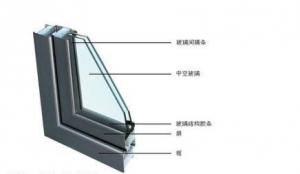

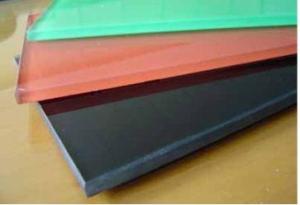

A variety of colors of insulating glass 8mm+12A+6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

we introduced the advanced production lines (with automatic coating removing, automatic sealing system) and equipped with reverse osmosis deionized water preparation and storage equipment, automatic aluminum spacer bending equipment, low-e glass coating removing equipment, which is able to produce all kinds of specifications of insulating glass for customers. The production lines that are equipped with automatic vertical sealing system, abandon the disadvantages of traditional horizontal sealing (there will be no patch phenomenon), make the processed insulating glass more flat and smooth..

Insulating glass size specifications:

Maximum processing size: 2440 mm * 3500mm

Minimum processing size: 200 mm * 200 mm

Aluminum spacer specifics: 6 mm, 9 mm, 12 mm, 16 mm

Glass thickness: 3 mm to 19 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q: What is the material of the protective film in the middle of the glass

- Tempered glass film with the raw materials are generally Japan's Asahi pin and domestic Los glass, The production process is: 1: open material, the whole glass is cut into larger than the size of 0.6mm small pieces. 2: CNC carved, will open a good piece of gold with steel sand grinding head down, drilling (or slot), CNC carved after the glass was formed 3, flat grinding, mainly dealing with open materials and CNC caused by surface scratches. 4: cleaning, with ultrasonic cleaning machine will be washed, while the glass drying. 5: steel, with potassium acid to strengthen the glass, so that the glass stress, strength, resistance to meet certain requirements. 6: cleaning: the tempered glass into the ultrasonic cleaning. 7: posted AB glue 8: Packaging finished product

- Q: Automotive glass insulation film paste technology

- The most basic tools are roasted guns, watering cans, foil special agent (or detergent water), water scraper, paste scraper, deerskin, Huju, a knife, each model is not the same paste method is not the same , But there is a common point of glass must be cleaned, preferably in the clean film between the operation.

- Q: What is the difference between tempered glass and ordinary glass?

- Can be affixed to the glass on the super-architectural glass insulation film, thermal explosion-proof UV Nantong super-film 1 3386 2831 Ultra-film building insulation film and decorative glass film has become the new darling of home decoration. Many families prefer this new energy-saving film, because it has excellent energy efficiency. Hot summer, super-film building insulation film and glass insulation film can block 80% of the sun's heat, adhere to the indoor relatively cool, reduce the use of air conditioning and other refrigeration and tempering facilities, saving electricity costs, reduce energy consumption. Practice has proved that the installation of building insulation film and glass insulation film family, summer, even the power outage period can also have a relatively comfortable living environment

- Q: i have an important eco friendly house project 2 do so i need some answers!!!! if u could also post some sites that wld b gr8!!

- I okorder Go to his projects section and take a look as he has many links within his site and external as well. The basic principles of passive solar can be applied anywhere. If you are looking for construction plans and measured drawings- don't. There is too much variation in the windows themselves. You have to have some basic construction skills and some basic design sense to make it really work because those cariations lead to gaps that need filling in, and a means of supporting things. One hint though. If you make a small greenhouse, longer in the east/west direction is best with a low ceiling/roofline, and no narrower than about 8 feet. For heat storage you can use rock, but you will likely have better luck with 55 gallon food grade poly barrels filled with saturated salt water. Start with a dark colored plastic and paint them flat black. Also only fill them about 3/4 full. They will be heavy so place them in their final spot first. Insulate the space, 1 inch foam has respectable performance, add a vapor barrier, and add aluminum foil as radient barrier on the walls as the very inside layer to reflect light to the back side of your heat storage. On the roof, put the foil between the foam and the roof deck. It does work very well. Even in subzero farenheit temps. As long as you have sunlight, it will stay above freezing, otherwise a small 300 watt heater is adequate with 2 60 watt incandescent bulbs to keep it above freezing on the very coldest days.

- Q: Now many people say that architectural glass film can be energy-saving, it is how to save energy in the end? Its energy-saving principles and energy-saving parameters how to quantify?

- Insulating glass: insulating glass is made of two or more glass with aluminum hollow frame frame, sealed with cement or welding, the formation of free space in the middle, can be filled with dry air or inert gas, the heat transfer coefficient U than the single layer Glass is small, good insulation properties, but its shading coefficient SC reduced very little, the solar radiation heat reflex improved little.

- Q: Architectural glass film is generally used to brand which is more ah

- According to the actual situation of the correct choice of architectural glass film, OKorder Chang Bao construction staff engaged in architectural glass film for several years, very good

- Q: China's largest glass deep processing enterprises which

- China 's largest glass deep - processing enterprises Taiwan Glass Group, China' s largest glass of the original film, architectural glass company.

- Q: Is there really a decelerating glass?

- The so-called slow-down glass is the use of the glass surface of the lens effect to reduce the visual sense of speed, so that people feel the speed reduced. The front windshield of the car uses this principle to reduce the deformation of both sides of the scene, reducing the visual displacement of the lateral scene, and the front of the scene is basically direct access, giving the impression that both sides of the scene moving slower.

- Q: So in developing apartments buildings what is the best material to use for the building. Like glass,steel ?etc?

- You mean for building apartment buildings? It varies but probably is brick or block. Go look at a few apartment buildings in the same city and whatever they are made of is probably the right stuff to use.

Send your message to us

A variety of colors of insulating glass 8mm+12A+6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords