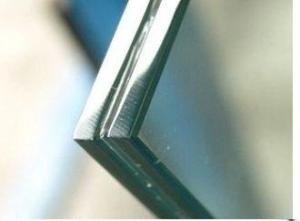

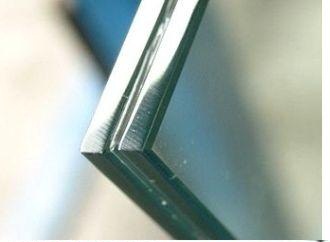

Coated laminated glass 8+1.14SGP+8 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q: What is the name of the building in France with the glass pyramid in front of it?

- The Louvre

- Q: i want to build a glass reptile terrarium with the measurements 4 foot in length x 2 foot in width x 1 1/2 foot high for 100$ or under need to know where to buy the glass for cheep (8mm thick) and hoe to seal it with no wood just like one i would buy at a pet store and how to make the mesh lid please reply asap thanks

- I looked at the Petsmart website and it is cheaper to buy one but you can probly get all those things at a home improvment store ex. Home Depot Glass=For windows Screen=The screen used on windows The sealer is near the paint

- Q: it would be awesome to have glasses with a built in computer.

- yes you can but there would have to be batteries or a cord included

- Q: Just wondering, because i went to Paris recently, and that glass pyramid, i know is for enterance, but WHY a glass pyarmid, and not something that actually blends in with the rest of the palace? it is completely out of place there.

- With every day pass, our country is getting into more and more trouble. The inflation, unemployment and falling value of dollar are the main concern for our Government but authorities are just sleeping, they don’t want to face the fact. Media is also involve in it, they are force to stop showing the real economic situation to the people.

- Q: Is there a standard for frosted glass in the bathroom?

- 1. Safety glass shall be used and the thickness shall meet the requirements of Table 7.1.1-1 and 7.2.4 of 7.1 of JGJ113-2009; 2. Recommended by the professional design and installation.

- Q: If there is no air conditioning at home, how to make the room cooler,

- Balcony green, courtyard green. Balcony courtyard green, planting trees and flowers, not only has a high ornamental value, but also the role of regulating the climate, will make the air fresh, cool and pleasant. Because the green plants can shade, but also through the evaporation of leaves to achieve the role of cooling. Data show that in the courtyard balcony planted grapes, morning glory, climbing wall tiger and some flowers, can be attached to the wall cooling 5 ℃ ~ 14 ℃, so that indoor cooling 2 ℃ ~ 4 ℃.

- Q: Through the glass after the sun came in with the glass can not be compared to those who will be the skin of the sun more black ah? Seek experts

- So that the skin is black, is the sun in the ultraviolet. Ultraviolet rays are wavelengths shorter than visible light. The wavelength is between 390 and 400 nm. It can pass through the air, but it is not easy to pass through the glass, has the ability to sterilize, and has some damage to the eyes and skin.

- Q: Insulation glass 3C certification to investigate what time to start

- China's State Administration of Supervision, Inspection and Quarantine and the State Certification and Accreditation Administration Committee on December 3, 2001 together issued a "mandatory product certification management regulations", included in the list of 19 categories of 132 kinds of products, "unified directory, unified standards And the assessment procedures, unified signs and uniform charges "mandatory certification management. 3C "certification from May 1, 2003 (later postponed to August 1) from the full implementation. Safety glass belongs to the first batch of products

- Q: The duration of the main material inspection report of construction works

- Stop valve test report is valid!

- Q: Vray all the glass material to give Fresnel reflection?

- I have a situation, I just made an outdoor lens, architectural glass with the VRAY, gave Fresnel, and then adjusted the curve.

Send your message to us

Coated laminated glass 8+1.14SGP+8 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords