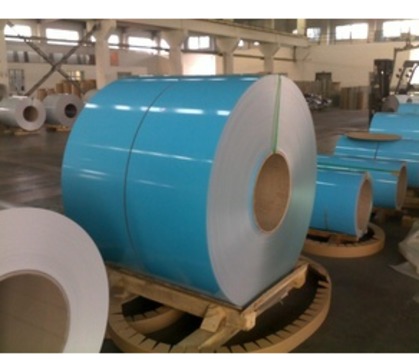

Aluminum Mill Coil - Prepainted Colorful Aluminum Coil and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011,etc

Temper:H14/16/18/22/24/32,HO etc.

Thickness:0.2mm—100mm

Width:100mm—2300mm (Can be slitted)

Inner Diameter: 508MM

CoilWeight:500kg-3000kg(Max.)

Application: Foil stock, Circles, Roofing, Canstock, Marine plate,Anti-sliperypurpose in vehicles, packing and appliance.

Specifications

aluminium coil for transformer winding with round edges and paper interleaf. ALUMINIUM COIL FOR TRANSFORMER WINDING

ALLOY | TEMPER | SPECIFICATION (MM) | |||

THICKNESS | I.D | O.D | WIDTH | ||

1050, 1050A 1060,1070 1070A,1350 |

O | 0.08---0.20 | 150, 300, 400 | 700--- --980 | 16.0--- ---1500.0 |

>0.20--1.50 | 150,205,300,350,400,500 | ||||

>1.50--3.00 | 300, 400, 500, 600 | ||||

Chemical Composition and Mechanical Properties

CHEMICAL COMPOSITION (Max) | |||||||||

Si | Fe | Cu | Mn | Gallium | Cr | Boron | Zinc | Ti+Van | |

0.10 | 0.40 | 0.05 | 0.01 | 0.03 | 0.01 | 0.05 | 0.05 | 0.02 | |

| |||||||||

UTS (Mpa) | ELONGATION

| At temperature of 20 deg. c | |||||||

RESISTIVITY Ω·mm²/M, max | CONDUCTIVITY%IACS, min | ||||||||

59--135 | 20% Min | 0.028035 | 61.5 | ||||||

WE HEREBY VERIFIED THAT THE GOODS ARE PRODUCED BY CNBM, WHICH HAS PASSED THE CERTIFICATION OF QUALITY SYSTEM FOR ISO9001.

- Q: what is aircraft grade aluminum?

- Aluminum is never used in it's pure form. It is always used as an alloy - in combination with other metals and substances. The phrase aircraft grade aluminum is a bit misleading because there are a large number of different grades of aluminum used on aircraft - some of them aren't very special at all, but some of the grades are highly specialized, down to the micro-structure of the metal. Different grades of aluminum contain different quantities of other substances may have been forged or wrought in different types of processes. Typically high performance military aircraft will utilize very grade materials. The common characteristics of high grade aluminum alloys are it's ability to withstand heat and fracturing they are also extremely light. When people advertise products like keys made from aircraft grade aluminum it makes me laugh - because it's most likely to be the same grade aluminum they use to make tray stands, certainly not the same grade they use for structural components! Hope this helps!

- Q: What are the advantages of using aluminum coils over other materials?

- There are several advantages of using aluminum coils over other materials. Firstly, aluminum is a lightweight material, making it easier to handle and transport. This lightweight nature also makes it more cost-effective as it requires less energy to manufacture and install. Secondly, aluminum has a high level of corrosion resistance. It does not rust, even when exposed to harsh environmental conditions, making it suitable for outdoor applications. This durability ensures a longer lifespan and reduces maintenance costs in the long run. Additionally, aluminum coils provide excellent heat transfer properties. They have a high thermal conductivity, allowing for efficient heat exchange. This makes them ideal for applications such as heating, ventilation, and air conditioning systems, where effective heat transfer is crucial. Moreover, aluminum is a highly recyclable material. It can be recycled repeatedly without losing its quality or performance. This not only reduces waste and contributes to environmental sustainability but also lowers production costs. Lastly, aluminum coils offer versatility in terms of design and customization. They can be easily formed, shaped, and coated to meet specific requirements. This flexibility allows for a wide range of applications in various industries, from automotive and construction to electronics and aerospace. Overall, the advantages of using aluminum coils, including its lightweight nature, corrosion resistance, heat transfer properties, recyclability, and versatility, make it a preferred choice over other materials.

- Q: Can aluminum coils be used in explosive environments?

- No, aluminum coils should not be used in explosive environments. Aluminum is a highly flammable metal, and when exposed to certain conditions, it can ignite and contribute to the spread and intensity of a fire. In explosive environments, such as those containing gases, vapors, or dust particles, the risk of fire or explosion is already heightened. Therefore, it is essential to avoid using aluminum coils in such environments to prevent potential ignition sources and ensure the safety of the surroundings. Instead, materials with higher resistance to heat and fire should be utilized in these hazardous settings.

- Q: What are the typical mechanical properties of aluminum coils?

- The mechanical properties of aluminum coils may differ depending on the specific alloy and temper of the material. However, aluminum coils typically possess the following mechanical properties: 1. Tensile strength: Aluminum coils generally demonstrate a high tensile strength, which refers to the maximum amount of tensile stress a material can endure before breaking. This property is crucial for applications that require the material to withstand heavy loads or stress. 2. Yield strength: Yield strength represents the stress threshold that a material can bear without undergoing permanent deformation. Aluminum coils typically possess a relatively high yield strength, enabling them to maintain their shape and structural integrity under normal operating conditions. 3. Elongation: Elongation refers to the extent to which a material can stretch or deform before fracturing. Aluminum coils usually exhibit a relatively high elongation, making them suitable for applications that involve forming or bending without breaking. 4. Hardness: The hardness of aluminum coils may vary depending on the alloy and temper. Aluminum alloys can undergo heat treatment to enhance their hardness, rendering them more suitable for applications that demand wear resistance or the ability to withstand harsh environments. 5. Fatigue strength: Fatigue strength denotes a material's capacity to resist the formation and growth of cracks under cyclic loading conditions. Aluminum coils generally exhibit good fatigue strength, making them suitable for applications subjected to repeated or fluctuating loads. It is important to note that these properties can vary depending on the specific alloy, temper, and processing conditions of the aluminum coils. Therefore, it is advisable to refer to the material specifications or contact the manufacturer for more precise and detailed information regarding the mechanical properties of specific aluminum coils.

- Q: What are the common methods of joining aluminum coils together?

- Common methods of joining aluminum coils together include welding, soldering, adhesive bonding, and mechanical fastening. Welding is a popular method that uses heat to melt the aluminum and join the coils together. Soldering involves using a lower melting point filler metal to bond the coils. Adhesive bonding uses adhesives or glues to create a strong bond between the coils. Mechanical fastening involves using screws, bolts, or other mechanical devices to hold the coils together.

- Q: Are aluminum coils suitable for electrical insulation applications?

- No, aluminum coils are not suitable for electrical insulation applications. Aluminum is a highly conductive material, meaning it allows the flow of electricity. In electrical applications, insulation is required to prevent the flow of electricity and protect against short circuits or electrical shocks. Therefore, materials with low electrical conductivity, such as plastics, rubber, or fiberglass, are commonly used for electrical insulation purposes.

- Q: Can aluminum coils be used in electrical cables?

- Yes, aluminum coils can be used in electrical cables. Aluminum is a commonly used material for electrical conductors due to its excellent electrical conductivity and relatively low cost compared to copper. It is especially used in power transmission and distribution cables where long-distance transmission is required. Aluminum coils are often used in overhead power lines and underground cables. However, it is important to note that aluminum has a lower tensile strength than copper, so the cables need to be properly designed and manufactured to ensure adequate mechanical strength. Additionally, aluminum conductors require larger cross-sectional areas compared to copper to achieve the same electrical performance, which can result in slightly larger cable sizes.

- Q: Is it possible to use a metal detector to locate an aluminum coil?

- <p>Yes, you can use a metal detector to detect aluminum coils. Metal detectors are designed to detect various types of metal, including aluminum. While they are often used for detecting ferrous metals like iron, they can also pick up non-ferrous metals such as aluminum. The effectiveness of detecting aluminum may vary depending on the type of metal detector and its sensitivity settings. Ground conditions and the size and composition of the aluminum coil can also affect detection. It's important to adjust the metal detector to the appropriate settings for detecting non-ferrous metals to increase the chances of successful detection.</p>

- Q: How are aluminum coils used in packaging?

- Aluminum coils are commonly used in packaging as they can be easily molded into different shapes and sizes. They are used to create various packaging products such as cans, containers, and foils. The coils are converted into sheets or strips, which are then formed into the desired packaging structures through processes like rolling, cutting, and shaping. The lightweight and corrosion-resistant nature of aluminum make it an ideal choice for packaging applications, ensuring the protection and preservation of various products.

- Q: Is it possible to use a welding torch for joining steel coils?

- <p>Yes, you can use a welding torch to weld steel coils together. However, it's important to choose the right type of welding process suitable for the specific steel grade and the desired strength of the joint. Common methods include gas metal arc welding (GMAW), shielded metal arc welding (SMAW), and flux-cored arc welding (FCAW). Ensure you follow safety protocols, use appropriate protective gear, and have a good understanding of the welding process to achieve strong, reliable welds.</p>

Send your message to us

Aluminum Mill Coil - Prepainted Colorful Aluminum Coil and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords