Geocell Soil Reinforcement 100% New HDPE China Manufature Geoweb Confinement system

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

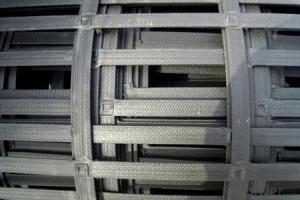

***What are Geocells or cellular confinement systems?

Geocell is a kind of geosynthetics that is widely used in soil reinforcement, erosion control projects. Geocell, also known as cellular confinement systems is a three-dimensional structure made from high-density polyethylene (HDPE) strips. It can expand on-site to form a honeycomb-like structure and filled with sand, soil, rock, gravel, or concrete. Easy and simple. The cellular confinement system has been proven to be a trustable solution to soil reinforcement, slope protection, and retaining walls.

We , as one of the largest geocell manufactures, we are able to offer you the same products at a more competitive price.

***What kinds of geocell do we have?

There are five different standard geocell specifications,it can satisfy most project's requirement. You can review the detailed Geocell datasheet below. If you find the specification is obviously higher or lower than your request, feel free to send us an email to specify your requirements. We will contact you in 24 hours.

Material Properties | |||||||

Polymer Density (ASTM D 1505) | g/cm3 | 0.935-0.965 | |||||

Environmental Stress Crack Resistance (ASTM D 1693) | hrs | >5000 | |||||

Carbon Black Content (ASTM D 1603) | % | 1.5% --2% | |||||

Nominal Sheet Thickness before texturing (ASTM D 5199) | mm | min. 1.27-5%,+10% | |||||

Nominal Sheet Thickness after texturing(ASTM D 5199) | mm | min. 1.52-5%,+10% | |||||

Material | Compound of various Polyethylenes and additives | ||||||

Texture | Polyethylene strip consists of a multiple rhomboidal indentations, over the entire strip on both sides of the strip.The indentations have a surface density of 22 to 32 per cm2 | ||||||

Perforations | Polyethylene strip is perforated with horizontal rows of maximum 10mm diameter holes. Cell perforations area is less than 12% of cell surface area. | ||||||

Cell/ Section Properties | |||||||

Property | Unit | GM330 | GM356 | GM445 | GM660 | GM712 | |

Weld Spacing | mm | 330 | 356 | 445 | 712 | 1000 | |

Cell Depth | mm | 75, 100, 125, 150, 200 | |||||

Expanded(± 3%) Cell Dimensions | Width | mm | 244 | 259 | 320 | 508 | 707 |

Length | mm | 210 | 224 | 287 | 475 | 707 | |

Expanded(± 3%) Cell Area | cm2 | 250 | 289 | 460 | 1206 | 2500 | |

Nominal(± 3%) Expanded Section | Width | mm | 2.44 | 2.59 | 2.56 | 2.56 | 5.66 |

Length | mm | 6.1 | 6.5 | 8.35 | 13.72 | 11.31 | |

Nominal(± 3%) Expanded Section Area | m2 | 14.9 | 16.8 | 21.4 | 35.1 | 64.0 | |

Seam Properties | Cell Depth | ||||||

mm | 75 | 100 | 125 | 150 | 200 | ||

Seam Peel Strength(EN ISO 13426-1,Method B: Peeling Test) | N | 1065 | 1420 | 1775 | 2130 | 2840 | |

(Other sizes are available to order) | |||||||

***What is geocell used for?

Geocell is the ideal product for soil reinforcement. It can greatly improve the bear capacity thanks to its three-dimensional structure. In many scenarios (various roads, airstrips, container yards, parking lots), in order to improve the bearing capacity of the road surface, reduce uneven settlement, and reduce maintenance costs in the later period, the geocell will be the best choice. Besides, geocell is widely used in slope protection, retaining walls, channel lining.

Cellular Confinement Systems have been used to improve the performance of both paved and unpaved roads by reinforcing the soil in the subgrade-base interface or within the base course. The effective load distribution of geocell creates a strong, stiff 3D cellular mattress which can reduce vertical differential settlement into soft subgrades, improves shear strength, and enhances load-bearing capacity while reducing the amount of aggregate material required to extend the service life of roads.

Retaining Walls

Slope Protection

Road Support

Channel Lining

***What are the advantages of using geocell?

Easy to install

Reduce cost and time

Environmentally friendly

Up to 70 years of service life

FAQ

1. How about the delivery time?

Lead time: 1-3 weeks on receipt of 30% T/T deposit.

2. What's is the MOQ?

1000m2

3. How to deal with the sample charge?

Samples are free, and we only charge the freight. We will return the sample freight in the future order.

4. Can you produce the product according to customers' requirements?

Sure, we are a professional manufacturer, OEM and ODM are both welcome.

- Q: Can olive nets be used in combination with weed control methods?

- Yes, olive nets can be used in combination with weed control methods. The nets can help prevent weed growth by blocking sunlight and reducing weed seed germination. Additionally, they can serve as a physical barrier that prevents weeds from growing near the olive trees. However, it is important to note that olive nets alone may not completely eliminate weeds, so it is recommended to use them in conjunction with other weed control methods such as mulching or herbicides for effective weed management.

- Q: Are there any maintenance tips for olive nets during the off-season?

- Yes, there are a few maintenance tips for olive nets during the off-season. Firstly, it is important to clean the nets thoroughly to remove any dirt or debris. This can be done by gently brushing or shaking the net to dislodge any particles. Secondly, ensure that the nets are stored in a dry and well-ventilated area to prevent mold or mildew growth. Additionally, inspect the nets for any signs of damage such as tears or holes, and repair or replace them if necessary. Finally, it is recommended to store the nets in a protected area away from pests or rodents that may chew or damage them. Following these maintenance tips will help ensure that the olive nets remain in good condition and are ready for use in the next harvest season.

- Q: What is the purpose of using an olive net?

- The purpose of using an olive net is to collect olives during the harvesting process. The net is spread out under the olive trees, acting as a catchment system to prevent the olives from falling to the ground and getting damaged. This allows for easier collection and minimizes waste, ensuring a more efficient and productive olive harvest.

- Q: Are there any specific guidelines for using olive nets on olive trees with delicate branches?

- Yes, there are specific guidelines for using olive nets on olive trees with delicate branches. It is important to choose a net with a fine mesh size to prevent any damage to the delicate branches. Additionally, the net should be properly secured to avoid any entanglement or breakage of branches. Regular monitoring and adjustment of the net is also necessary to ensure it is not causing any harm to the tree.

- Q: How do you know when it's the right time to install olive nets?

- The right time to install olive nets is typically determined by the maturity of the olives. It is recommended to install the nets when the olives have reached their desired ripeness and are ready for harvesting. Additionally, weather conditions and the presence of pests or birds in the orchard can also influence the decision to install olive nets.

- Q: How do you install an olive net?

- To install an olive net, first, determine the size of the net needed to cover the desired area. Then, secure one end of the net to a sturdy structure such as posts or trees. Stretch the net tightly across the area, ensuring it is evenly distributed. Finally, secure the opposite end of the net to another sturdy structure. Adjust and tighten the net as needed to ensure proper coverage and support for the olive trees.

- Q: What additives are used in plastics?

- The main requirements for plastic additives are: high efficiency: can effectively play its functions in the plastics processing and application. The comprehensive performance requirements should be based on the selection of additives mixing. The compatibility with synthetic resin better compatibility. The persistence: volatile in plastics processing and application process no exudation, does not migrate, dissolution. The chemical stability: no decomposition in plastics processing and application process, and the synthetic resin and other components of chemical reaction. The non-toxic, without any toxic effects on the human body. The price is low.

- Q: Can olive nets be used in combination with trellis systems?

- Yes, olive nets can be used in combination with trellis systems. Olive nets are commonly used to protect olive trees and their fruits from birds, and they can be installed over trellis systems to provide effective bird deterrent while still allowing the olive trees to grow and climb along the trellis.

- Q: How do olive nets prevent olives from getting damaged during rain or hailstorms?

- Olive nets prevent olives from getting damaged during rain or hailstorms by providing a protective barrier between the olives and the falling precipitation. The nets act as a shield, intercepting the rain or hail and preventing it from directly hitting the olives. This helps to minimize the impact and potential damage caused by the force of the falling water or ice, preserving the quality and integrity of the olives.

- Q: Can olive nets be used in regions with extreme weather conditions?

- Olive nets may not be suitable for regions with extreme weather conditions as they are typically designed for protecting olives from birds and insects rather than withstanding harsh weather elements.

Send your message to us

Geocell Soil Reinforcement 100% New HDPE China Manufature Geoweb Confinement system

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords