Painted Aluminum Sheets for Sale - Color Prepainted Aluminium Coils for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

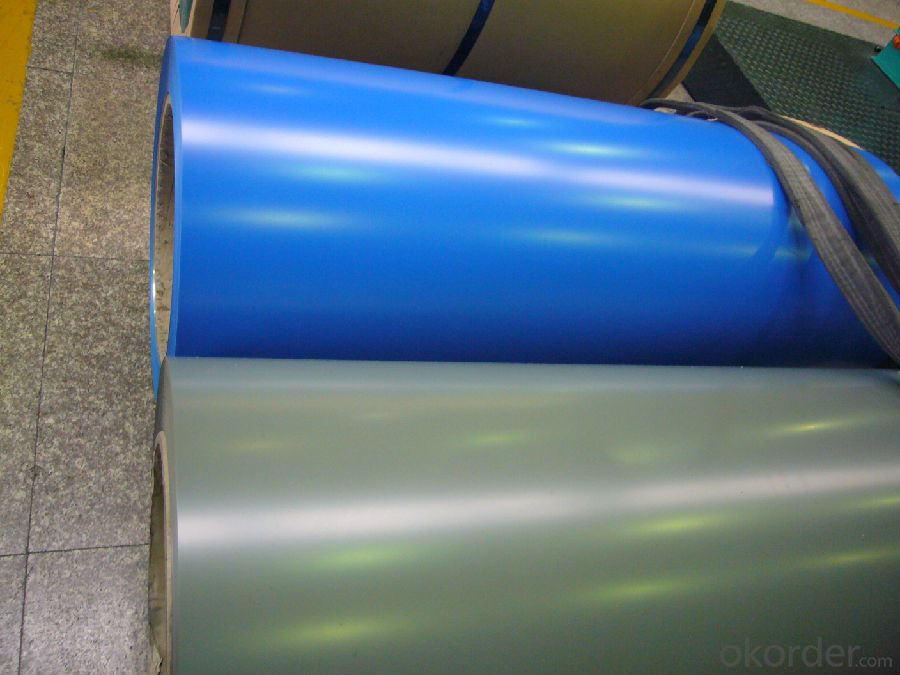

1.Structure of Color Prepainted Aluminium Coils for Composite Panel

Color Prepainted Aluminium Coils for Composite Panel is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Prepainted Aluminium Coils for Composite Panel

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What specific criteria or standards must be met when utilizing recycled aluminum in construction?

- <p>Recycled aluminum products used in construction projects must meet specific requirements to ensure safety, durability, and compliance with building codes. These include adherence to ASTM standards for recycled aluminum alloys, such as ASTM B601 for ingots and ASTM B209 for rolled or cold finished products. The recycled aluminum must also have consistent mechanical properties and corrosion resistance comparable to virgin aluminum. Additionally, the products should be free from contaminants that could compromise structural integrity. It's crucial to verify the source and processing methods of recycled aluminum to ensure it meets these standards before use in construction.</p>

- Q: Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Yes, aluminum sheets can be used for manufacturing chemical storage tanks. Aluminum is corrosion-resistant and has good strength-to-weight ratio, making it suitable for storing various chemicals safely.

- Q: Are aluminum sheets suitable for interior design applications?

- Yes, aluminum sheets are suitable for interior design applications. They are versatile, lightweight, and durable, making them an excellent choice for modern and contemporary design styles. Aluminum sheets can be used for various purposes, such as wall panels, ceilings, backsplashes, furniture, and decorative accents, adding a sleek and sophisticated look to any interior space. Additionally, aluminum is easy to clean and maintain, making it a practical and aesthetically pleasing option for interior design.

- Q: Explain the similarities and differences in the properties of aluminum metal, Al(s) and aluminum oxide (a salt) Al203(s) in terms of the particles and forces present.. thanks doods!

- Aluminum metal is not found in nature, only aluminum oxide is in the mine or ground and they have to separate it from the oxidation to make a useful metal.

- Q: Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Guangdong Huayuan prosperous is the largest aluminum plate supplier 021-56808701, in Shanghai / Tianjin / Chongqing have logistics and storage, domestic aluminum plating surface coating treatment is less than imports, stamping coating is easy to fall,

- Q: Is it possible to use aluminum sheets for roofing purposes?

- <p>Yes, aluminum sheets can be used as roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is a popular choice for both residential and commercial roofing due to its low maintenance requirements and long lifespan.</p>

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- 101 aluminum sheets are not appropriate for applications involving conductive heat transfer. This specific aluminum alloy, known as 101 aluminum, is commercially pure and has a low electrical conductivity. Consequently, it is ineffective at efficiently conducting heat, rendering it unsuitable for situations requiring heat transfer. Instead, it is advisable to employ alloys with higher thermal conductivity, such as 6061 or 7075 aluminum, for conductive heat transfer applications. These alloys possess superior heat transfer properties and are commonly utilized in heat sinks, heat exchangers, and other scenarios demanding efficient heat transfer.

- Q: Are the aluminum sheets suitable for manufacturing solar panel backings?

- Yes, aluminum sheets are suitable for manufacturing solar panel backings. Aluminum is a widely used material in the solar industry due to its excellent properties. It is lightweight, durable, and corrosion-resistant, making it ideal for outdoor applications. Additionally, aluminum has a high thermal conductivity, allowing it to dissipate heat effectively, which is crucial for solar panels to operate efficiently. Furthermore, aluminum is easily recyclable, making it a sustainable choice for solar panel manufacturing. Overall, aluminum sheets are a suitable material for manufacturing solar panel backings.

- Q: Are the aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is highly resistant to corrosion and weathering, making it an ideal choice for outdoor use. Additionally, aluminum sheets are lightweight, durable, and have excellent thermal and electrical conductivity, further enhancing their suitability for various outdoor applications.

- Q: What is the corrosion resistance of aluminum sheets?

- Aluminum sheets have excellent corrosion resistance due to the formation of a protective oxide layer on their surface, which prevents further oxidation or corrosion.

Send your message to us

Painted Aluminum Sheets for Sale - Color Prepainted Aluminium Coils for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords