China Pe Coated Aluminum Coil Stock for Aluminum Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil Stock used for Aluminum Foil

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Aluminum Coil Stock used for Aluminum Foil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coil Stock used for Aluminum Foil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

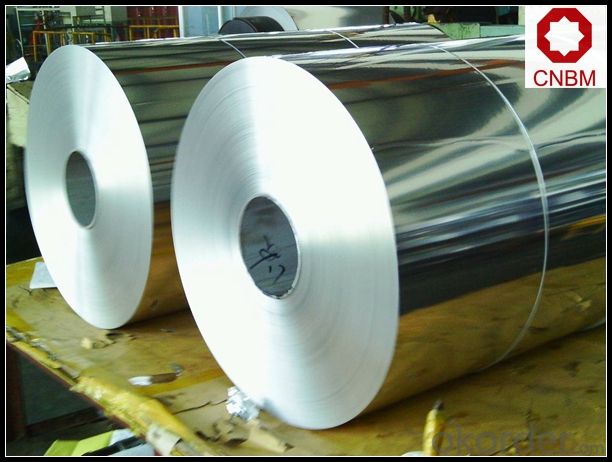

5. Image of Aluminum Coil Stock used for Aluminum Foil

6. Package and shipping of Aluminum Coil Stock used for Aluminum Foil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ of

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in the production of electronic devices?

- Yes, aluminum coils can be used in the production of electronic devices. Aluminum is a versatile and widely used material in various industries, including electronics. It possesses excellent electrical conductivity and thermal conductivity, making it suitable for use in electronic components such as coils and inductors. Aluminum coils are commonly used in power transformers, motors, generators, and other electronic devices where the transfer of electrical energy is necessary. Additionally, aluminum is lightweight, durable, and cost-effective, making it an attractive choice for manufacturers. However, it is important to note that the specific application and requirements of the electronic device will determine the suitability of aluminum coils.

- Q: How do aluminum coils compare to brass coils in terms of corrosion resistance?

- Aluminum coils generally offer better corrosion resistance compared to brass coils. This is primarily due to aluminum's natural oxide layer that forms on its surface, providing a protective barrier against corrosion. This oxide layer acts as a shield, preventing moisture and other corrosive elements from reaching the underlying metal. In contrast, brass coils are composed of a combination of copper and zinc, which are more susceptible to oxidation and corrosion. While brass coils may also develop a protective patina over time, it is not as effective as the oxide layer on aluminum coils. Therefore, aluminum coils are often preferred in applications where corrosion resistance is critical, such as in marine or coastal environments.

- Q: Are aluminum coils resistant to chemicals?

- Generally, chemicals do not pose a problem for aluminum coils due to their inherent resistance. This is because aluminum naturally develops a protective oxide layer on its surface, which shields it from various chemicals. Consequently, the oxide layer effectively prevents corrosion and deterioration of the aluminum coils when they come into contact with different substances. Nevertheless, it is worth mentioning that certain chemicals, particularly potent acids or alkalis, can still harm aluminum. In such instances, applying additional protective coatings or treatments becomes essential to strengthen the chemical resistance of the aluminum coils.

- Q: Are aluminum coils suitable for electrical insulation applications?

- No, aluminum coils are not suitable for electrical insulation applications. Aluminum is a highly conductive material, meaning it allows the flow of electricity. In electrical applications, insulation is required to prevent the flow of electricity and protect against short circuits or electrical shocks. Therefore, materials with low electrical conductivity, such as plastics, rubber, or fiberglass, are commonly used for electrical insulation purposes.

- Q: This question asks for the method to calculate the weight of an aluminum coil given its size.

- <p>To calculate the weight of an aluminum coil, you need to know its dimensions and the density of aluminum. The formula to calculate the weight is: Weight = Volume 脳 Density. First, determine the volume of the coil by multiplying its length (L), width (W), and thickness (T): Volume = L 脳 W 脳 T. The density of aluminum is approximately 2.7 grams per cubic centimeter (g/cm鲁). Convert the volume to cubic centimeters if it's not already. Then, multiply the volume by the density to get the weight in grams. To convert grams to kilograms, divide by 1000. This will give you the weight of the aluminum coil.</p>

- Q: Are aluminum coils resistant to corrosion?

- Yes, aluminum coils are highly resistant to corrosion due to the natural oxide layer that forms on their surface, protecting them from environmental factors.

- Q: What are the different hardness levels of aluminum coils?

- Aluminum coils come in various hardness levels, which are determined by the alloy and tempering process used in their manufacturing. The most common hardness levels for aluminum coils are as follows: 1. Soft (O temper): This state represents the utmost malleability and ductility of aluminum coils. It allows for extensive shaping and bending, making it suitable for applications that require such flexibility. 2. Quarter Hard (H12 temper): In this hardness level, aluminum coils have undergone a slight cold-working process to enhance their strength and stiffness. Although they are less malleable than soft coils, they still possess good formability. 3. Half Hard (H14 temper): Coils in this hardness level have undergone a moderate cold-working process, resulting in increased strength and stiffness. They are less formable than quarter-hard coils but are well-suited for applications requiring higher strength. 4. Three Quarter Hard (H16 temper): Aluminum coils in this hardness level have undergone a more intensive cold-working process, making them even stronger and less formable than half-hard coils. They are appropriate for applications that demand high strength and minimal deformation. 5. Full Hard (H18 temper): Coils in this hardness level have undergone the most extensive cold-working process, resulting in maximum strength and minimal formability. They are commonly employed in applications that prioritize high structural integrity and resistance to deformation. It is important to acknowledge that the specific hardness levels available for aluminum coils may vary based on the alloy and manufacturer. Moreover, different industries and applications may have specific requirements for hardness levels, so it is crucial to select the appropriate hardness level based on the intended use of the aluminum coils.

- Q: Is it possible to use aluminum coils in the creation of toys or games for children?

- <p>Yes, aluminum coils can be used to make toys or games for children, but safety considerations must be taken into account. Aluminum is a lightweight, durable, and non-toxic material, making it suitable for various applications, including children's toys. However, it's crucial to ensure that any aluminum used in toys is properly treated to prevent sharp edges or small parts that could pose a choking hazard. Additionally, the toys or games should be designed and manufactured to meet safety standards and regulations to protect children from potential harm.</p>

- Q: Can aluminum coils be used for electronic enclosures?

- Yes, aluminum coils can be used for electronic enclosures. Aluminum is a commonly used material for enclosures due to its lightweight, durability, and excellent electrical conductivity. Additionally, aluminum coils can be easily formed and shaped to fit specific electronic components, making them a suitable choice for electronic enclosures.

- Q: What is the role of aluminum coils in the construction of aircraft?

- The significance and versatility of aluminum coils in aircraft construction cannot be overstated. Aluminum, with its exceptional properties like lightweightness, durability, and resistance to corrosion, is the preferred material for manufacturing aircraft. In particular, aluminum coils find extensive use in various aircraft components such as the fuselage, wings, and structural elements. One of the primary functions of aluminum coils is to impart structural strength while keeping the aircraft lightweight. By incorporating aluminum coils, aircraft manufacturers can effectively reduce the overall weight of the aircraft, leading to improved fuel efficiency and increased payload capacity. This holds immense importance in aviation, where even the slightest reduction in weight can have a substantial impact on performance and operational costs. Furthermore, aluminum coils play a pivotal role in enhancing the aerodynamic design of the aircraft. These coils are employed to shape the wings and other aerodynamic surfaces, enabling superior airflow and decreased drag. The flexibility of aluminum coils empowers engineers to create intricate, curved shapes that optimize the aircraft's aerodynamic performance, resulting in enhanced maneuverability and reduced fuel consumption. Another critical aspect of aluminum coils in aircraft construction is their ability to resist corrosion. Aluminum naturally forms a protective oxide layer when exposed to air, rendering it highly resistant to corrosion. This property proves indispensable in ensuring the aircraft's longevity and structural integrity, especially when subjected to harsh environmental conditions like high altitudes or coastal regions. Moreover, aluminum coils find application in the manufacturing of heat exchangers, crucial components of the aircraft's cooling and ventilation systems. These coils efficiently transfer heat either to or from the air, depending on the requirements of the system, enabling effective temperature control within the aircraft's cabin and engine compartments. In conclusion, the role of aluminum coils in aircraft construction is indispensible. They provide structural strength, contribute to aerodynamic efficiency, offer corrosion resistance, and facilitate efficient heat exchange. The utilization of aluminum coils enables the development of high-performance, reliable, and fuel-efficient aircraft that are essential for modern aviation.

Send your message to us

China Pe Coated Aluminum Coil Stock for Aluminum Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords