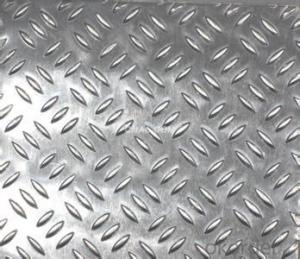

China Aluminum Coil Price AA 3003 Stucco Embossed Aluminium Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

supply Mill-finished / coated aluminum sheet/ coil:

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

- Q: Can aluminum coils be used for electrical transmission lines?

- Yes, aluminum coils can be and are commonly used for electrical transmission lines. Aluminum has several advantages that make it a suitable choice for transmission lines. First, aluminum is a lightweight material, which makes it easier and more cost-effective to transport and install. Second, aluminum is a good conductor of electricity, with similar conductivity to copper. Third, aluminum is less expensive than copper, making it a more economical option for long-distance transmission lines. However, there are some challenges associated with using aluminum coils in transmission lines. Aluminum has a lower tensile strength compared to copper, which means that it is more prone to sagging over long distances. Additionally, aluminum has a higher thermal expansion coefficient than copper, which can cause issues with thermal expansion and contraction. Despite these challenges, proper design and engineering can ensure that aluminum coils are used effectively and efficiently in electrical transmission lines.

- Q: What is the thickness range of aluminum coils?

- The thickness range of aluminum coils can vary depending on the specific application and industry. However, typically, the thickness range for aluminum coils is between 0.006 to 0.25 inches (0.15 to 6.35 mm). This range allows for a wide variety of uses, from thin and lightweight applications such as packaging materials or electrical components, to thicker coils used in construction or automotive industries. It's important to note that these are general ranges and the specific thickness requirements may vary based on the intended use and customer specifications.

- Q: What are the common recycling methods for aluminum coils?

- The common recycling methods for aluminum coils include sorting them based on their alloy composition, melting them down to remove any impurities, and then reusing the molten aluminum to make new coils or other aluminum products.

- Q: What are the different coil transportation options for aluminum coils?

- There are multiple transportation options available for aluminum coils, each offering their own advantages and suitability depending on various factors. These include: 1. Utilizing flatbed trucks: Commonly employed for aluminum coil transportation, flatbed trucks feature an open top and a flat, open trailer bed. To ensure secure transportation, the coils are firmly strapped or banded onto the bed, minimizing any potential movement. 2. Employing coil racks: Specifically designed for carrying aluminum coils, coil racks are specialized transportation equipment typically made of steel. These racks are placed within trucks or trailers, enabling the coils to be stacked and held in place by dividers, ensuring no shifting or damage occurs. 3. Opting for coil trailers: Specifically created for the transportation of aluminum coils, coil trailers possess a unique coil cradle system designed to securely hold the coils during transit. These cradles are adjustable, accommodating various coil sizes and preventing any potential movement or harm. 4. Considering container shipping: Another alternative for aluminum coil transportation involves the use of shipping containers. By loading the coils into the containers and securing them with straps or bracing, this option is frequently utilized for international transportation due to the ease of loading containers onto ships or trains. 5. Selecting rail transport: Rail transport presents an additional option for aluminum coil transportation, particularly for long-distance journeys. Specialized rail cars, known as coil cars, incorporate cradles or racks to securely hold the coils throughout the transit. This method is often chosen for its cost-effectiveness and efficiency. Ultimately, the selection of a suitable coil transportation option is dependent on factors such as distance, cost, and the specific requirements of the coils being transported.

- Q: The general roll also 5,6t appearance, specific to your own weigh, length, weight = / (width * thickness * density)

- The general roll also 5,6t appearance, specific to your own weigh, length, weight = / (width * thickness * density)

- Q: This question asks about the impact of aluminum coils on cooking equipment, including their role in heat distribution and potential benefits or drawbacks.

- <p>Aluminum coils in cooking equipment play a significant role in heat distribution and retention. They are known for their excellent thermal conductivity, which allows for even heat distribution across the cooking surface, reducing hot spots and ensuring consistent cooking results. Aluminum's lightweight and malleability also make it easy to shape into various forms, fitting different types of cookware. However, aluminum can react with acidic foods, potentially altering the taste or releasing small amounts of aluminum into the food, which some studies suggest could have health implications. Additionally, aluminum cookware requires careful handling to avoid scratches that can compromise its performance and appearance.</p>

- Q: Can aluminum coils be used in heat exchangers?

- Yes, aluminum coils can be used in heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity and corrosion resistance. The high thermal conductivity of aluminum allows for efficient heat transfer, making it an ideal material for heat exchangers. Additionally, aluminum's corrosion resistance ensures that the coils will remain durable and functional even in harsh environments.

- Q: hello, i'm doing a school project on aluminium and i'm a little stumped. what elements bond well with aluminium and why? thanks alot!

- Yes it will be a covalent bond. The simplest compound will be CH4 where each of the electron from the four H will be shared with one each from C to provide 4 covalent bonds.

- Q: Can a rolling machine be utilized to transform aluminum coils into flat sheets?

- <p>Yes, you can use a rolling machine to roll aluminum coils into sheets. Rolling machines are specifically designed to apply pressure and reduce the thickness of metal coils, such as aluminum, into thinner, flatter sheets. The process involves passing the aluminum coil through the rolling mill, where it is compressed between rollers. This process can be repeated to achieve the desired thickness and flatness of the aluminum sheet. It's important to ensure the rolling machine is suitable for aluminum and that the appropriate settings are used to avoid damaging the material or the machine.</p>

- Q: Can aluminum coils be used in the manufacturing of window frames?

- Window frames can indeed be manufactured using aluminum coils. Aluminum is a widely favored material for producing window frames because of its multitude of benefits. It is lightweight, long-lasting, and has a natural resistance to rust and corrosion, making it applicable for both indoor and outdoor usage. In the extrusion process, which is commonly employed, aluminum coils are heated and pushed through a die to attain the desired shape and size of the window frame. This method provides manufacturers with the flexibility to create window frames in diverse styles and configurations. Moreover, aluminum is highly recyclable, rendering it an environmentally conscious option for window frame production.

Send your message to us

China Aluminum Coil Price AA 3003 Stucco Embossed Aluminium Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords