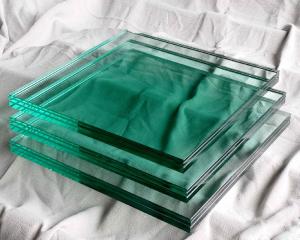

Insulating Glazing 5mm+12A+5mmInsulating Glazing 5mm+12A+5mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

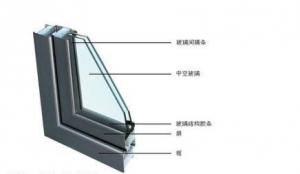

we introduced the advanced production lines (with automatic coating removing, automatic sealing system) and equipped with reverse osmosis deionized water preparation and storage equipment, automatic aluminum spacer bending equipment, low-e glass coating removing equipment, which is able to produce all kinds of specifications of insulating glass for customers. The production lines that are equipped with automatic vertical sealing system, abandon the disadvantages of traditional horizontal sealing (there will be no patch phenomenon), make the processed insulating glass more flat and smooth..

Insulating glass size specifications:

Maximum processing size: 2440 mm * 3500mm

Minimum processing size: 200 mm * 200 mm

Aluminum spacer specifics: 6 mm, 9 mm, 12 mm, 16 mm

Glass thickness: 3 mm to 19 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q: Alright, so I want to build an under seat sub woofer enclosure for my smaller sports coupe. There's not much room at all under the seats, so I was thinking about going with a Pioneer 8" shallow mount sub, but the box is causing me a bit of a headache. I haven't had a chance to take a measuring tape to it, and doing so would be difficult.My idea is to get a can of the spray foam stuff used to seal homes, to inflate a garbage bag under the seat. After letting it sit and dry for a while, I'll remove the seat, pull the bag out with the exact dimensions of my seat and then play from there. I'll take the bag off of the foam and probably sand it down from there to fit my needs. I'll then use fiber glass to build up the box from the foam mold.Any thoughts on better ways to do this?PS: The car is a 2000 Mercury Cougar incase anyone has actual dimensions.

- you can take the seat out and then use a think foil paper and line under the seat then put a thin layer of fiber glass then let it dry and go from there also. * remember when your using the fiberglass your also gonna want to put a layer of bondo to strengthen the box but you do have a good idea also what ever works.

- Q: I wanted to build a glass ant farm but instead of using wood or plastic for the frame I wanted to use molding clay. Can I use the clay to build the frame to hold the two pieces of glass and to make a removable top or will it hurt my ants???

- Using plaster would be better than clay. Fired ceramic clay would also be fine, but that gets fairly complicated. If you use plaster it will be fairly easy, but you have to build a frame for your ant farm out of wood or use a suitably sized plastic or strong cardboard box. You could take a plastic box, put one plane of glass down. Use modeling clay to make the chambers for your ant farm. Make sure you connect them. Then mix plaster and cover everything so high you can still see your chambers. Put second pane of glass on it. After plaster has set, you should be able to remove one pane of glass, get out the modeling clay, then put the pane back on, you can use small clamps if necessary. Plaster is pretty good for an ant farm since it soaks up water. You don't want an ant farm to be absolutely dry, that isn't good for the ants. They need a certain humidity. Of course you don't want it really wet either, you'll have to observe the ants to see what they prefer. You can water the ant farm periodically or put one side into water so it soaks up some water. You also have to move the ants to a new ant farm once in a while, since the ant farm will become dirty. Make sure you feed the ants proteins and not just sugar. Make sure you have an ant queen. A good way to start an ant farm is to collect a queen if you see one outside. Since ants swarm, that is a good time to find a lot of queens. Make sure the queen doesn't have wings any more, only then she is mated.

- Q: Who knows the manufacturer of architectural glass film ah

- I have heard that someone has to do, but as far as I know is to buy abroad has been completely out of the equipment to produce, and the original equipment is the production of the lowest file of the kind of equipment in the country can only find agents. Proud of the shield of the membrane should be good

- Q: Is the cutting of complex or glass this thing is expensive or the store chaos price ~ Why those who set the glittering glass necklace ah headdress ah earrings ah bracelet so expensive I am actually not interested in this just want to know what the stone so expensive

- There are several reasons for the precious glass: 1, the ancient law glass material of particularity, and its craft is very complex and difficult, the ancient method of making the glass is quite complex, the fire to the water, to dozens of processes to complete the ancient method of glass Boutique production, very time-consuming, and some light production process will be more than ten days, and mainly rely on hand-made. Which is very difficult to grasp the various links, the heat to grasp the harder to say that half of the skills by half with luck. ? 2, the glass is worth a lot of craft art, its price is higher than the crystal, only a baked, the yield is only 70%. More critical is that the ancient method of glass can not be recycled, unlike gold and silver products, that is, once there is a little problem, ten days, dozens of processes, how many people's efforts immediately put down the flow, so its cost is very high. ? 3, glass is a cultural product, not just a material, more importantly, the glass products are unique, the world does not have exactly the same glass products.

- Q: Why is the glass transparent? What is extended is water, ice and so on transparent things Please explain from the principle, simply, you do not ask Glass reflected light and other objects reflect the light is nothing different, Why some objects can be transparent, and some objects are not transparent

- The transparency should mean that its transmittance is relatively large, and the reflectivity is smaller

- Q: effects of rain, heat, pressure, snow

- depends on the weather conditioons best way to solvethis question is to test different materials

- Q: I am making a stained glass panel with a lighthouse in it and I want to put windows and doors in the lighthouse. Do I cut them out somehow or put something over the glass

- you need to cut them out

- Q: What is Article 20 of the Regulations on Safety Management of Building Glass?

- Four of the "building safety glass management regulations" (development and operation [2003] 2116) only 14, is not the twelfth ah? Article 12 Penalties ??(1) The safety glass production enterprise shall bear the corresponding legal responsibility for the serious economic loss or personal injury or death caused by the quality of the safety glass itself. The quality supervision department shall supervise and inspect the quality of its products and, if it fails to meet the quality requirements, It shall impose penalties on it, and the compulsory certification body shall revoke its certification certificate in accordance with the relevant provisions. According to the relevant provisions of the punishment, the certification body should bear the relevant legal responsibility. ??(2) The sales unit shall bear the corresponding legal responsibility for the unit that sells the unqualified safety glass in violation of these Provisions and the major economic loss or personal injury or death caused by the products it sells. ??(3) Any trade contract involving the import of unqualified safety glass in violation of these Provisions shall be subject to corresponding legal liability for causing significant losses or personal injury or death caused by the imported products. ??(4) The construction, design, construction and supervision units that violate these Provisions shall be punished by the construction administrative department in accordance with the relevant provisions. The unit that sells the unqualified safety glass in violation of the provisions shall be investigated and dealt with by the administrative department for industry and commerce according to law.

- Q: What is the material?

- If the glass is laminated glass, then the inside should be folder semi-transparent film so become a semi-transparent glass

- Q: Tough glass film is good or matte film good?

- In terms of economic benefits, matte film is the best choice, and from the phone side, the tempered glass film is the best choice. Tempered glass belongs to safety glass. The tempered film is to prevent the phone from falling when the screen is broken. Not to scratch. Ordinary film are the hardness of 3H, the use of a few months will not have too much scratches, the reason why the election of steel screen is because: high hardness and low toughness, the phone fell, can be a good shade screen. When the phone fell to the ground, bear the impact of a large, tension over the big screen on the broken. Low toughness of the tempered film When the phone is out of tension when the film will bear the tension so greatly reduced the main screen to bear the tension.

Send your message to us

Insulating Glazing 5mm+12A+5mmInsulating Glazing 5mm+12A+5mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches