Cellular Confinement System of Geocells - HDPE Geogrid with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

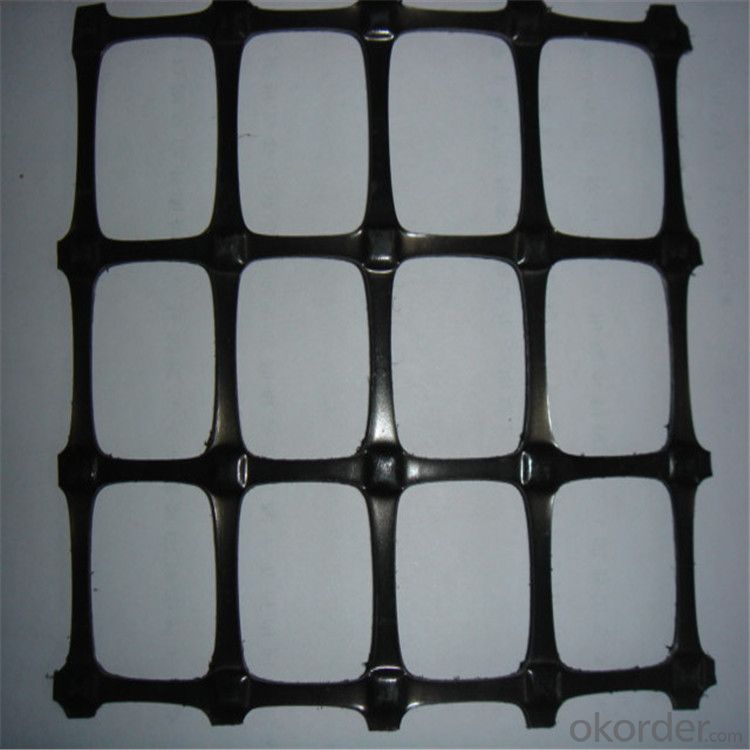

HDPE Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched

into regular mesh pattern, and finally stretched in the longitudinal direction.

Application:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1) strengthen land loading capacity

and extend its service life.

2) convenient to construct ;

reducing area , project cost and maintenance cost.

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

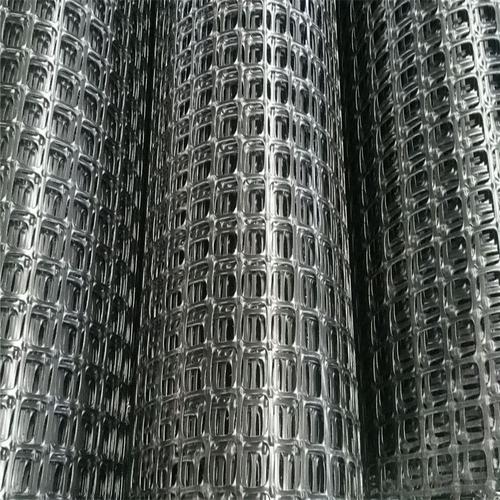

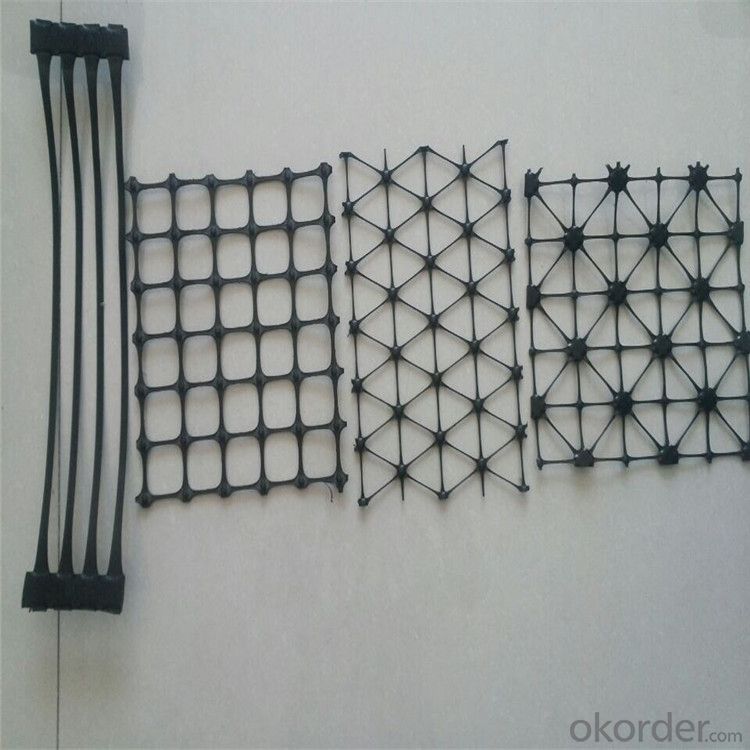

Images of HDPE Biaxial Geogrid

- Q: What is the effect of soil type on geogrid performance?

- The effect of soil type on geogrid performance can vary. Different soil types have varying levels of strength, compaction, and drainage capabilities, which can impact the ability of the geogrid to properly reinforce the soil. For example, cohesive soils with high clay content may cause the geogrid to experience reduced tensile strength and limited interlocking capability. On the other hand, granular soils with good drainage properties may enhance the geogrid's performance by allowing better load distribution. Therefore, understanding the soil type is crucial in determining the suitability and effectiveness of geogrid installation for soil reinforcement.

- Q: What are the geotechnical testing items for Subgrade?

- Longitudinal and transverse tensile strength and elongation

- Q: Who knows how much the staggered distance of the lap joint of the geogrid is?

- Straight and smooth and close to the cushion, all longitudinal or transverse lap joints should be staggered, overlapping length shall not be less than 300MM.

- Q: What is the price of 50kN two-way geogrid

- There are plastic steel, but also more than 4Specializing in the production of geogrid,

- Q: Are geogrids suitable for use in mining applications?

- Yes, geogrids are suitable for use in mining applications. Geogrids are highly versatile and can be used in various mining operations such as soil stabilization, slope reinforcement, and retaining wall construction. They provide excellent tensile strength, durability, and resistance to high loads, making them ideal for supporting heavy mining equipment and preventing soil erosion. Additionally, geogrids can enhance the stability and safety of mining sites, reducing the risk of slope failures and improving overall operational efficiency.

- Q: What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are both geosynthetic materials used in geotechnical applications, but they have distinct differences. Geogrids are typically made from high-strength polymers, such as polypropylene or polyester, and have a grid-like structure. They are used to reinforce soil, providing tensile strength and preventing soil erosion. Geogrids are commonly used in road construction, retaining walls, and slope stabilization projects. On the other hand, geosynthetic clay liners (GCLs) consist of a layer of bentonite clay sandwiched between two geotextiles. The clay component of GCLs gives them excellent hydraulic barrier properties, making them highly effective in containment applications. GCLs are commonly used in landfills, mining sites, and other projects that require the containment of liquids or gases. In summary, while geogrids reinforce soil and provide tensile strength, geosynthetic clay liners act as hydraulic barriers and are used for containment purposes.

- Q: How much is the steel plastic geogrid?

- Steel plastic geogrid 50KN, 4.5 yuan per squareSteel plastic geogrid 60KN, 5 yuan per square

- Q: What is the purpose of using the three - way geogrid in the gravel layer

- Reinforced with three - way geogrid

- Q: In the case of the subgrade with Geogrid

- When the subgrade for soft foundation treatment using geogrid, geogrid is used as reinforcement of reinforced earth structure or reinforced material, the main function is to play the role of tensile.

- Q: Can geogrids be used in geothermal energy systems?

- Yes, geogrids can be used in geothermal energy systems. Geogrids are often used to reinforce soil structures and provide stability, which can be beneficial in supporting the infrastructure and components of geothermal energy systems. They can help prevent soil erosion, provide load-bearing capacity, and enhance the overall performance and longevity of the system.

Send your message to us

Cellular Confinement System of Geocells - HDPE Geogrid with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords