All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

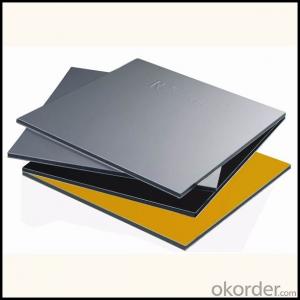

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of aluminum coils in the production of aluminum gutters and downspouts?

The role of aluminum coils in the production of aluminum gutters and downspouts is to serve as the primary material for manufacturing these components. Aluminum coils are processed and formed into the desired shape and size to create the gutters and downspouts. The coils provide the necessary strength, durability, and resistance to corrosion that are essential for these exterior building elements.

How are aluminum coils used in the automotive industry for fuel tank construction?

Aluminum coils are commonly used in the automotive industry for fuel tank construction as they are lightweight, corrosion-resistant, and can be easily formed into various shapes. These coils are typically rolled and welded to create fuel tank shells. The use of aluminum coils helps to reduce the overall weight of the vehicle, improving fuel efficiency. Additionally, aluminum's excellent corrosion resistance ensures that the fuel tank remains durable and long-lasting.

What is the role of aluminum coils in the production of pharmaceutical packaging?

The role of aluminum coils in the production of pharmaceutical packaging is to provide a lightweight and flexible material that offers excellent barrier properties against moisture, light, and oxygen. These coils are used to create aluminum foil, which is then used to package pharmaceutical products such as tablets, capsules, and powders. The foil acts as a protective barrier, ensuring the integrity and stability of the medication by preventing contamination and degradation. Additionally, aluminum coils are easy to handle and can be easily molded into various shapes and sizes, making them ideal for packaging different pharmaceutical forms.

What are the potential future innovations in aluminum coil technology?

Some potential future innovations in aluminum coil technology include the development of lighter and stronger alloys, improved corrosion resistance, enhanced thermal conductivity, and advancements in manufacturing processes such as continuous casting and rolling. Additionally, there is potential for the integration of smart technologies, such as sensors and monitoring systems, to optimize coil performance and enable predictive maintenance. Other areas of focus may include sustainability initiatives, such as developing more eco-friendly production methods and recyclable materials.

Wholesale Aluminum Coils from supplier in Estonia

We understand the unique requirements of the Estonian market and can offer customized solutions to meet your specific needs. Our experienced team is dedicated to providing excellent customer service and ensuring timely delivery of high-quality products.

Our Aluminum Coils are manufactured using advanced technology and strict quality control measures to ensure durability and performance. We offer a variety of grades, sizes, and finishes to cater to different applications.

In addition to supplying Aluminum Coils, we also provide sales support, including quotations and technical assistance. Our knowledgeable team can help you select the right product for your project and provide guidance on installation and maintenance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer comprehensive procurement solutions, ensuring a hassle-free process from start to finish.

Whether you are a contractor, distributor, or end-user, we are committed to exceeding your expectations and becoming your trusted partner for Aluminum Coils in Estonia. Contact us today to discuss your requirements and discover how we can meet your needs.

Our Aluminum Coils are manufactured using advanced technology and strict quality control measures to ensure durability and performance. We offer a variety of grades, sizes, and finishes to cater to different applications.

In addition to supplying Aluminum Coils, we also provide sales support, including quotations and technical assistance. Our knowledgeable team can help you select the right product for your project and provide guidance on installation and maintenance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer comprehensive procurement solutions, ensuring a hassle-free process from start to finish.

Whether you are a contractor, distributor, or end-user, we are committed to exceeding your expectations and becoming your trusted partner for Aluminum Coils in Estonia. Contact us today to discuss your requirements and discover how we can meet your needs.