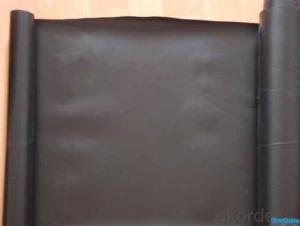

Pipes Anti-Rust Sleeve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

1. Product produced according to ISO8180

2. Thiciness 200um, 400um and other thickness is available upon request

3. Black color, other color is available upon request

4. Corbon black content 2-3

5. Puncture Resistance ≥900

6. Breack strength ≥20

7. Breack elongation ≥500

8. Tear resistance ≥20

Usage:

For Ductile iron pipe DN80-DN2000.

- Q: How do olive nets prevent olives from being damaged by frost?

- Olive nets prevent olives from being damaged by frost by creating a protective barrier around the olive trees. These nets act as a shield, blocking the cold air and frost from directly reaching the olives. This helps to maintain a more stable temperature around the olives, preventing them from freezing and ultimately reducing the risk of damage caused by frost.

- Q: How does the cost of using olive nets compare to other harvesting methods?

- The cost of using olive nets tends to be lower compared to other harvesting methods.

- Q: How do olive nets prevent olives from being damaged by small mammals?

- Olive nets prevent olives from being damaged by small mammals by creating a physical barrier that prevents access to the olive trees. The nets are typically made of strong and durable material, such as nylon or polyethylene, which cannot be easily chewed through by small mammals like squirrels or rodents. These nets are placed over the olive trees, covering the entire canopy, and secured tightly to prevent any gaps or openings. This ensures that the olives remain protected and inaccessible to the small mammals, effectively preventing them from causing damage or consuming the olives.

- Q: How much is plastic PP5 resistant to cold?

- Copolymerization of PP is generally more common than ordinary poly PP, low temperature, usually twice as much, that is, -20 degrees.

- Q: Can olive nets be used for olive tree bonsai training?

- Yes, olive nets can be used for olive tree bonsai training. These nets are commonly used to protect olive trees from birds and other animals, but they can also be utilized to shape and train the branches of bonsai trees. By carefully placing the nets over the tree and adjusting them as needed, one can guide the growth of the olive tree bonsai and achieve the desired aesthetic.

- Q: Can olive nets be used for olive tree training from seedlings?

- Yes, olive nets can be used for olive tree training from seedlings. Olive nets are commonly used to support and train young olive trees by guiding their growth in a desired direction. The nets provide stability and prevent the seedlings from bending or breaking under their own weight. By attaching the nets to sturdy posts, the seedlings can be trained to grow vertically, allowing for better light exposure and air circulation.

- Q: Can olive nets be used to protect against frost damage?

- Yes, olive nets can be used to protect against frost damage. These nets act as a physical barrier, trapping warm air around the olive trees and preventing frost from settling on the branches and fruits. They can help to maintain a stable microclimate, reducing the risk of frost damage to the olive crop.

- Q: Can olive nets be used on olive trees grown in raised beds?

- Yes, olive nets can be used on olive trees grown in raised beds. Olive nets are commonly used to protect the tree's fruit from birds and other animals, regardless of whether the trees are grown in raised beds or in the ground. They provide a physical barrier that prevents pests from accessing the fruit, ensuring a higher yield and better quality harvest.

- Q: What are the common plastics?

- Polyvinyl chloride (PVC): common in building materials. It is rarely used in food packaging, which is prone to harmful substances at high temperatures and is released even during manufacture.

- Q: How do olive nets prevent olives from being damaged by hailstorms?

- Olive nets act as a protective barrier over the olive trees, preventing hailstones from directly hitting the olives. The nets absorb the impact of the hailstones, reducing the force with which they hit the olives, thus minimizing potential damage.

Send your message to us

Pipes Anti-Rust Sleeve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords