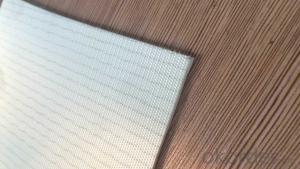

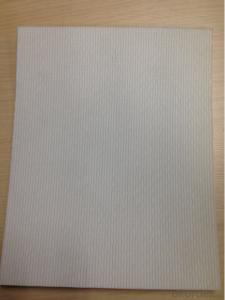

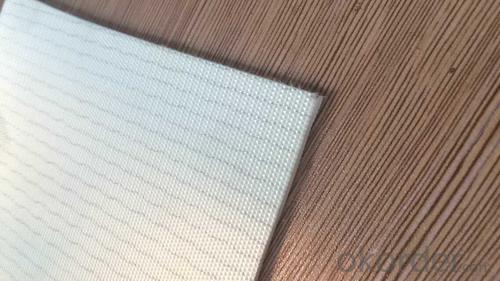

3.0mm White Food Grade Felt Surface PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3.0mm White Food Grade Felt Surface PVC Conveyor Belt

Conveyor Belt Description:

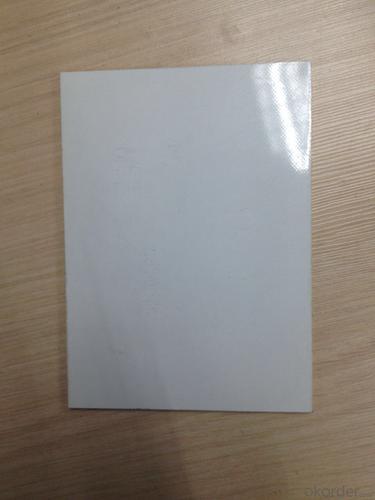

Color White

Fiber layers 2 plies

Fiber class Lateral stability polyester fabric

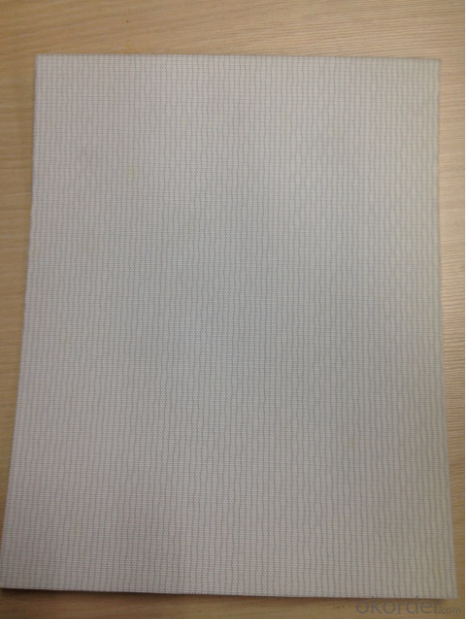

Surface material Wool felt

Surface pattern --

Bottom material Polyester fabric

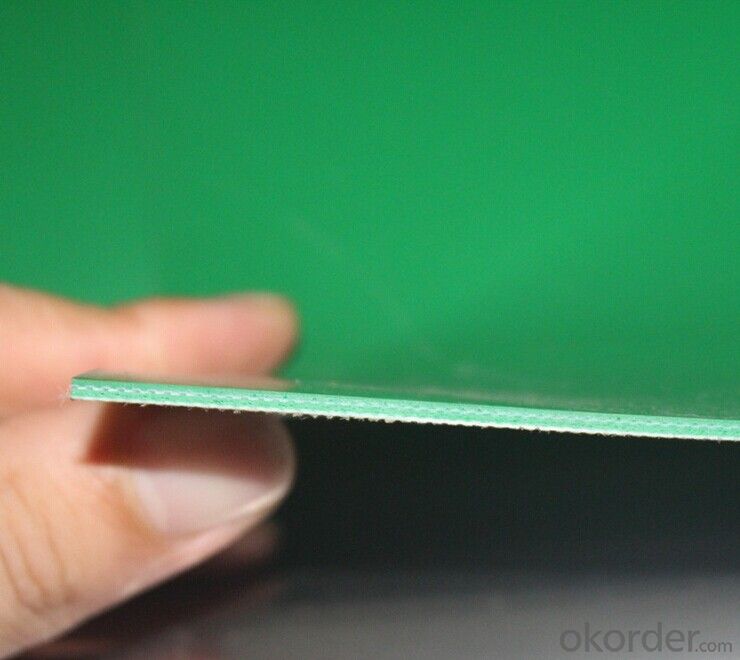

Total thickness 3.0mm

Surface coated thickness 1.0mm

Weight 2.9kg/sqm

Maximum width 2200mm

Elongation 1% force 10N/mm

Hardness shoreA --

Working temperature -10~+80℃

Minimum pulley diameter 80mm

Application Pallet or roller conveyor.Food bakery industry.

Conveyor Belt Feature

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Endless belt splicing;

10)Special wear resistant edge design;

Conveyor Belt Applications

Food industry

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Can olive nets be used to protect against hail damage?

- No, olive nets are not typically used to protect against hail damage. Hailstones are larger and heavier than olives, which makes the nets ineffective in preventing hail damage to crops or structures.

- Q: What are the factors that determine the longevity of an olive net?

- The factors that determine the longevity of an olive net include the quality and durability of the net material, proper installation and maintenance techniques, exposure to environmental elements such as sun, wind, and rain, frequency of use, and overall care and handling of the net.

- Q: White plastic for a long time. Why does it turn yellow?

- There are plastic products called plasticizers of raw materials, mainly plays the role of anti-aging, but it will be volatile in the air, so when increased when plasticizer reduced, the color will also fade, the elastic plastic shriveled, becomes very brittle, it will turn yellow.

- Q: What glue does it stick to plastic?

- If it is small things glued to the plastic parts, you can use 502 of the quick drying glue. If the whole piece of plastic cracking, such as bumpers, to the car repair shop burning plastic welding, because the car wash plastic products have a certain thickness, the general speed drying glue even if stuck, but not force.

- Q: Can olive nets be used to increase yield?

- Yes, olive nets can be used to increase yield. These nets are specifically designed to protect olive trees from external factors like pests, harsh weather conditions, and bird damage. By using olive nets, farmers can ensure a higher percentage of fruit retention, better pollination, and improved overall fruit quality. Additionally, the nets can also aid in controlling the amount of sunlight that reaches the olive trees, leading to more consistent and even ripening of the olives, thus increasing the overall yield.

- Q: How do olive nets prevent olives from being damaged by small mammals?

- Olive nets prevent olives from being damaged by small mammals by creating a physical barrier that prevents the animals from accessing the trees or the ground beneath them. The tightly woven mesh of the netting acts as a deterrent, making it difficult for the mammals to reach and consume the olives. Additionally, the nets are often installed at a height above the ground, making it even harder for the animals to climb up and reach the olives. Overall, olive nets serve as a protective shield, keeping the olives safe from potential damage caused by small mammals.

- Q: Can olive nets be used in different weather conditions?

- Yes, olive nets can be used in different weather conditions. These nets are designed to protect olive trees and their fruit from various weather elements such as wind, rain, and hail. They are typically made from durable materials that can withstand different weather conditions, ensuring the safety and productivity of olive trees regardless of the weather outside.

- Q: How do olive nets impact the overall water requirements of the olive tree?

- Olive nets, specifically used for harvesting olives, do not directly impact the overall water requirements of the olive tree. However, the use of olive nets can help conserve water indirectly by preventing water loss due to evaporation and reducing weed growth around the tree, which in turn allows more water to be available for the olive tree's uptake.

- Q: Can olive nets be used for both outdoor and greenhouse olive cultivation?

- Yes, olive nets can be used for both outdoor and greenhouse olive cultivation. Olive nets are designed to protect the olive trees and their fruits from birds and other pests. Whether in an outdoor orchard or a greenhouse, these nets can be installed to prevent damage and ensure a successful harvest.

- Q: Can olive nets be used in regions with high humidity levels?

- Yes, olive nets can be used in regions with high humidity levels. Olive nets are designed to protect the olives from birds and other pests, and they can effectively do so regardless of the humidity level. However, it is important to note that high humidity can promote the growth of mold or fungal diseases on the olives, so proper care and maintenance should be taken to ensure the olives remain healthy and unaffected.

Send your message to us

3.0mm White Food Grade Felt Surface PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords