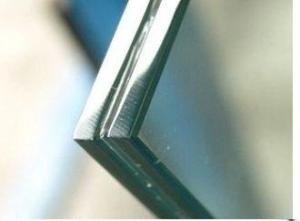

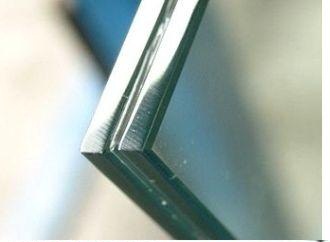

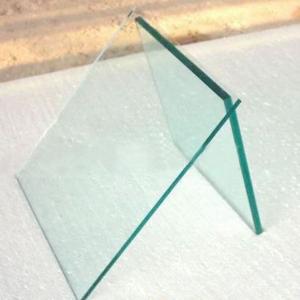

Coated laminated glass 8+1.14pvb+8+15A+8 Color glass Hollow glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q: Imitate a new type of glass this lesson, introduce a glass you want to invent the characteristics and role

- New glass Dust is a hard-to-reach enemy, just finished cleaning, it will come again.I hope that there is a vacuum-proof glass, can suck the dust on the glass, the average daily adsorption is equivalent to you do not sweep a year But it is easy to clean up.As long as the glass won, soaked in water, it is as soft as a rag. Gently rinse, immediately clean and then loaded back, it began its vacuum work , This glass is suitable for people who love the clean home or do not have time to clean the office workers home, absolutely useful.

- Q: My living room west sun, want to paste a window in the insulation film. Will the glass insulation film is doing? Are you going to work? Will the house darken?

- Hello: Insulation film is affixed to the inner surface of architectural glass to improve the performance and strength of glass, so that it has insulation, heat insulation, energy saving, anti-riot, anti-ultraviolet, landscaping appearance, to avoid privacy, security and other functions, Car glass and building doors and windows, partitions, roof and so on. The use of foil glass and the use of ordinary flat glass, tempered glass, semi-tempered glass compared to the security has been greatly improved. The third layer: anti-ultraviolet isolation layer; the fourth layer: radiation protection; the first layer: the first layer: transparent layer of plastic protective layer; Isolation layer; fifth layer: metal insulation film layer; sixth layer: AAA, PET base layer; seventh layer: fixed adhesive layer; eighth layer: antioxidant isolation layer; ninth layer: wear Coating layer; tenth layer: aerobic neutral coating. Paste the effect is very good, and will not affect the lighting.

- Q: What is the good insulation of the glass film

- Common car waste film features are: ?? 1, opened the protective layer of garbage when you can smell the pungent odor, some of the jelly film pungent temperature is relatively serious. ?? 2, start with the effective, long time can not be very good insulation, separated by ultraviolet light. (Waste film in the adhesive is only added a little heat insulation chemicals and anti-ultraviolet chemicals, use a little longer or too high heat, it will soon be distributed or the reaction, loss of the original function) ?? 3, the use of garbage in the process prone to fade, cracking, blistering and other conditions.

- Q: Now many people say that architectural glass film can be energy-saving, it is how to save energy in the end? Its energy-saving principles and energy-saving parameters how to quantify?

- Coated glass and hollow glass composite: including thermal reflective coating insulating glass and low-emissivity insulating glass. The former can also reduce the heat transfer coefficient and shading coefficient, which is better light transmission. The type and function of architectural glass foil

- Q: Why do you need 3C certification for tempered glass?

- 3C certification has now covered tempered glass. Most large glass manufacturers, have been certified by 3C, and in the product on the note. Some small businesses, there may be no such certification, or did not realize that there is no 3C logo. Emphasis is that 3C is mandatory.

- Q: Has anyone built a greenhouse using discarded sliding glass doors?

- glass gets to hot and will burn the plants unless you have a temp control

- Q: What is architectural glass?

- Architectural glass (architectural glass) is the main varieties of flat glass, with a smooth surface, translucent, sound insulation, insulation, wear resistance, climate change, material stability and so on. It is made of quartz sand, sandstone or quartzite, limestone, feldspar, dolomite and soda ash as the main raw material. It is made by crushing, sieving, batching, high temperature melting, molding, annealing, cooling and processing. The function of architectural glass is no longer just to meet the lighting requirements, but to have to adjust the light, thermal insulation, security (bulletproof, anti-theft, fire, radiation, anti-electromagnetic interference), art decoration and other characteristics. With the continuous development of demand, glass molding and processing technology has also been a new development. Now, new technologies such as interlayer, tempered, ion exchange, glazed decoration, chemical thermal decomposition and cathodic sputtering have been developed to increase the amount of glass in the building and become the third largest building behind cement and steel material. Let you know about building glass.

- Q: Is the car 's annual inspection posted directly on the glass and can affix the solar film?

- First affixed to the sun film in the paste year mark

- Q: Building decoration commonly used varieties of light and heat glass

- Many types of glass, according to the chemical composition can be divided into soda-lime glass, aluminum-magnesium glass, potassium glass, borosilicate glass, lead glass and quartz glass.

- Q: What is the principle of self-cleaning of self-cleaning glass? Why is it called self-cleaning glass?

- Broadly speaking, self-cleaning glass is the ordinary glass in a special physical or chemical treatment, so that the surface of the unique physical properties, so that the glass is no longer through the traditional manual scrubbing method to achieve the effect of cleaning glass. The surface of the glass like a lotus leaf, the water on its surface will form a drop of water down, so dirty is not easy to attach up to achieve self-cleaning function of the glass. This type of cleaning nano-technology self-cleaning agent is a typical representative: ECOFRIEND-ING4 nano glass self-cleaning products! Glass self-cleaning technology in the developed countries has been very popular in Europe and the United States on the market almost all of the glass must be self-cleaning type.Therefore, with the development of cleaning technology wave, ECOFRIEND-ING4 nano glass self-cleaning agent this cleaning revolution "leader "Came to China, to the Chinese bath room to bring environmental protection, health and safety of the new concept of scientific development!

Send your message to us

Coated laminated glass 8+1.14pvb+8+15A+8 Color glass Hollow glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords