All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

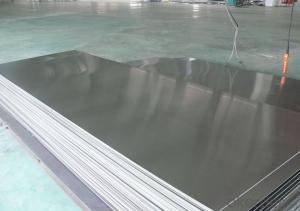

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

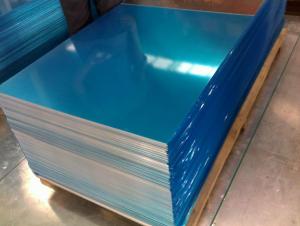

How do manufacturers ensure the adhesion and durability of coatings and finishes on aluminum sheets?

Manufacturers ensure the adhesion and durability of coatings and finishes on aluminum sheets through several methods. Firstly, they thoroughly clean and prepare the surface of the sheets by removing any contaminants or oxidation. This is usually done through processes like acid etching or sandblasting.

Next, manufacturers often apply a primer or pretreatment to the aluminum surface, which helps in promoting the adhesion of the coating. The primer acts as a bonding agent between the aluminum and the subsequent coating layer, enhancing its durability.

Furthermore, manufacturers may use advanced coating techniques such as electrostatic spraying or powder coating, which ensure an even and uniform application of the coating material. These methods maximize adhesion and minimize the risk of defects or uneven coverage.

To enhance durability, manufacturers may also bake or cure the coated aluminum sheets at specific temperatures and durations. This step helps in cross-linking the coating molecules and forming a strong bond with the aluminum surface, resulting in improved resistance to corrosion, weathering, and wear.

Overall, by employing these preparation, priming, application, and curing techniques, manufacturers can ensure excellent adhesion and long-lasting durability of coatings and finishes on aluminum sheets.

How are recycled aluminum sheets processed and reintroduced into the production cycle to minimize waste?

Recycled aluminum sheets are processed through a series of steps to minimize waste and reintroduce them into the production cycle. First, the sheets are collected and sorted based on their quality and composition. They are then cleaned to remove any contaminants. Next, the sheets are shredded into smaller pieces and melted in a furnace to form aluminum ingots or billets. These ingots are then rolled into thin sheets or used to produce various aluminum products. By recycling aluminum sheets, we reduce the need for extracting new raw materials, conserve energy, and minimize waste in the production cycle.

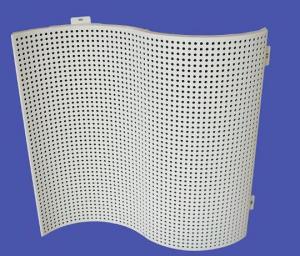

Can aluminum sheets be employed for noise reduction in architectural design?

Yes, aluminum sheets can be employed for noise reduction in architectural design. Aluminum sheets have excellent sound insulation properties and can effectively reduce noise transmission when used in walls, ceilings, or facades. Their lightweight yet sturdy nature allows for easy installation and can help create a quieter and more comfortable environment in buildings.

Wholesale Aluminum Sheets from supplier in Jamaica

We are a Aluminum Sheets supplier serving the Jamaica, mainly engaged in the sale, quotation, and technical support services of various Aluminum Sheets products in the Jamaica region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Sheets procurement services in the Jamaica. Not only do we have a wide range of Aluminum Sheets products, but after years of market development in the Jamaica, we can also provide valuable experience for your projects.