Green Aluminum Coil - Coated and Stucco Embossed Aluminium Coils Alloy 3003

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

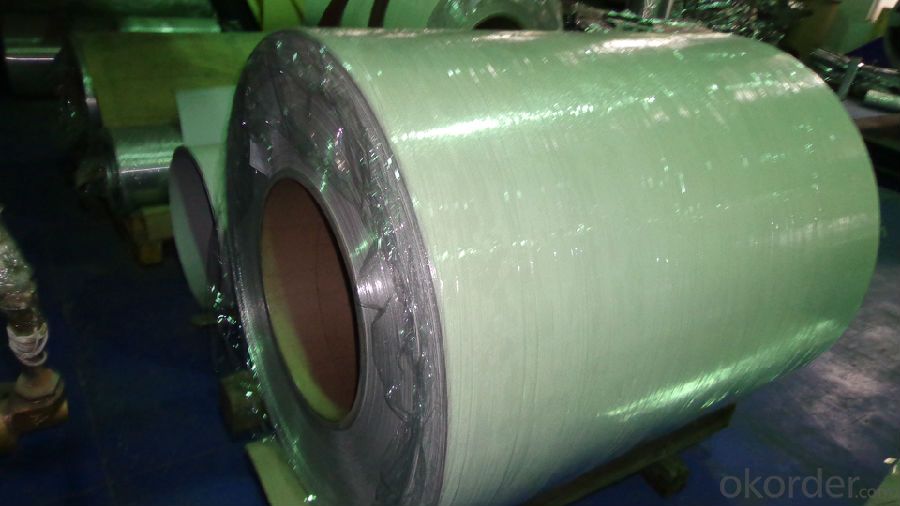

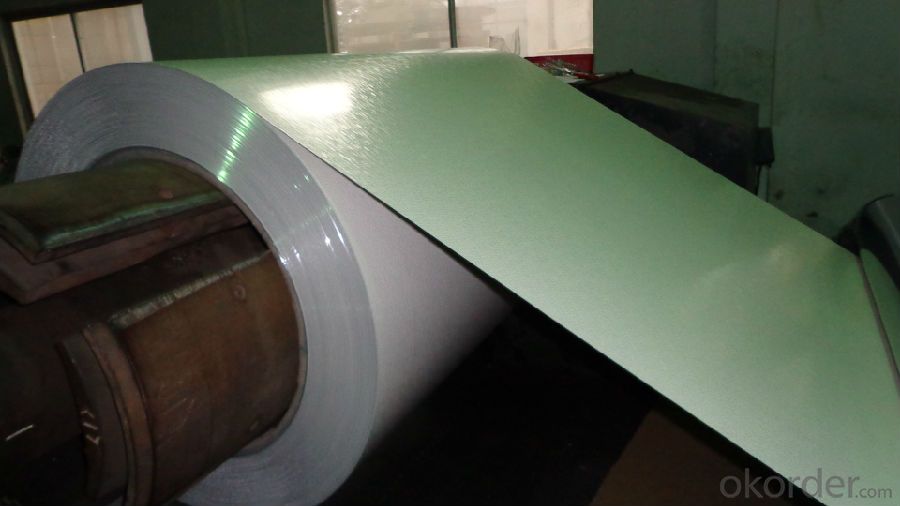

1.Structure of Coated and Stucco Embossed Aluminium Coils Alloy 3003

Alloy 3003, H44 is widely used in cold storages, refrigerators, ice-boxes, etc after being coated and stucco embossed.

We normally use 3003, H44 as base coils. Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of Coated and Stucco Embossed Aluminium Coils 3003

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. Coated and Stucco Embossed Aluminium Coils 3003 Images

4. Specification of Coated and Stucco Embossed Aluminium Coils 3003

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What is the mass of 3.45 moles of Aluminum sulfate?Can u explain how?

- Aluminum sulfate is Al2S3, so you got two atoms of aluminum and three of oxygen. Hence the molar mass of aluminum sulfate is: 2X16 (two times molar mass of oxygen) + 3X32 (three times molar mass of sulfur). Keep in mind that the molar mass of an elements equals its mass number. We have 128 grams per mole or 128 pounds per lb-mol. Since you have 3.45 moles of Al2S3 you just have to do 3.45 times 128 = 441.6 grams

- Q: To put aluminum heads on my car do i have to add other things or basically can i just get them and put them on

- Aluminum heads will warp the first time the engine accidentally overheats. Why would you go with aluminum?

- Q: Can aluminum coils be used for heat transfer applications?

- Indeed, heat transfer applications can utilize aluminum coils. The commendable thermal conductivity of aluminum renders it remarkably efficient in transferring heat. In multiple heat transfer applications like air conditioning systems, refrigeration units, and heat exchangers, aluminum coils are frequently employed. The lightweight nature of aluminum, coupled with its resistance to corrosion, further contributes to its widespread preference in these applications. Moreover, the malleability of aluminum coils allows for the facile shaping and forming, thereby facilitating efficient heat transfer even in intricate systems.

- Q: What are the standard tolerance levels for aluminum coils?

- The standard tolerance levels for aluminum coils can vary depending on the specific requirements and industry standards. However, common tolerance levels for aluminum coils typically range from +/- 0.003 to 0.020 inches for thickness, and +/- 0.005 to 0.100 inches for width. It is important to consult the appropriate industry standards and specifications to determine the specific tolerance levels needed for a particular application.

- Q: Can aluminum coils be used in automotive body panels?

- Automotive body panels can indeed utilize aluminum coils. Being both lightweight and corrosion-resistant, aluminum proves to be a suitable material for automotive purposes. The employment of aluminum coils in body panels yields numerous benefits, such as enhanced fuel efficiency owing to the reduced vehicle weight, improved handling and maneuverability, and increased durability. Moreover, aluminum boasts high recyclability, rendering it an environmentally conscious alternative for automotive production. Numerous automakers have already begun integrating aluminum coils into their vehicles, and this trend is anticipated to persist as the industry aims for lighter and more environmentally sustainable automobiles.

- Q: could you please help me find information of the element aluminum??? all the information i can get will be great... thanks very mucho.... who discovered? where can i find pictures of it?

- Aluminum is from team 3 and there for has 3 electrons in its outer shell and desires 5 to fill it. it rather is going to react with any factors from team 5 that want aluminum's 3 electrons.

- Q: What are the common surface treatments for aluminum coils in the construction industry?

- In the construction industry, aluminum coils are widely used due to their lightweight, durability, and corrosion resistance. To enhance their performance and aesthetic appeal, various surface treatments are applied to aluminum coils. Some of the common surface treatments for aluminum coils in the construction industry include: 1. Anodizing: Anodizing is a widely used surface treatment that involves creating an oxide layer on the aluminum surface. This process provides enhanced corrosion resistance, improves weather resistance, and allows for coloring options. 2. Powder coating: Powder coating is a popular surface treatment method where a dry powder is electrostatically applied to the aluminum coil and then cured under heat. This results in a durable, smooth, and attractive finish that is resistant to chipping, fading, and scratching. 3. PVDF coating: Polyvinylidene fluoride (PVDF) coating is a high-performance coating that provides excellent weather resistance and color retention. It is commonly used in architectural applications where long-term durability and aesthetic appeal are desired. 4. Paint coating: Traditional liquid paint coatings are also applied to aluminum coils, providing a wide range of color options and finishes. Paint coatings offer good corrosion resistance and can be customized to meet specific design requirements. 5. Brushed finish: Brushing the aluminum surface creates a textured finish that gives a unique appearance to the coils. The brushed finish can be achieved using mechanical or chemical processes, enhancing the aesthetic appeal of the aluminum coils. 6. Laminating: Laminating is a surface treatment method where a layer of protective film or laminate is applied to the aluminum coil. This protects the coil from scratches, stains, and other damage during handling, transportation, and installation. These surface treatments not only enhance the durability and performance of aluminum coils but also provide options for customization, allowing architects and designers to achieve their desired aesthetics while ensuring long-lasting performance in construction applications.

- Q: Can aluminum coils be used in heat exchangers?

- Yes, aluminum coils can be used in heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity and corrosion resistance. The high thermal conductivity of aluminum allows for efficient heat transfer, making it an ideal material for heat exchangers. Additionally, aluminum's corrosion resistance ensures that the coils will remain durable and functional even in harsh environments.

- Q: This question asks for the various uses of aluminum coil within the construction industry.

- <p>Aluminum coil has several applications in construction due to its lightweight, durability, and resistance to corrosion. It is commonly used in roofing and siding materials for both residential and commercial buildings. Aluminum coil is also utilized in the manufacturing of window frames and doors due to its strength and ability to withstand harsh weather conditions. Furthermore, it is used in the production of heat exchangers and HVAC systems because of its thermal conductivity. Additionally, aluminum coil is employed in the construction of scaffolding and temporary structures due to its ease of handling and high strength-to-weight ratio. It also finds use in the fabrication of electrical conduits and cable trays because of its electrical conductivity and resistance to moisture.</p>

- Q: ... of aluminum atoms?(mole = 6.022x10^23)

- WHEN IM OUT ON THE SEA WITH ME CREW I LIKE TO THINK THAT PERHAPSY WE CAN LOOT A BARGE FULL 'O THAT WONDROUS MATERIAL YE CALL ALUMINUM AS FER MOLES, THEY CAN BE QUITE THE PESTS AROUND YER GARDEN AND WHAT-NOT

Send your message to us

Green Aluminum Coil - Coated and Stucco Embossed Aluminium Coils Alloy 3003

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords