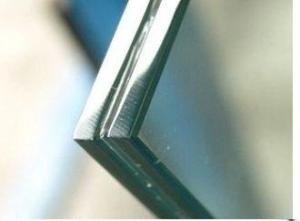

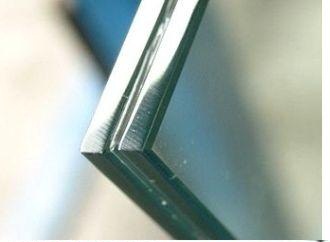

Coated laminated glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

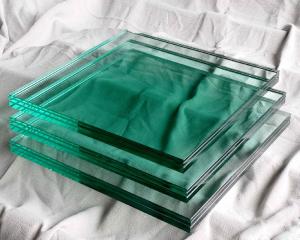

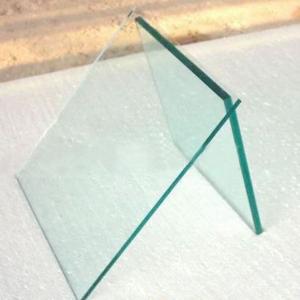

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q: what is an ideal roof for a steel framed building with glass cladding?

- each floor could be of concrete slab, or concrete decking, the last roof could be of corregated sheets with translucent panels for natural lighting , glass cladding is an architectural element and not structural element

- Q: What is the difference between the span on the architectural glass and the width of the glass?

- Span is the length of the window, the glass width is the height of the window frame!

- Q: Now many people say that architectural glass film can be energy-saving, it is how to save energy in the end? Its energy-saving principles and energy-saving parameters how to quantify?

- I say, mainly rely on reflection to heat, natural air conditioning will not open so much, this is not energy, as the coefficient, businesses have test equipment

- Q: Are building glasses exhibited at Guangzhou Aluminum Window, Door & Facade Expo?

- yes, at the Guangzhou aluminum windows fair, you will see all types of building glasses including low-E glass, insulating glass, fire-proof glass, Heat reflective coated glass, Tempered Glass, Silk-screened Glass Laminated glass, Glass Flooring , Curved tempered glass, building glass film, solar-energy BIPV, molecular sieve, warm edge strip and other insulating glass interval products ., etc

- Q: There is a 100 story high building. We have 2 identical glasses. We would like to know the highest floor from which it is possible to drop a glass and not have it broken on the ground. What is the least number of experimental drops we need in order to determine the answer? (and how so?)I know it is less than 19.

- 7 drops should be needed to be sure. #1 drop from the 50th floor breaks, go to 25. Doesn't break, goto 75 # 2 breaks from 25, goto 12. Doesn't break from 25, goto 37 # 2 breaks from 75, goto 62. Doesn't break from 75, goto 87 # 3 breaks from 12, goto 6. Doesn't break from 12, goto 18 # 3 breaks from 37, goto 31. Doesn't break from 37, goto 43. # 3 breaks from 62, goto 68. Doesn't break from 62, goto 56. # 3 breaks from 87, goto 81. Doesn't break from 87, goto 93. As you can see, each drop allows you to cut the min-max distance by 1/2. Within 6 or 7 tries you should have a valid answer. Ok, with your new I info I have a new answer. :) Least number of drops = 2 (floors 10 and 1 (both break) Most number of tests = 18. (floor 99) Drop from floors 12 1+11 24 2+11 36 3+11 48 4+11 60 5+11 70 6+9 80 7+9 90 8+9 100 9+9

- Q: Architectural glass companies need to apply for which qualification documents

- The material of the glass consists of three parts: basic raw materials, flux and colorant, as well as decolorizing agent, clarifying agent and emulsifier.

- Q: I bought a tempered glass film online, but I will not paste, I will not paste around, how do?

- First clean the phone screen, Mobile phone film is generally 3 layers, the need to paste the film is the middle of the outside, respectively, on both sides of the two, that is, 1 and 2. First look under the marked number 1, tear him, the middle of the film and the phone screen Alignment, press the (carefully Bubble, slowly scraping), paste after the removal of the other outside the outer membrane label 2, you can, how specific alignment of their own master, can not help you.

- Q: I'm putting glass Block windows in my barn. A lot of them. I need to build all the openings first. When figuring out my openings I need to allow for the gaps between the blocks and around the edge. What should that gap be?

- Glass masonry units are typically square, and are available in nominal 6, 8, and 12 in. sizes. Rectangular units are also available. Actual sizes are 1/4 in. less to allow for the typical 1/4 in. mortar joints. Unit thicknesses are either "standard" 3-7/8 in. or "thin" 3-1/8 in. or 3 in. for hollow units and for solid units respectively. Thin unit panels are typically used in residential and light commercial applications. For exterior applications you will want to add integral water repellents to the mortar to prevent water penetration. If you are talking about what size of an opening to use for your windows. That will depend on what the "rough opening" dimension is based on the window manufacturer. Typically is is 1 in. larger than the window size. This gives you 1/2 in. space all around the window for shims and alignment.

- Q: What is the tempered glass? What is the difference with ordinary glass?

- Tempered glass is actually a kind of prestressed glass, in order to improve the strength of the glass, usually using chemical or physical methods (physical means that the wind quenching, the current building glass are used in this method) in the glass surface to form compressive stress, glass bear external force When the first to offset the surface stress, thereby enhancing the carrying capacity, improve the glass tensile strength. The main advantages of tempered glass are two, the first is the strength of several times higher than the ordinary glass, bending strength is 3 to 5 times the ordinary glass, the impact strength is 5 to 10 times the normal glass to improve the strength at the same time also increased The security. The use of safety is the second major advantage of tempered glass, its increased carrying capacity to improve the fragile nature, even if the destruction of tempered glass was no small angle of the small pieces of damage to the human body greatly reduced. Tempered quenching and cooling properties of tempered glass than ordinary glass has 2 to 3 times the increase, generally can withstand more than 150 ℃ temperature difference, to prevent the thermal cracking has a significant effect. From the appearance of the general do not see how much different with ordinary glass, but through the polarized sunglasses can be seen on the tempered glass with rainbow plaque - some of the old micro-van front can also be seen, this is tempered glass The unique phenomenon.

Send your message to us

Coated laminated glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords