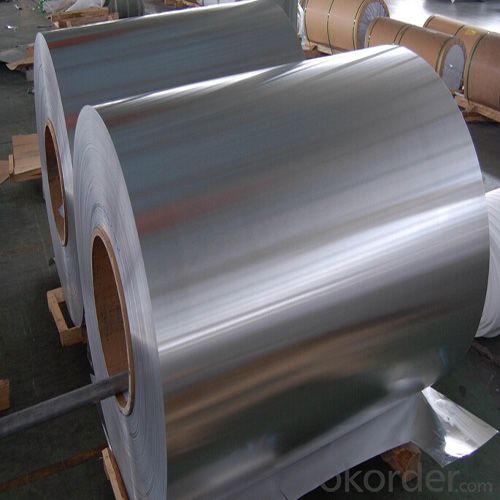

3. Food Grade Coating Stucco Embossed Aluminum Freezer Sheet Images:

4. Food Grade Coating Stucco Embossed Aluminum Freezer Sheet Specification:

ALLOY | SEPCIFICATION | TEMPER | |

THICKNESS | WIDTH | ||

1100, 1050,1060,1070 | 1.0-5.0 | 1000-2200 | H114,H112 |

3003,3004,3105 | 1.0-5.0 | 1000-2200 | H114,H112 |

5052,5005,5754,5083 | 1.0-5.0 | 1000-2200 | H114,H112 |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are the aluminum sheets suitable for aerospace applications?

- Indeed, aluminum sheets prove to be a suitable choice for aerospace applications. The aerospace industry widely embraces aluminum due to its exceptional strength-to-weight ratio, resistance against corrosion, and high thermal conductivity. These remarkable attributes render aluminum an ideal material for fabricating aircraft structures, such as fuselages, wings, and structural components. Moreover, aluminum can be effortlessly machined and shaped into intricate forms, enabling the production of lightweight and streamlined structures. Additionally, aluminum sheets can be easily joined using various techniques, including welding and riveting, ensuring the integrity of aerospace components. All in all, aluminum sheets are highly compatible with aerospace applications and have been extensively employed in the industry for numerous years.

- Q: Do 101 aluminum sheets have any specific fire resistance properties?

- Indeed, specific fire resistance properties are possessed by a total of 101 aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum can endure high temperatures before the onset of melting. Furthermore, due to its low combustion point, aluminum does not easily ignite. In the event of a fire, the aluminum sheets serve as a barrier that hinders the spread of flames. Furthermore, the burning of aluminum results in the formation of a protective oxide layer on its surface, which effectively impedes the advancement of the fire. Nevertheless, it is important to acknowledge that although aluminum exhibits fire-resistant characteristics, it is not entirely impervious to fire and can still suffer damage or deformation when subjected to intense heat.

- Q: This is kind of odd, but if a volcano erupted and the lava dripped into an aluminum can, would the can melt? Would the lava harden and cool in it?

- Temperature of lava - 700 degrees Celsius. Melting point of aluminum - 660 degrees Celsius. I'll let you figure out if the can would melt...

- Q: Can aluminum sheets be used for reflective purposes?

- Yes, aluminum sheets can be used for reflective purposes due to their high reflectivity and low absorption of light.

- Q: Aluminum or steel bike frame cost more???...which one cost the most usually???

- With climbs like this involved its just not practical. Granted, If I was touring, I would consider steel but it's a very different sort of riding (horses for courses eh?) and I would have to really go out of my way to find a steel frame. With time trials, the bikes do need to be stiff, strong and light(although more consideration is given to aerodynamics on a TT bike)Time in the saddle is irrelevent to a competitor who will often risk a right arm to win. But can I let you into an even bigger secret? The world of 'roadies' is one of snobbery, people with steel bikes are looked at as 'stalwarts of the old school' and it's akin to turning up at a race event with pedal straps,argyle socks and a rucksack full of luncheon meat sandwiches. Now do you understand where I'm coming from? My writing style is abrasive (people say I talk that way too!) and no offence to you was intended but you did mock the other guy. EDIT2: It seems some wires were crossed somewhere then? Hard to believe but I get carried away verbally too!! The best bet is to let it lie! To be honest with you, I have never ridden climbs this bad before, over this distance (106 miles)- I'm told It's a tough one and I am determined to complete before two certain riders(workmates!) - it's a matter of honour, you understand! Happy riding mate. .

- Q: Can aluminum sheets be used for elevator panels?

- Indeed, elevator panels can be made using aluminum sheets. Aluminum, renowned for its versatility and durability, finds extensive utility in construction and architectural undertakings, such as crafting elevator interiors. It possesses various merits, including its lightweight nature, resistance to corrosion, and effortless maintenance. Aluminum panels can be tailored to meet the precise design prerequisites of elevator interiors, and their aesthetic appeal and durability can be amplified by applying diverse surface treatments or coatings. Moreover, aluminum emerges as an environmentally-conscious choice for elevator panels due to its sustainability, as it can be readily recycled.

- Q: How to clean the aluminium oxide on the surface of aluminum? What kind of materials should we use to clean the thin aluminum sheet, and what's the concentration?

- you can answer sodium hydroxide solution, dilute acid is useless, aluminum's oxide film is very thick,as for concentration, aluminum will be passivating in concentrated sulfuric acid. if you are high school student,higher concentration is better, you can complete deoxidation by abrasive paper.

- Q: is there any kind of deoderant, other than those crystals that smell, that don't have aluminum in it?

- Green People's deodorant doesn't have aluminium or parabens; many people avoid these to be on the safe side. Please be aware though that 'deodorants/anti-perspirants cause breast cancer' is an urban myth. There is no evidence that this is the case and the email that did the rounds a while ago was a hoax.

- Q: What are the physical properties of aluminum sheets?

- Aluminum sheets possess several physical properties, including being lightweight, corrosion-resistant, and having a high strength-to-weight ratio. They are also ductile, meaning they can be easily shaped or formed without breaking. Additionally, aluminum sheets have excellent thermal and electrical conductivity, making them suitable for various applications in industries such as construction, aerospace, and automotive.

- Q: What are the mechanical properties of aluminum sheets?

- Aluminum sheets are highly sought after in various industries due to their unique mechanical properties. To begin with, they possess an exceptional strength-to-weight ratio, making them both lightweight and strong. This quality is particularly valuable in industries like aerospace and automotive, where reducing weight is crucial. Furthermore, aluminum sheets are highly malleable, allowing them to be easily shaped and formed into different sizes and configurations. This versatility makes them ideal for applications that require complex shapes, such as the manufacturing of cans, appliances, and architectural components. In addition, aluminum sheets have a high resistance to corrosion, thanks to the development of a thin, protective oxide layer on their surface. This durability makes them suitable for outdoor applications or environments with high moisture or chemical exposure. Moreover, aluminum sheets exhibit excellent thermal conductivity, enabling them to efficiently transfer heat. This property makes them widely used in heat exchangers, cooling systems, and other applications where effective heat dissipation is necessary. Lastly, aluminum sheets possess good electrical conductivity, allowing them to effectively conduct electricity. This makes them suitable for electrical enclosures, conductors, and other electrical applications. To summarize, the mechanical properties of aluminum sheets include a high strength-to-weight ratio, good formability, high corrosion resistance, excellent thermal conductivity, and good electrical conductivity. These properties make aluminum sheets the preferred choice for a wide range of applications across various industries.

Send your message to us

Aluminum Decorative Metal Sheets - Food Grade Coating Stucco Embossed Aluminum Freezer Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords