5052 125 Mill Finish Aluminum Sheet 5xxx Series Alloy for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet 5XXX Series Alloy for Automotive Body

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finish Aluminum Sheet 5XXX Series Alloy for Automotive Body

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet 5XXX Series Alloy for Automotive Body

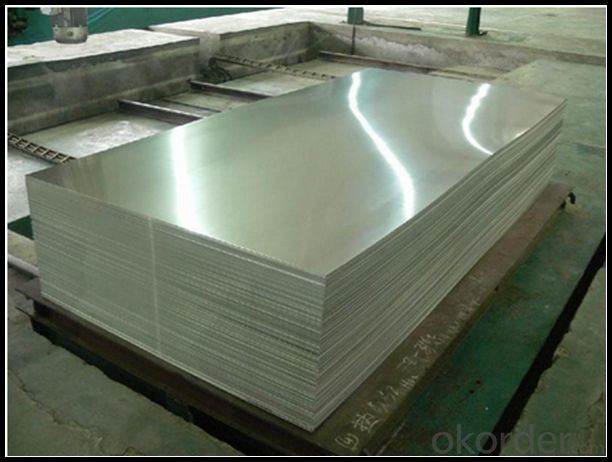

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

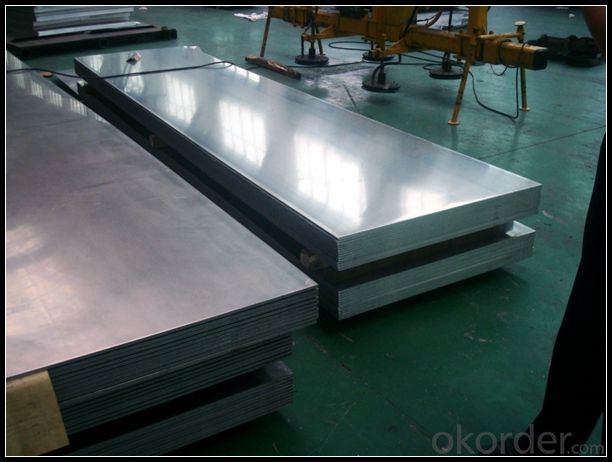

5. Image of Mill Finish Aluminum Sheet 5XXX Series Alloy for Automotive Body

6. Package and shipping of Embossed Aluminum Sheet AA1100 for Automotive Body

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can 101 aluminum sheets be used in the production of musical instruments?

- Yes, 101 aluminum sheets can be used in the production of musical instruments. Aluminum is a lightweight and durable metal that is commonly used in the manufacturing of various musical instruments. It offers good resonating properties and can produce a bright and clear sound. Additionally, aluminum is highly malleable, allowing it to be easily shaped and formed into different components of musical instruments such as bodies, frames, or keys. Therefore, 101 aluminum sheets can certainly be utilized in the production of musical instruments, contributing to their overall quality and performance.

- Q: I'm trying a new brownie recipe for the holidays this year. My experiences with baking brownies is never good. After I've taken them out of the oven and let them cool, I can never get them out of the pan without them falling apart on me! Can I bake brownies in the pan if it's lined with aluminum foil? I think that may make them easier to get out. Also, the new recipe I'm trying is actually a cheater recipe that starts with devils food cake mix. These are going to be gifts for friends and coworkers, and I just want perfectly squared, clean brownies! Any tips or ideas?

- New Classic Brownies (from Cookies and Brownies) 8 tbsp unsalted butter (1/2 cup) 4 oz unsweetened chocolate 1 1/4 cups sugar 1 tsp vanilla extract 1/4 tsp salt 2 eggs 1/2 cup all purpose flour 2/3 cup walnuts or pecans (optional) Preheat the oven to 400F and line and 8-inch square metal baking pan with foil. Melt the butter and the chocolate together, on top of a double boiler or in the microwave, stirring often until smooth. Stir in sugar, vanilla and salt. Add eggs one at a time, followed by flour. Stir until very smooth, about 1 minute. Add nuts, if using. Scrape batter into prepared pan and bake at 400F for 20 minutes. Meanwhile, prepare a water bath. Fill a large roasting pan with water and ice about 1 inch deep. When the brownies are done - and they will look a bit dry on top - take them immediately from the oven and place in the water bath. Add more ice to the water if necessary. Allow to cool completely in the bath before removing the pan and cutting the brownies. Store in an airtight container for up to 3 days. Makes 16.

- Q: What is the shear strength of aluminum sheets?

- The shear strength of aluminum sheets varies depending on the specific alloy and temper of the material. Generally, aluminum alloys have a lower shear strength compared to steels but higher than most other non-ferrous metals. The shear strength can range from approximately 30 to 60 MPa (MegaPascals) for common aluminum alloys used in sheet form. However, it is important to note that these values can vary depending on factors such as thickness, surface finish, manufacturing process, and any heat treatments applied to the aluminum sheets. Therefore, it is recommended to consult the specific material datasheet or contact the manufacturer for accurate and detailed information on the shear strength of a particular aluminum sheet.

- Q: What is the typical yield strength of aluminum sheets?

- The typical yield strength of aluminum sheets can vary depending on the grade and thickness of the sheet. However, on average, aluminum sheets have a yield strength ranging from 30 to 100 MPa (megapascals). It is important to note that this is a general range, and specific aluminum alloys may have higher or lower yield strengths. Additionally, the yield strength can also be influenced by factors such as heat treatment and processing conditions.

- Q: What are the various kinds of aluminum sheets utilized in the manufacturing of automobiles?

- <p>Aluminum sheets are widely used in automobile manufacturing due to their lightweight and strength. The different types include: 1. 5000 series aluminum sheets, known for their good formability and corrosion resistance, often used for body panels. 2. 6000 series aluminum sheets, which are strong and used for structural components. 3. 7000 series aluminum sheets, known for their high strength-to-weight ratio, used in safety-critical parts. 4. Aluminum alloy sheets, which combine the properties of aluminum with other elements for specific applications. 5. Aluminum clad sheets, which have a corrosion-resistant layer on the surface. These types are chosen based on the specific requirements of each automotive component.</p>

- Q: has aluminum sheet reacted with concentrated sulfuric acid?

- it can be regarded as no reaction, concentrated sulfuric acid will make aluminum's surface inactivation,and produce a layer of dense aluminium oxide film which will prevent further reaction.

- Q: Are the aluminum sheets suitable for manufacturing solar reflectors?

- Yes, aluminum sheets are suitable for manufacturing solar reflectors due to their high reflectivity, lightweight nature, and durability in outdoor conditions.

- Q: Calculate the mass in grams of Iodine (I2) that will react completely with 20.4 g of aluminum to form aluminum oxide (AlL3)

- actually the guy before me did it right but made a mistake at one point 0.07 mole is the # of moles of Al which needs to be changed to moles of product, and then back to find mole of iodide. once thats found then you can use the MW to change it to grams.

- Q: What specific tools or equipment are required when working with aluminum sheets?

- <p>When working with aluminum sheets, you'll need a few special tools and equipment. These include sheet metal shears for cutting, a metal file for smoothing edges, a metal straight edge for measuring and marking, and a vise for holding the sheet securely. For bending, a sheet metal brake is essential. Safety gear such as gloves and goggles are also crucial to protect against sharp edges and debris. Additionally, a T-square and a marker are needed for precise measurements and markings.</p>

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. Aluminum is a popular material choice for HVAC systems due to its various beneficial properties. Firstly, aluminum is lightweight yet strong, making it easy to handle and install in HVAC systems. Its low density also allows for cost-effective transportation and reduces the overall weight of the HVAC units. Secondly, aluminum has excellent corrosion resistance. HVAC systems often encounter moisture and condensation, especially in air conditioning units, and aluminum's resistance to corrosion ensures its durability and longevity in such environments. Additionally, aluminum sheets have good thermal conductivity, allowing for efficient heat transfer throughout the HVAC system. This property is particularly important in heating and cooling applications, as it helps to distribute the desired temperature effectively. Moreover, aluminum is a non-toxic material, making it safe for use in HVAC systems that circulate air throughout buildings. It does not release any harmful particles or gases into the air, ensuring the quality of indoor air. Lastly, aluminum is a highly recyclable material, making it environmentally friendly. The ability to recycle aluminum sheets reduces the carbon footprint associated with HVAC systems and aligns with sustainability goals. Considering all these advantages, aluminum sheets are indeed suitable for use in HVAC systems, providing an optimal balance of strength, corrosion resistance, thermal conductivity, safety, and environmental friendliness.

Send your message to us

5052 125 Mill Finish Aluminum Sheet 5xxx Series Alloy for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords