All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

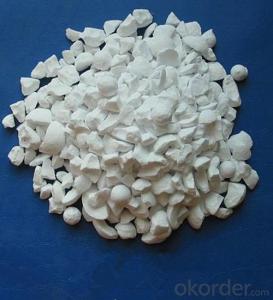

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials resist corrosion from molten slags?

Refractory materials resist corrosion from molten slags due to their high melting points and chemical inertness, which prevent them from reacting with the corrosive elements present in the slags. Additionally, refractory materials have dense and non-porous structures that provide a barrier against the penetration of molten slags, further enhancing their resistance to corrosion.

How do refractory materials contribute to the prevention of product contamination?

Refractory materials contribute to the prevention of product contamination by providing a barrier between the product and the surrounding environment, preventing any contaminants from coming into contact with the product. These materials have high melting points and excellent thermal insulation properties, allowing them to withstand high temperatures and protect the product from external contaminants. Additionally, refractory materials are chemically stable, which prevents any reactions or interactions with the product that could lead to contamination. Overall, their use ensures the integrity and purity of the product, ensuring that it meets the required quality standards.

What are the different types of refractory coatings for insulation?

Some different types of refractory coatings for insulation include ceramic coatings, epoxy coatings, and silicone coatings. Ceramic coatings are made from materials such as alumina, zirconia, or silica and provide high-temperature resistance. Epoxy coatings offer excellent adhesion and chemical resistance, making them suitable for various applications. Silicone coatings are known for their flexibility, weather resistance, and thermal stability, making them ideal for insulation in extreme environments.

Wholesale Refractory Materials from supplier in Estonia

Whether you are in need of refractory bricks, castables, mortars, or any other refractory materials, we have you covered. Our products are sourced from leading manufacturers worldwide, ensuring high quality and reliability.

In addition to our wide range of products, we also offer various services to meet your specific requirements. Our team of experienced professionals can provide technical consultations, on-site inspections, and customized solutions for your projects. We understand the unique challenges that come with working in the refractory industry and strive to provide the best possible support to ensure the success of your projects.

As a subsidiary platform of CNBM, we have access to a vast network of resources and expertise. This allows us to offer competitive prices, efficient logistics, and timely delivery to our customers in Estonia. Our strong relationship with suppliers also enables us to stay up-to-date with the latest industry trends and developments, ensuring that we always provide the most innovative and advanced refractory materials to our customers.

At CNBM, customer satisfaction is our top priority. We are committed to providing you with a seamless and hassle-free procurement experience, from the initial inquiry to the final delivery. Our dedicated team is always ready to assist you and provide the necessary support throughout the entire process.

Choose us as your trusted partner for all your refractory materials needs in Estonia. Contact us today to discuss your requirements and let us help you find the best solutions for your projects.

In addition to our wide range of products, we also offer various services to meet your specific requirements. Our team of experienced professionals can provide technical consultations, on-site inspections, and customized solutions for your projects. We understand the unique challenges that come with working in the refractory industry and strive to provide the best possible support to ensure the success of your projects.

As a subsidiary platform of CNBM, we have access to a vast network of resources and expertise. This allows us to offer competitive prices, efficient logistics, and timely delivery to our customers in Estonia. Our strong relationship with suppliers also enables us to stay up-to-date with the latest industry trends and developments, ensuring that we always provide the most innovative and advanced refractory materials to our customers.

At CNBM, customer satisfaction is our top priority. We are committed to providing you with a seamless and hassle-free procurement experience, from the initial inquiry to the final delivery. Our dedicated team is always ready to assist you and provide the necessary support throughout the entire process.

Choose us as your trusted partner for all your refractory materials needs in Estonia. Contact us today to discuss your requirements and let us help you find the best solutions for your projects.

Hot Search

- Monolithic Refractories in Paraguay

- Ceramic Fiber Products in Liechtenstein

- Refractory Bricks in Mali

- Raw Materials For Refractory in Switzerland

- Raw Materials For Refractory in Belarus

- Raw Materials For Refractory in Ghana

- Refractory Bricks in Serbia

- Monolithic Refractories in Norway

- Monolithic Refractories in Colombia

- Refractory Bricks in Croatia