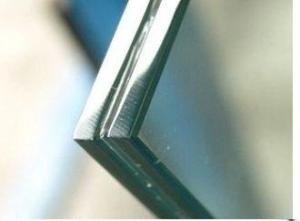

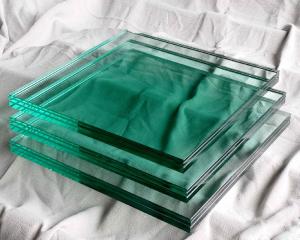

Coated laminated glass 6+0.72pvb+6 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q: Korea architectural glass film brand

- Now a lot of Korean film is actually domestic to do, but South Korea's raw materials, the specific brand about to know

- Q: In the kitchen glass lid heating process, it is necessary to remove the heated glass cover from the heating furnace and transfer it to the conveyor belt in the specified direction for subsequent process. Currently rely on manual operation, due to high temperature radiation production conditions are bad, there is no alternative to artificial approach?

- Features and functions: ??????? 1) run the game can be configured to run smoothly to avoid mechanical resonance. 2) accurate positioning, running a continuous impact of small mechanical. 3) Simple and reliable operation, maintenance-free. 4) During the transit process, there is a 180 degree flip process action to facilitate the next step to work. 5) The transit time is maintained for 3 to 6 seconds, which is conducive to improving product quality. 6) on the edge of the glass cover to protect, to avoid the defective.

- Q: Architectural glass film is generally used to brand which is more ah

- According to the actual situation of the correct choice of architectural glass film, OKorder Chang Bao construction staff engaged in architectural glass film for several years, very good

- Q: The Louvre pyramid in Paris, France, is built of glass panes. There are 4 panes in the top row, and each additional row has 4 more panes than the previous row. 1.Write a series in summation notation to describe the total number of glass panes in n rows of the pyramid. 2.If the pyramid were made of 18 complete rows, how many panes would it have? 3.The actual pyramid has 11 panes less than a complet 18-row pyramid because of the space for the entrance. Find the total number of panes in the Louvre pyramid.

- So the first row has 4 panes, the second 8, the third 12, and so on. The nth row would have 4n panes. 1. The total number of glass panes in n rows is 4*1 + 4*2 + 4*3 + ... + 4n or, in summation notation: n ∑ 4i i=1 2. n=18 4*1 + 4*2 + 4*3 + ... + 4*18 = 4 (1+2+3+ ... + 18) = 4 * 18 * 19 / 2 [using the well-known formula for triangular numbers*] = 36*19 = 684 * T(n) = n(n+1)/2 3. 684-11 = 673

- Q: Clip glass anti-theft glass, folder wire glass, discoloration glass, heat-absorbing glass and eating glass information.

- Are you a fifth grade last semester? You should be looking for this: folder silk glass Clamp glass also known as shredded glass or wire glass. It is produced by the calendering method, that is, in the glass melting state will be preheated steel wire or wire into the middle of the glass, the annealing, cutting made. The glass surface can be embossed or polished, and the color can be made into a colorless, transparent or colored. Clamp glass is characterized by good safety and fire resistance. Clamp glass due to the role of steel mesh skeleton, not only to improve the strength of the glass, and when the impact or the sudden change in temperature and damage, the fragments will not fly, to avoid the debris on the human injury. In the event of fire, when the flame extension, folder glass glass heat burst, due to the role of metal wire, glass can still be fixed, isolated flame, it is also known as fire glass. According to the national industry standard JC433-91 stipulates that the thickness of the laminated glass is divided into: 6,7,10mm, size is generally not less than 600mm × 400mm, not more than 2000mm × 1200mm. At present, China's production of laminated glass is divided into folder embossed glass and folder polished glass two categories. Clamp glass can be used for building doors and windows, skylights, lighting roof, balcony and other parts. Am i right??

- Q: I am planning a winter project, we have several nice lakes here. Any ideals?

- tons of boats are a combo of wood and fiberglass... my old 16' v bottom had very thin plywood hull with fiberglass reinforcement on both sides. actually ive seen people use other boats to use as a mold for a fiberglass hull...

- Q: Not man-made destruction of tempered glass why suddenly broken

- Tempered glass has bleed characteristics This is because the glass raw materials containing nickel sulfide crystals, is the world's existing manufacturing technology can not be completely avoided, only through the purity of raw materials and processing technology to control the risk of a little lower blew. On the concept of self-blasting rate, our country only on the external walls of the engineering glass has a national standard, I do not know whether the foreign industry for the use of tempered glass also has detailed provisions. One ton of glass raw materials, there are at least 3-4 nickel sulfide crystals, this one ton of glass made of several square meters of the size of the glass, which will have 3-4 tablets blew, which is blew the image depicting.

- Q: Glass for building construction mainly.

- It's not one of our main products, so probably a little here, a little there.

- Q: I need it by tonight

- Call the city of Memphis, Tennesse. They did it.

- Q: LOW-E insulating glass U value than ordinary hollow glass much lower

- Ordinary insulating glass 2.6 or more, LOW-E insulating glass 1.9 or less.

Send your message to us

Coated laminated glass 6+0.72pvb+6 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords