Sheets of Aluminum 4x8 - High Quality Aluminium Thick Sheet for Ships AA5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

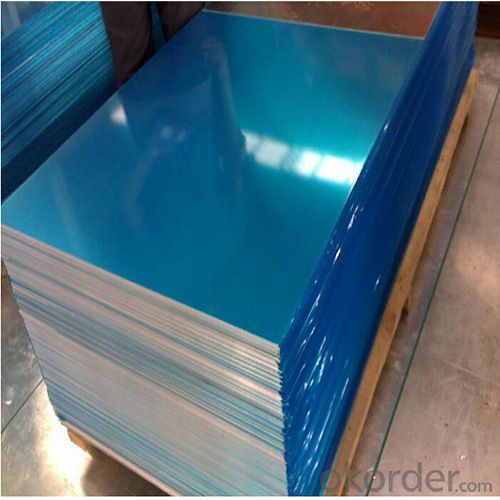

1.Structure of Aluminium Thick Sheet for Ships AA5052 Description:

Plastic Film Coated Aluminum Sheets are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminium Thick Sheet for Ships AA5052:

Be free from Oil Stain, Dent

Accurate tolerance

Nice mechanical property

High Quality

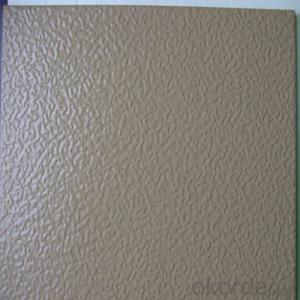

3. Aluminium Thick Sheet for Ships AA5052 Images:

4. Aluminium Thick Sheet for Ships AA5052 Specification:

Aluminum Alloy Grade | 5005 5052 5754 5083 |

| Pattern | H14 H16 H18 H24 H26 HO |

| Thickness | 0.8mm~200mm |

| MOQ | 8 tons |

| Packing | Waterproof film,kraft paper,wooden pallet and so on |

| Usage | LED Light Solar reflector plate Architectural appearance Indoor decoration: ceiling, curtain wall Furniture Elevator Index tag Case and bag Decoration in car Household appliances Boat and ship |

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process..

- Q: What kind of pattern aluminium plate has?

- Aluminum alloy decorative plate: aluminum alloy checkered plateThe aluminum alloy pattern board is made of the rust proof aluminum alloy and so on. It is made of special pattern, and the patterns are beautiful and elegant. It is not easy to wear and has good antiskid performance. It has strong corrosion resistance and is easy to flush. Different colors can be obtained by surface treatment. The pattern plate is smooth, the cutting size is accurate, easy to install. It is widely used in wall decoration and stairs and stair treads.

- Q: Can aluminum sheets be brushed or satin finished?

- Aluminum sheets have the capability to undergo brushing or satin finishing. Brushing or satin finishing is a method that involves the creation of a textured surface on the aluminum sheets. This can be accomplished by utilizing abrasive materials like sandpaper or wire brushes to generate a pattern of fine lines or scratches on the metal's surface. The purpose of this process is often to enhance the appearance of the aluminum sheets by providing them with a more matte and textured finish. Moreover, brushing or satin finishing can also serve to conceal minor imperfections or scratches on the surface of the aluminum sheets. In summary, the option to brush or satin finish aluminum sheets allows for flexibility in achieving desired aesthetics and surface textures in various applications.

- Q: How is the thickness of an aluminum sheet measured?

- The thickness of an aluminum sheet can be measured using various methods. One common technique is to use a micrometer or caliper, which are precision measuring tools. The micrometer is placed on one end of the sheet and slowly closed until it touches the other end, providing an accurate measurement of the thickness. This method is effective for measuring thin aluminum sheets. For thicker sheets, a thickness gauge can be used. It consists of a small handheld device with a probe that is pressed against the sheet's surface. The gauge then displays the thickness reading on a screen. This method is especially useful for measuring thicker sheets where a micrometer or caliper may not be suitable. Another way to measure the thickness of an aluminum sheet is by using an ultrasonic thickness gauge. This tool emits ultrasonic waves from a transducer, which are then reflected back from the sheet's surface. By calculating the time taken for the waves to travel and return, the gauge can determine the thickness of the sheet with high accuracy. This method is particularly effective for measuring the thickness of large or irregularly shaped aluminum sheets. In summary, the thickness of an aluminum sheet can be measured using various tools such as a micrometer, caliper, thickness gauge, or ultrasonic thickness gauge, depending on the thickness and size of the sheet.

- Q: Can aluminum sheet be used for heat sinks?

- Yes, aluminum sheet can be used for heat sinks. Aluminum is a common material used for heat sinks due to its excellent thermal conductivity properties. It is lightweight, affordable, and has good corrosion resistance. Aluminum sheet can be easily fabricated into various shapes and sizes, making it suitable for different heat sink designs. The flat and thin nature of aluminum sheet allows for efficient heat dissipation by increasing the surface area available for heat transfer. Additionally, aluminum can be easily machined or extruded to create fins, which further enhance the heat dissipation capability of the heat sink. Overall, aluminum sheet is a popular choice for heat sinks in various applications, including electronics, computers, LED lights, and automotive components.

- Q: How do you prevent fingerprints on aluminum sheets?

- One way to prevent fingerprints on aluminum sheets is by wearing gloves while handling them. Additionally, regularly cleaning the sheets with a gentle, non-abrasive cleaner can help remove any existing fingerprints and prevent new ones from forming.

- Q: What are the different types of patterns available for textured aluminum sheets?

- Textured aluminum sheets offer a variety of patterns, each with its own unique visual appeal and functionality. Some commonly used patterns include: 1. Diamond pattern: Also called tread plate or checker plate, this pattern features small raised diamonds on the sheet's surface. It provides excellent slip resistance, making it ideal for applications that require traction, such as ramps, stairs, or industrial flooring. 2. Stucco pattern: Resembling a textured wall or ceiling finish, the stucco pattern has raised ridges that create a rough and bumpy surface. It is often used for decorative purposes, adding depth and visual interest to architectural elements like walls, ceilings, or furniture. 3. Hammered pattern: Mimicking the appearance of a surface hammered by hand, the hammered pattern creates a dimpled and uneven texture. It is commonly used in architectural applications, such as wall panels, backsplashes, or decorative accents, to add a rustic and artistic touch. 4. Brushed pattern: The brushed pattern is achieved by brushing the surface of the aluminum sheet with a wire brush, creating long, uniform lines. It offers a sleek and modern appearance, making it popular for applications like kitchen appliances, signage, or interior design elements. 5. Perforated pattern: Unlike the previous patterns, the perforated pattern involves creating small holes across the aluminum sheet's surface. This pattern is often used in applications that require ventilation, sound absorption, or decorative effects, such as speaker grills, filters, or façades. These examples highlight the range of patterns available for textured aluminum sheets. The choice of pattern depends on the specific project requirements, including aesthetics, functionality, and durability.

- Q: Can aluminum sheets handle high temperatures?

- Certainly! High temperatures are well-tolerated by aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum proves itself suitable for various applications requiring elevated temperatures. Furthermore, aluminum possesses exceptional thermal conductivity, enabling rapid heat dissipation. This attribute renders aluminum sheets ideal for deployment in environments necessitating resistance against high temperatures, including engine components, heat exchangers, and oven linings. Nevertheless, it is crucial to take into account the specific alloy and thickness of the aluminum sheet, as different alloys may impose different temperature thresholds.

- Q: I am ultimately looking to have a bike that is good for both everday commuting and touring with panniers/racks long distance with camping. From what I've read on the internet steel frames are more forgiving and ride smoother. The guy at my local bike shop tells me aluminum frames have more flex and ride better. I don't know if he's just trying to make a sale (Giant dealer) or to trust him, unfortunately the staff there are all just racers not tourers. If you can recommend any brands/models to check out that'd be good. From my research thus far I am in love with Co Motion bikes, just not the price! I'm looking at $1000 max for a good touring bike. Thanks!

- looks like the Americano series are equipped with tandem wheelset. That's heavy duty touring. I believe he is trying to make a sale. If aluminum flexes, then the result will be a crack. If steel decide to fail, it bends from fatigue, aluminum just snaps when it fails. Steel gives you a much noticeable warning. So...steel bends. It flexes when you put a lot of stress, but when you are touring, it's not likely your going to go all out like racers do when they pursue. Steel will absorb more of the road vibrations and shock. You might want to try a different shop if all they do is pitch Giant brand. BTW Giant is THE world largest bicycle manufacturer. They build bikes for different companies besides their own. So you never know where or what brand your really riding. There are many touring bikes out, but if you go by manufacturers then it is only limited to a few by brands. There is more options when you want a racer. Remember when choosing a touring bike to choose one with a good wheelset. I like wheels with 36 spokes or more, they take the brunt of the weight (rack, pannier, other accessories).

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is a lightweight yet strong material that offers excellent corrosion resistance in marine environments. It is commonly used in the construction of various marine vessels, including boats, ships, and yachts. One of the main advantages of using aluminum sheets in marine vessel construction is their high strength-to-weight ratio. This allows for the construction of lighter vessels, which can result in improved fuel efficiency, increased speed, and better handling. Additionally, the lightweight nature of aluminum makes it easier to transport and maneuver during the construction process. Another key benefit of aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally forms a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Furthermore, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of complex hull structures and interior components. Aluminum also offers good thermal conductivity, which can help regulate temperature in the interior spaces of marine vessels. While aluminum sheets have many advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be taken to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight, high strength-to-weight ratio, corrosion resistance, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, proper precautions should be taken to prevent galvanic corrosion when aluminum is used alongside other metals.

Send your message to us

Sheets of Aluminum 4x8 - High Quality Aluminium Thick Sheet for Ships AA5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords