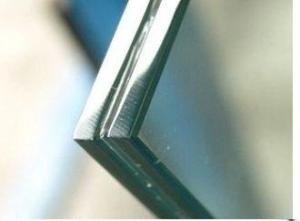

Coated laminated glass 8+1.52pvb+8 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q: How to identify the glass film is good or bad? Identify glass sheets should pay attention to those matters?

- Identify the glass film is good or bad a total of eight points: 1, hand touch .2, Nose smell 3 ,. seeing 4, quality assurance card 5. with alcohol, gasoline, asphalt cleaning agent and other chemical reagents 6. Technical parameters 7. Scratched. 8. Is the product of the packaging and the original product manufacturers have detailed product model, address, telephone, website, bar code.

- Q: What does LOW-E mean in architectural glass?

- Simply put, low-e glass is low-radiation glass, solar energy can be far from the infrared part of the energy reflected back to play a role in energy saving!

- Q: Is the cutting of complex or glass this thing is expensive or the store chaos price ~ Why those who set the glittering glass necklace ah headdress ah earrings ah bracelet so expensive I am actually not interested in this just want to know what the stone so expensive

- In fact, glass is not ruthless, Is crystal ruthless, Because the glass is the best crystal imitation items, Looks ruthless like crystal, so ruthless

- Q: effects of rain, heat, pressure, snow

- If you are planning to start on your woodworking project, this isn't something you should use, it's something that you would be insane not to.

- Q: High - rise building doors and windows glass area requirements

- Buildings need to use glass as the following parts of building materials must use safety glass: (A) 7 floors and 7 floors above the building outside the window; (B) of the window area greater than 1.5m2 or glass bottom edge of the final decoration surface less than 500mm of the floor window; (3) curtain wall (except for the whole glass screen); (Four) tilt the installation window, all kinds of ceiling (including skylights, lighting top), ceiling; (5) staircases, balconies, platform corridors of the fence and atrium lining; (6) the entrance, entrance hall and other parts of public buildings; (7) other parts of the body that are vulnerable to impact and impact.

- Q: How can we quickly see the MAX model which has heavy problems such as architectural glass

- With a laser pen to see whether the two points in the same line can be

- Q: What is the main part of the safety glass used in the building?

- Mainly used in public safety caused by hidden parts, such as the door, glass curtain wall, and the car front block, bank counter operating area, to prevent radiation, splash, observation and so on.

- Q: What are the shortcomings of the explosion-proof membrane itself? Will there be any adverse consequences?

- Explosion-proof film than ordinary insulation film thickness, so that the glass is not easy to be crushed, if the film is selected when the poor quality of the brand, when the danger occurs when you want to break the glass from the car to escape are not easy, so that the explosion- Hidden film. Another explosion-proof membrane insulation rate is relatively low, generally not as good as the effect of insulation film.

- Q: Glass quality standards

- Glass sub-kiln and small kiln of the sub-kiln is the float glass. Float glass thickness uniformity, transparency is good, through the glass to see things will not be deformed, high quality. Small kiln glass: thin uneven, through the glass to see things deformation, the quality of the times. Glass thickness: from 2 mm to 2 to 20 mm.

- Q: Can acrylic panels do roofing materials?

- Using a new type of polyester material, by hot-forming or plane trim, metal base built-in light source, great visual impact. Weathering: panel coated with high concentrations of UV absorbers, metal base sprayed imported car paint, can be long lasting weather, never fade, the service life of up to 5 to 8 years. Durability: The product has a good protection against the built-in light source, extending the service life of the light source. Reasonable: rational design, rain and moisture; open structure, easy maintenance. Impact resistance: 200 times the glass product, almost no risk of fracture. Transparency: up to 93%, translucent excellent, soft light, bright. Flammability: Non-flammable and self-extinguishing. Aesthetics: exquisite craft, the whole font was mirror effect, the base without wrinkles, no seams, all riveting firmware is not exposed. Energy-saving: light transmission performance, the corresponding reduction in light source products, electricity, reduce the use of cost. Talk about plexiglass acrylic (acrylic) PMMA commonly known as plexiglass, also known as acrylic or acrylic, Hong Kong people called Acrylic, is an important early development of thermoplastic, with good transparency, chemical stability and weather resistance, easy to dye, easy Processing, beautiful appearance, in the construction industry has a wide range of applications. Plexiglass products can usually be divided into casting plates, extruded plates and molding compounds.

Send your message to us

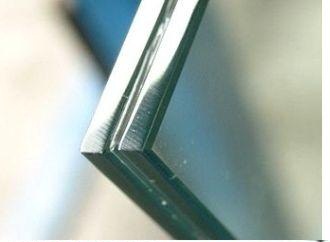

Coated laminated glass 8+1.52pvb+8 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords