Curved Polymer Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000 Kgs kg

- Supply Capability:

- 100000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

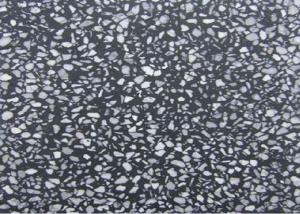

Commodity: Industrial PP Fiber for Concrete, Engineering Fiber

PP fiber,also called Polypropylene PP Fiber, Polymer Fiber,it is manufactured by mixing, spinning, stretching and cutting the combination of modified base and polypropylene paring, used as the project fiber for concrete and mortar. It can decrease cracks in concrete's early stage.

Property of Curved Polymer Fiber:

| Polypropylene monofilament fiber technical | ||

| Item | Product name | PP fiber |

| 1 | Material | 100% polypropylene |

| 2 | Cut length | From 3mm to 120mm |

| 3 | density | 0.91g/cm³ |

| 4 | Diameter | 20 micron to 40micron |

| 5 | Strength | 400-600Mpa |

| 6 | elongation at break | 30%-40% |

| 7 | melting point | 170°C |

| 8 | ignition point | 590°C |

| 9 | Oil point | lower than 1% |

| 10 | Water-hygroscopicity | No |

Advantages of Curved Polymer Fiber:

Good dispersancy, better grip

Random dispersal, subordination reinforced

Physically-added tendon, anti-crack and high reinforcement

Diamagnestism and antirust, corrosion protection and alkali resistant

Innocuous and odorless, safe

Simple operation, more economic and dependable

Function of Curved Polymer Fiber:

Anti-crack

Increasing seepage-proof performance

Anti-concussion and anti-wear performance

Increasing shock proof

Cold-resistant property

Enhance the property of toughness and ductility

Fire resistance and anti-detonation quality

Preventing or reducing the major reinforcing steel bar from being eroded

Reducing rebound of jetting concrete

Application:

Industry and Civil Architecture

Main body of road, bridge

Water conservancy project

Package:

A: Packing in plastic bags, plastics bags to be put into waterproof bags, and then waterproof bags to be put into container, totally 8 tons in 1x20'FCL

B: Packing in fusible paper bags, paper bags to be put into cartons, and then cartons to be put into pallet, pallets to be put into container, totally 6 tons in 1x20'FCL.

- Q: why are cement factories important for the economics in uae?

- cement is one of many things that are necessary for oil production and all construction.

- Q: i want to put some cement in my backyard for a basketball court, is it really expensive, and about how much is it per ft.?

- If you hire a concrete contractor it is about $8.50 a square foot poured and finished. I think that is what you were look for.

- Q: Please let me know the top four quality brands of cement that may be used in building /house construction.

- To answer your question it would be necessary to know in what area of the US you are located. The top four brands in the Mid West may not even be available on the east or west coasts. Although cement plants may be large in an area they quite possibly are not nation wide suppliers. As in business and housing most important is location, location, location. Check with a local concrete supplier and they will be able to provide an answer to your question. As a result of having to produce quality and consistent concrete the concrete suppliers typically use the top quality cement available in the area. But they usually limit their brand selection to one supplier, otherwise they would experience variations in quality of their concrete solely a result of the cement supplier. I provide to previous so you are not disappointed in only getting one quality brand in your area.

- Q: what are the types of cement availabale and give their applications?

- Do you mean cement or concrete? Cement is just sand and lime; concrete has a stone mix added. Cement can be used as a mortar to bind stone and brick, and as a stucco surface for EFIS material, brick, concrete block etc. They can differ in the mix ratio and color. Concrete varies basically by color, strength, and drying time. It's used for sidewalks, high speed roadways, foundations, concrete blocks, retaining walls, building structure, floor slabs, steps, a base for built-up roofs, roadway curb and gutter, storm water drainage basins and inlet structures, bridges, bridge aprons, swimming pools, cast sculptures, kitchen counter tops, dams, and piers for bridges and off-shore drilling platforms,

- Q: I'm really into polymer clay charms making. I want to make flexible molds, but i don't want to spend $$ on buying the mold putty and stuff. I tried silicone once but i don't like it. Im wondering if you make molds using rubber cement, would it work?

- No, it wouldn't. Simply because rubber cement truly dries by evaporation. Other mold making materials cure, which is different. You'd need to coat your model many, many times and let it dry thoroughly in between, and even then it's not made for the job. It's awfully soft. Maybe it could be done, but in the end it would be inferior and probably not any cheaper. One coat of cement will be like a sheet of paper, in thickness, after it dries. Maybe less. Spring for the molding compounds and make your life easy.

- Q: the house is from 1959. Before I bought it the owners re-landscaped without any consideration for water flow thus causing the basement to have seepage through the walls. I fixed the water flow issue (1.5 years dry) but now I have painted cement walls that have paint pushed out/peeling with a few visible cracks and wonderful mineral deposition. I really don't want to spend the time with the metal wire brush to strip the paint off so I would like to just use hydraulic cement over the whole wall and then use a water sealing paint over the top. Is this a good idea? other suggestions?

- That sounds more time consuming than just scraping off the peeling paint..... Here's 1 problem w/your approach, latex paint dries so fast that it actually creates a vacuum effect in doing so, which means that as it dries it'll pull off the surface anything that's not firmly attached, which is why prep work's so important to longevity. You won't immediately notice this happening, but w/the passage of time you'll be back to the peeling wall in spades. I've never heard of skim-coating w/hydraulic cement, but I've done plenty of patching plaster walls w/plaster of paris, what immediately comes to mind are the inherent problems w/working in a medium that sets up so quickly, I can't imagine how you'd get a whole wall covered looking even satisfactory (but I'm pretty picky, I figure when people are paying me I'm obliged to do a better job than they could've) w/out going insane in the process. I learned the trick to plaster, but I don't know the chemistry of hydraulic cement well enough to find a retardant for it. Anyways, I know prep-work sucks, but often it's just easiest to do it get it over with (start w/a stiff putty knife, by the way) rather than inventing a new process having to deal w/a long string of learning curves as you go. The first question that came to mind w/your question is have you ever skim-coated anything before so that you'd have even a vague idea of what you're getting yourself into potentially, but if you must create, than by all means go forth!

- Q: how is cement prepaed? what are the uses and different types of cement?

- I've been in exactly the same situation. We live on the edge of nowhere and can't get delivered concrete. We poured our greenhouse floor, using Portland premix cement and a mixer. Our mixer is slightly smaller than yours. We used extra water in the mix so it would stay workable longer. Bad idea! The floor did fine until the first winter. It then split, chipped cracked and, well, you get the picture. We ended up redoing it. The second time we divided the floor into three sections. Each section had its own small 3/8 rebar web placed 2 above ground in a 4 floor. We supported the web by driving 10 pieces of 3/8 rebar into the ground and wire to hold the web to them. Lastly, on the sides where the adjoining sections would go, we used 1 x 6 pieces of redwood. We drilled them and ran rebar through to the web – leaving 2' sticking out for attaching the new sections. That piece sticking out was attached to the next section's rebar web. It has been there for several years now, and has no cracks at all. Our temperatures range from 105°F in summer to -40°F in winter. I put a link in to show how to determine how many cubic yards of concrete you'll need. Good luck!

- Q: Preferably in a bright white color.

- Glue or concrete?

- Q: I am renovating a house and need to remove some cement/plaster. I do not want to break it off or saw it away. I have tried vinegar, hot water, olive oil. Is there any way to soften cement/plaster that has set?

- once it has set you will have to either break it or maybe try some corrosive chemicals such as hydrochloric acid im sorry that im currently under a mind blank so thats all i can think of but there are commercial liquids that work as long as it hasnt been there for more than 2-3 days

- Q: I am wanting to add a cement patio on to my house and in order to build a $6000 patio, I have to pay a $5000 road bond to the village does that make sense

- Bonds are not insurance. What they are asking for is that you provide a bond to promise to pay up to $5000.00 if the cement truck damages the roads it is travelling on. You go to a bonding company (sometimes your insurance company will provide the bond), pay them a fee for providing the bond and have the work done. If the truck damages a road, the bonding company will pay out up to $5000.00 for the damage, then you will have to reimburse the bonding company for it's outlay. Bonds are NOT insurance.

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Curved Polymer Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000 Kgs kg

- Supply Capability:

- 100000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords