ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

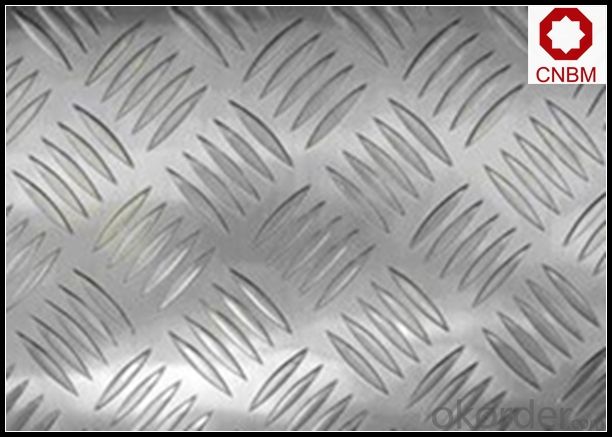

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

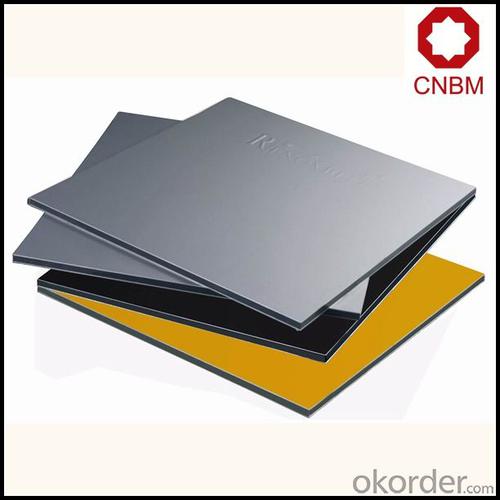

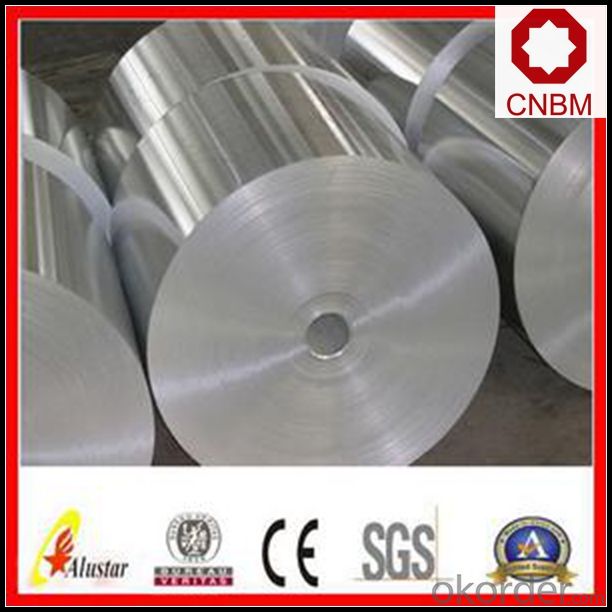

5. Image of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

6. Package and shipping of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I want to separate the copper and aluminum so I will get more at the scrap yard for my radiators any one know of an easy way to do this? Thanks

- I do not think its worth it. Radiators in whole ar going for around $1.28 per lb. For current pricing go to www.scrapmetalpricesandauctions.c...

- Q: How are aluminum coils protected from damage during transportation?

- To protect aluminum coils during transportation, a combination of packaging materials and handling precautions is utilized. Initially, the coils are wrapped with materials like stretch film or plastic wrap to prevent scratches and abrasions, thus maintaining the coil's surface integrity and preventing potential damage. Moreover, the coils are typically placed on sturdy wooden pallets or skids, providing a stable base for transportation. This reduces movement and shifting during transit, avoiding dents or deformations in the coils. Additionally, steel or plastic strapping is used to secure the coils, ensuring their stability and preventing unintended unwrapping or unrolling. The straps are tightly fastened around the coils and pallets, creating a secure bundle capable of withstanding jostling and vibrations during transportation. During loading and unloading, specialized equipment like forklifts or cranes is employed to handle the coils carefully, reducing the risk of dropping or mishandling that could result in significant damage. In summary, a combination of protective packaging materials, secure pallets, and careful handling procedures is employed to protect aluminum coils during transportation. These measures aim to preserve the coils' quality and structural integrity, ensuring they reach their destination in optimal condition.

- Q: My favorite deodorant contains aluminum. It smells really good and it works really well.My mom doesn't like me using it because it contains aluminum.So I got aluminum free. It doesn't smell at all (I can't seem to find fragrant aluminum free deodorant) and it doesn't work as well, for some reason.I want to keep using the one with aluminum, but will it be harmful to me in the future?

- i have tom deo. and it is totally safe, it is all organic stuff that you could like grow in your backyard. As apposed to chemical junk. kudoos to you for stopping with the anti-perspirants

- Q: The user is inquiring about the possibility of reusing their old aluminum coils or purchasing used ones.

- <p>Yes, you can reuse your old aluminum coils if they are still in good condition and meet the required specifications for your application. Reusing can be cost-effective and environmentally friendly. When buying used coils, ensure they are from a reputable source and have been properly inspected for any damage or wear that could affect performance. It's crucial to verify the coils' integrity and functionality before use to avoid any potential issues in your manufacturing or production process.</p>

- Q: wood aluminium windows?

- Vinyl looks MODERN and are in all the track homes. If you want you home to look cookie cutter choose the vinyl. If you have a nice home in an upscale neighborhood choose wood and any other other combo of wood and ?. If you are like the rest of us average shmos get the white vinyl

- Q: Can aluminum coils be used in electrical or electronic applications?

- Yes, aluminum coils can be used in electrical or electronic applications. Aluminum is a highly conductive material and has several advantages over other materials, such as copper, when it comes to coil applications. Aluminum coils are lightweight, which makes them suitable for applications where weight is a concern. They also have good thermal conductivity, allowing for efficient heat dissipation. Additionally, aluminum coils are corrosion-resistant, making them durable and suitable for outdoor or high-humidity environments. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so the design and dimensions of the coil need to be carefully considered to ensure optimal performance.

- Q: Can aluminum coils be used in the manufacturing of cans?

- Aluminum coils play a crucial role in the production of cans. They are commonly utilized to manufacture thin aluminum sheets, which are subsequently molded into cans. To achieve the desired thickness and width for can production, the coils undergo a series of steps, including rolling, annealing, and slitting. Once the aluminum sheets are prepared, they are cut into suitable sizes and shaped into the familiar cylindrical can form. Aluminum is a favored material for can manufacturing because of its lightweight, durable, and corrosion-resistant properties. Moreover, it serves as a protective barrier against light, oxygen, and moisture, thus ensuring the preservation of the contents' quality and shelf life. In summary, aluminum coils are an indispensable element in the can manufacturing process and play a significant role in the packaging industry.

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Yes, aluminum coils are generally more cost-effective compared to other materials like copper. There are several reasons for this. Firstly, aluminum is a more abundant metal than copper, which makes it cheaper to produce. This abundance also means that aluminum prices tend to be more stable and less prone to fluctuations in the market, further contributing to its cost-effectiveness. Secondly, aluminum coils have a lower density compared to copper coils, resulting in lighter weight units. This lighter weight not only reduces transportation and installation costs but also makes aluminum coils easier to handle and maneuver during the manufacturing process. Additionally, aluminum coils have excellent thermal conductivity properties, which means they can effectively transfer heat. This allows for more efficient cooling or heating systems, resulting in lower energy consumption and operating costs over time. Moreover, aluminum has a higher resistance to corrosion compared to copper, making it more durable and requiring less maintenance. This increased lifespan of aluminum coils reduces replacement and repair costs, further enhancing their cost-effectiveness. Lastly, aluminum coils are recyclable, and the recycling process requires significantly less energy compared to producing new aluminum. This aspect contributes to the overall sustainability and cost-effectiveness of aluminum coils. Overall, considering the lower production costs, lighter weight, superior thermal conductivity, increased durability, and recyclability, aluminum coils are indeed more cost-effective compared to other materials like copper.

- Q: Are aluminum coils suitable for architectural sunshades?

- Yes, aluminum coils are suitable for architectural sunshades. Aluminum is a popular material choice for sunshades due to its lightweight nature, durability, and corrosion resistance. Aluminum coils can be used to create various shapes and designs for sunshades, allowing for flexibility in architectural design. Additionally, aluminum can be easily fabricated and installed, making it a practical choice for architectural projects. Furthermore, aluminum has excellent thermal properties, allowing it to effectively reflect heat and reduce solar gain, which can help improve energy efficiency in buildings. Overall, aluminum coils are a suitable and versatile option for architectural sunshades.

- Q: What is the role of aluminum coils in the construction of railways?

- Aluminum coils are used in the construction of railways for various purposes, primarily for the manufacturing of overhead lines and electrical conductors. Due to their high conductivity, lightweight nature, and corrosion resistance, aluminum coils are ideal for transmitting electrical power and ensuring efficient and reliable railway operations. These coils are also utilized in the production of railway carriages and components, providing strength and durability while reducing overall weight, which ultimately improves fuel efficiency and lowers operating costs. Overall, aluminum coils play a crucial role in enhancing the performance, safety, and sustainability of railway systems.

Send your message to us

ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords