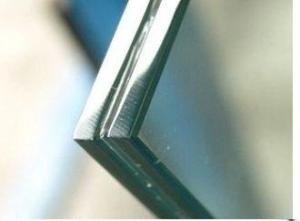

Coated laminated glass 8+1.14pvb+8+15A+8 building glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q: What is the name of the hollow glass I am doing?

- Suggestions called energy-saving related names better! National policy will help you!

- Q: What is the LOW-E (double silver) glass shading coefficient?

- Double silver low-e glass shading coefficient, probably range between .02-0.4, because the specific color of the specific data is not the same.

- Q: Is there a way to reduce the noise

- With the continuous development of society, noise pollution problems are more and more serious, especially in the city of traffic noise constantly plagued the general public, here mainly to introduce some of the static noise glass knowledge for everyone to share!

- Q: The world invented several kinds of glass

- Laminated glass is usually made of two ordinary flat glass (also can be tempered glass or other special glass) and glass between the organic adhesive layer composition.When the damage, the debris is still attached to the adhesive layer, to avoid the debris Splash on the human body. Used for safety requirements of the renovation project. ?Bulletproof glass. In fact, is a kind of laminated glass, but the composition of the glass used more high-strength tempered glass, and the number of sandwich is relatively more. Used in the bank or luxury and other security requirements of the very high decoration works in. ?Roving glass. Made of flat glass heating softening in the mold forming, and then by the annealing of the curved glass. In some high-level decoration in the frequency of getting higher and higher, need to be scheduled, no cash. Glass tiles. The production process of glass tiles is basically the same as flat glass, the difference is the molding method. The middle of the dry air. Used for decorative items or insulation requirements of the light through the shape. Cellophane. Also known as glass film, with a variety of colors and colors. According to the performance of different paper, with different performance. Most of the insulation, anti-infrared, anti-ultraviolet, explosion and so on.

- Q: Worried about the bathroom glass will blew, paste the security film can be resolved?

- Paste the security film can solve this problem, the bathroom is generally equipped with more tempered glass, tempered glass itself has three thousandth of the blasting rate, can be used to solve the Long film safety film. Paste the safety film can increase the function of the glass, and the glass will not be so easy to break. Can be solved.

- Q: I'm drawing a building and a part of it cylindrical and all covered with colored glass sheets, and i don't know how to show all that together: that it's glass, colored and cylindrical, so if anyone has any idea I'd be thankful :)

- Shade that section as if it WERE a cylindar. Even glass panes look different in the shade than those sections that are in full sunlight. If your elevation is rendered in color, you can add gradiated touches of light blue to darker blue to indicate the curvature of the section. If it's black and white, then use greys. It it is strictly a line drawing then darker and more numerous streaks of black lines can create the shaded effect.

- Q: How will the glass color fade

- The color of the vitreous itself is not faded because the color itself is through thousands of degrees of high temperature burned in the daily life of several temperature simply can not make it color. Our common architectural glass, red, blue, green, gold, are coated glass.

- Q: My new house all the glass without the 3C logo, is not unqualified?

- 1, if you want to check whether the glass is qualified, it should be cut before the glass is not checked, after cutting you can not check the 3C Peugeot. (In general this is the case). 2, insulating glass: insulating glass invented by the Americans in 1865, is a good insulation, noise, beautiful and applicable, and can reduce the building weight of the new building materials, it is two (or three) glass , The use of high-strength high air tightness composite binder, the glass and desiccant containing aluminum alloy frame bonding, made of high-performance insulation glass insulation. Hollow glass is superior to ordinary double-layer glass, so it has been recognized around the world, the insulating glass is two or more pieces of glass with effective support evenly separated and sealed around the seal, so that the formation of dry between the glass layer of gas Space glass products. The main material is glass, aluminum spacing, bending bolt, butyl rubber, polysulfide, desiccant. 3, safety glass: a class of severe vibration or impact is not broken, even if broken is not easy to hurt the glass. Including tempered glass, laminated glass and so on. For doors and windows of cars, aircraft and special buildings. 4, tempered glass: tempered glass is actually a kind of prestressed glass, in order to improve the strength of the glass, usually using chemical or physical methods, the formation of compressive stress on the glass surface, the glass bear the external force first offset the surface stress, thereby enhancing the carrying capacity , Enhance the glass itself, wind pressure, cold and heat, impact and so on.

- Q: I saw some of them in the high-rise buildings on the glass window posted a film, which can see outside, outside can not see inside, what is the film? Are you expensive?

- Building glass insulation film. good results! you get what you pay for!

Send your message to us

Coated laminated glass 8+1.14pvb+8+15A+8 building glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords