Extruded Aluminum Trim Profiles for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium section profiles for doors and windows Description

Aluminium section profiles for doors and windows is one semi-finished aluminium material. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium section profiles for doors and windows

Aluminum Profiles | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium section profiles for doors and windows

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium section profiles for doors and windows

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium section profiles for doors and windows

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

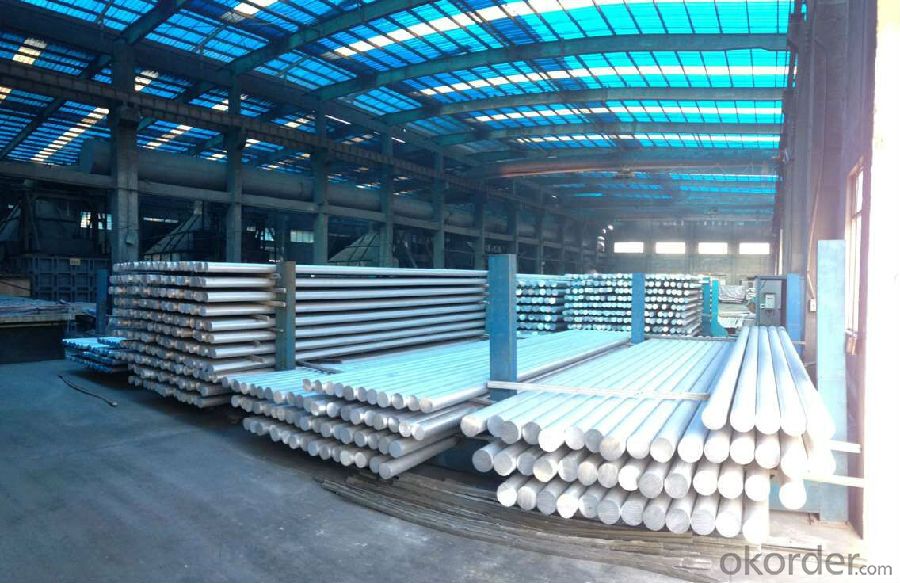

6. Image of Aluminium section profiles for doors and windows

7. Package and shipping of Aluminium section profiles for doors and windows

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Acrylic coating principle, coating on the aluminum section, he and fluorocarbon powder spraying, what is the difference

- Compared with the other two spraying methods, the best quality, the most beautiful appearance, but the price is expensive, not green. Used in high-end buildings, commercial building more

- Q: What are the different accessories available for aluminum profiles?

- There are various accessories available for aluminum profiles, such as corner connectors, end caps, T-slot nuts, brackets, hinges, handles, leveling feet, and panel fasteners. These accessories help enhance the functionality and versatility of aluminum profiles in different applications, such as constructing frames, enclosures, and machinery.

- Q: Is it possible to utilize aluminum profiles in the construction of carports or garages?

- <p>Yes, aluminum profiles can be used for carports or garages. They are known for their durability, corrosion resistance, and lightweight properties, making them ideal for such structures. Aluminum profiles are also easy to install and maintain, and they can withstand various weather conditions without rusting. This material is commonly used for the framing and support structures in carports and garages, offering a cost-effective and long-lasting solution.</p>

- Q: Are aluminum profiles suitable for earthquake-resistant structures?

- Yes, aluminum profiles can be suitable for earthquake-resistant structures. Aluminum is lightweight and flexible, allowing it to absorb and dissipate the energy generated during an earthquake. Additionally, aluminum profiles have excellent strength-to-weight ratio and corrosion resistance, making them a suitable choice for seismic applications. However, the design and engineering of the structure, along with appropriate reinforcement, are crucial factors in ensuring its earthquake resistance.

- Q: What are the cost considerations for using aluminum profiles?

- Some cost considerations for using aluminum profiles include the initial cost of purchasing the profiles themselves, any additional costs for custom or specialized profiles, the cost of installation and assembly, maintenance costs, and potential future costs for repairs or replacements. Additionally, the cost of aluminum profiles may vary depending on the quality and thickness of the material used.

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a construction project.

- <p>To calculate the amount of aluminum profiles needed for a building project, follow these steps: 1. Determine the design specifications and dimensions of the project, including the length, width, and height of the structure. 2. Identify the types and sizes of aluminum profiles required based on the structural needs and design. 3. Calculate the total linear footage of each profile type needed by multiplying the length of each required section by the number of sections. 4. Add up the total linear footage for all profile types. 5. Account for waste and cutting losses, typically adding 5-10% to the total. 6. Ensure the calculations comply with building codes and safety standards. Consult with engineers or architects if necessary.</p>

- Q: What is the difference between aluminum alloy and 6063-T5 6060-T66?

- 6060-T66, higher strength, average mechanical performance is higher than T6 under 20-30Mpa condition [T66 is in T6 (solid solution strengthening + fully artificial aging) condition, strengthened by special process status - in European standard can be found] 6063-T5 is the most common aluminum alloy and delivery condition, and most of the architectural profiles are applied

- Q: This question asks for the method to determine the amount of aluminum required for a construction project.

- <p>To calculate the weight of aluminum profiles needed for a building project, follow these steps: 1. Determine the length and cross-sectional area of each aluminum profile required. 2. Use the aluminum density, which is approximately 2.7 grams per cubic centimeter (g/cm鲁). 3. Multiply the volume (length 脳 cross-sectional area) by the density to get the weight of each profile. 4. Sum the weights of all profiles to get the total weight needed. Ensure to account for any additional material for joints, connections, and potential waste. It's also advisable to consult with an engineer or use specialized software for precise calculations tailored to your project's specific requirements.</p>

- Q: This question asks about the characteristics of aluminum profiles, specifically whether they are lightweight and easy to handle.

- <p>Yes, aluminum profiles are known for their lightweight nature and ease of handling. They are made from aluminum, which is a lightweight metal with a low density. This makes aluminum profiles ideal for applications where weight is a concern, such as in construction, automotive, and aerospace industries. Additionally, their lightweight characteristic also contributes to their ease of handling, as they can be easily maneuvered and installed without requiring heavy machinery or excessive manpower.</p>

- Q: Can aluminum profiles be used for electrical bus ducts?

- Yes, aluminum profiles can be used for electrical bus ducts. Aluminum is a commonly used material in the electrical industry due to its excellent conductivity and lightweight properties. It offers great electrical conductivity, which is crucial for transmitting electrical power efficiently. Additionally, aluminum profiles are durable, corrosion-resistant, and can withstand high temperatures, making them suitable for various industrial applications. However, it's important to consider the specific requirements and regulations of the project to ensure the aluminum profiles meet the necessary electrical and safety standards.

Send your message to us

Extruded Aluminum Trim Profiles for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords