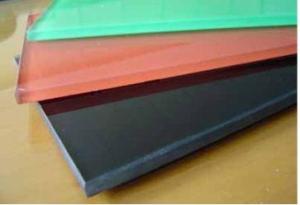

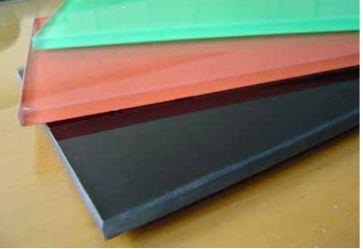

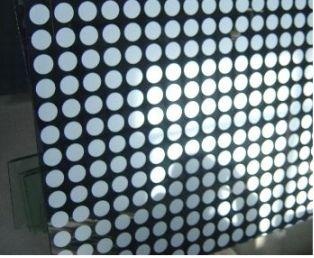

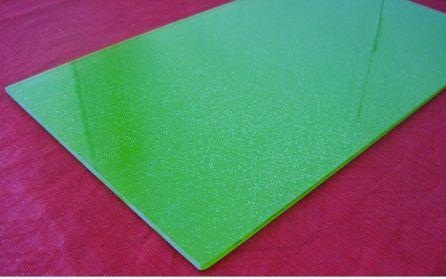

A variety of colors Glaze Reinforced Glass 6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions. Maximum processing size: 2500 mm * 8000 mm Minimum processing size: 200 mm * 300 mm The range of glass thickness: 6.38mm to 50 mm Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass. Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively. Laminated glass A. The selection of suitable float glass pane in storage Access to the next process after the quality inspection of float glass B. The measurements of glass to be cut as customized C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection D. Cleaning by deionized water

Access to the next stage after cleaning the glass E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass F. Cleaning by deionized water Access to the next stage after cleaning the glass G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling I. Inspection during the production process J. Vacuumizing treatment in autoclave

Inspection during the production process K. For subsequent processing and Packaging L. Leading Time:10 days for an average area of 1000 square meters tempered glass M. Trade terms: FOB and CIF. N. Payment Terms: By TT, 30% deposit to start producing, full amount balance paid before delivery. O. Loading and transport |

- Q: What is this wall of glass building material called?

- Architectural glass: Humans learn to use glass has been a thousand years of history, but more than 1,000 years, as the development of architectural glass material is relatively slow. With the development of modern science and technology and glass technology and the improvement of people's living standard, the function of architectural glass is no longer just to meet the lighting requirements, but to have to adjust the light, thermal insulation, security (bulletproof, anti-theft, fire Radiation, anti-electromagnetic interference), art decoration and other characteristics. With the continuous development of demand, glass molding and processing technology has also been a new development. Now, new technologies such as interlayer, tempered, ion exchange, glazed decoration, chemical thermal decomposition and cathodic sputtering have been developed to increase the amount of glass in the building and become the third largest building behind cement and steel material.

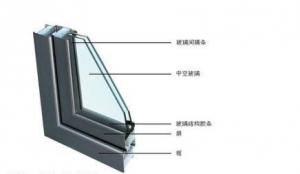

- Q: Sound insulation glass how much money a square

- According to the level of external noise, using our different sound insulation glass combination program, the general indoor can achieve the highest national quiet standard (0 level noise standard). In a large number of practical installation and application process, different degrees of outdoor noise by our professional staff of the measurement, analysis, judgment, using the most appropriate combination of sound insulation solutions, can reach 40 dB below, and some areas can even reach 30- 33 dB, the villa's basement is generally 28-32 dB.

- Q: Lanzhou Huazhong hollow glass factory where

- I was in Chengdu, Sichuan State-level economic and technological development zone of glass deep processing enterprises, in our park also Huacao building materials, and its enterprises mainly engaged in the production of steel profiles and sales, but also set up a steel doors and windows factory, including products, there are insulating glass Building glass supporting sales.

- Q: I want to build a SMALL glass furnace. I'm not working with glass as a business or even as an artist (yet!!!) I want to teach myself to blow glass as a weekend hobby. I've researched the subject extensively and the more I do, the more I want to learn. Yes, I've looked into getting lessons from a professional in my area, it just isn't feasible for me.I can weld (several types), I'm good with electronics (both use and construction thereof) and I have access to all of the tools I could ever need and I can get parts as easy as that.Thank you so much.

- Lindsay okorder / You'll probably find more than you're looking for. It's an awesome resource.

- Q: This is either a milling interpretive center or some sort of museum or gallery. Its shell is very old and decayed but they put a new glass and steel building inside it. The most popular photo is a view from the river in the evening

- Can you be more precise? Have you any idea where this mill is? In the United Kingdom, or in the United States, or somewhere else? The first thing that comes to my mind is the Louvre museum, in France, but I don't think you're talking about that. There is also the Crystal Palace, which used to be in Hyde Park, London. It was first built for the 1851 World Fair. I suggest you visit the Wikipedia article for a few pictures.

- Q: What are the types of architectural glass materials?

- 【classification】: 1. Window glass: Window with flat glass, also known as plain glass or glass, referred to as glass, is not polished flat glass. Mainly used for building doors and windows, walls, outdoor decoration, play light, heat insulation, sound insulation, wind and protection role, can also be used for shop counters, windows and some means of transport (cars, Doors and windows. Window with the thickness of flat glass generally 2,3,4,5,6 mm five, of which 2 ~ 3mm thick, commonly used in civil construction, 4 ~ 6mm thick, mainly for industrial and high-rise buildings. 2. Polished glass: polished glass, said mirror glass or white glass, polished polished flat glass, single-sided polished and double-sided polished two, polished glass is to eliminate the glass containing Glass and other defects. Polished glass surface smooth and shiny, from any direction perspective or reflection of the scene are not deformed, the thickness is generally 5 ~ 6mm, size can be produced according to need. Commonly used to install large high-level doors and windows, windows or mirror.

- Q: What is Article 20 of the Regulations on Safety Management of Building Glass?

- Four of the "building safety glass management regulations" (development and operation [2003] 2116) only 14, is not the twelfth ah? Article 12 Penalties ??(1) The safety glass production enterprise shall bear the corresponding legal responsibility for the serious economic loss or personal injury or death caused by the quality of the safety glass itself. The quality supervision department shall supervise and inspect the quality of its products and, if it fails to meet the quality requirements, It shall impose penalties on it, and the compulsory certification body shall revoke its certification certificate in accordance with the relevant provisions. According to the relevant provisions of the punishment, the certification body should bear the relevant legal responsibility. ??(2) The sales unit shall bear the corresponding legal responsibility for the unit that sells the unqualified safety glass in violation of these Provisions and the major economic loss or personal injury or death caused by the products it sells. ??(3) Any trade contract involving the import of unqualified safety glass in violation of these Provisions shall be subject to corresponding legal liability for causing significant losses or personal injury or death caused by the imported products. ??(4) The construction, design, construction and supervision units that violate these Provisions shall be punished by the construction administrative department in accordance with the relevant provisions. The unit that sells the unqualified safety glass in violation of the provisions shall be investigated and dealt with by the administrative department for industry and commerce according to law.

- Q: So in developing apartments buildings what is the best material to use for the building. Like glass,steel ?etc?

- You mean for building apartment buildings? It varies but probably is brick or block. Go look at a few apartment buildings in the same city and whatever they are made of is probably the right stuff to use.

- Q: Curtains can not pull the first ten centimeters, glass cover, what way to cover

- If the track is not the end can be considered for one, very economical

Send your message to us

A variety of colors Glaze Reinforced Glass 6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords