Coated AR Glassfibre Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Coated Alkali resistant Fiberglass Mesh Cloth has passed ISO9001:2000 CE ITB Certificate.It's ideal construction material.

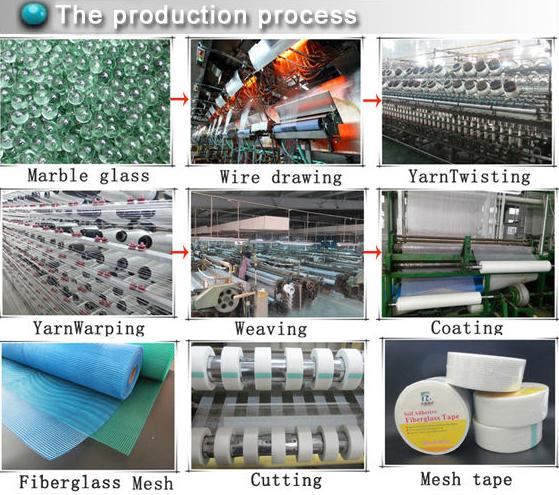

Fiberglass Mesh is woven by fiberglass yarn, then alkaline-resistent latex coated. It owns great alkaline-resistent and high strength. As a perfect engineering material in construction, it is widely used to reinforce cement, stone, wall materials, roofing, gypsum and so on.

Fiberglass Mesh Specification:

Mesh Size | Density | Width | Length per Roll | Color |

(mm) | (gr/m2) | (mm) | (m) |

|

2*2 | 30-600 | 100-2000 | 10-1000 | All Colors |

2.5*2.5 | ||||

4*4 | ||||

5*5 | ||||

4*5 | ||||

5*6 | ||||

10*10 |

Specifications can be made as per customers requirements.

High Quality

(1) Coating glue: our coating glue is produced by Germany BASF which can keep more than 70% after days NaoH test.

(2) The fiberglass yarn is manufactured by ourselves. We have 60 Platinum Crutinum to produce glass fiber, it owns 20% more strength and beautiful surface than normal fiberglass yarn.

Package:

Each Fiberglass Mesh Roll is put into PVC bag or Shrink Bag, and then put into Carton or Pallet.

Payment:

T/T 30% in advance, T/T 70% after loading goods on board.

Your enquiry is warmly welcomed and treated with more attations.

- Q: i know there is a certain height from where when you fall into the water you can no longer survive becuase its like hitting cement. how far is that?

- i think it might be around 60 or 70 feet..

- Q: For my graphics class**Do I simply apply an even coat to one of the pieces I want to glue, wait for it to dry, then apply it?I've been looking for videos. I don't want to mess this up. Also, how do I use this particular tool to smoothen the paper?

- When I've used rubber cement, I've applied a coat to both surfaces to be glued, let it dry until tacky ( when it no longer looks shiny and is slightly sticky to the touch) and then put them together. Putting them together is the tricky part: the rubber cement sticks right away, and it's hard to re-place whatever you're trying to glue, so you have to place the pieces correctly on the first try. I've never used a tool like that to smooth paper (correction: I've never smoothed paper, but when I've used a tool like that I've used it to make neat folds). I would guess the unpointed end, but past that I have no idea. Sorry. If you use the rubber cement properly you can just smooth the paper with your fingers as you glue it down, and you shouldn't need to use a tool at all. Good luck!

- Q: I am putting tile on the wall in my bathroom (not in the shower), do i have to put cement board behind it?or can i just leave the drywall that is already there?

- I would highly recommend doing it right and using cement board. Try to avoid using any type of plywood for a substrate to attach the tile too. Ceramic tiles can be installed directly on drywall, plaster, or if they are in moist areas, onto green drywall or even better cement backer board. Cement backer board is actually made from a fiberglass mesh and Portland cement, so moisture won't bother it at all. It is available in 1/2 and 5/8-inch thick sheets (similar to drywall), and is usually sold in 32 or 36-inch wide panels 5 or 8 feet long. for other information check my source site

- Q: When i buy it from a cement supply house they charge me sales tax but when i buy it from home depot or lowes they dont. My accountant told me to be careful since i am responsible for paying my taxes.

- Yes. Everything gets taxed. Are you sure Home Depot or Lowes don't charge you tax at the register? That's odd if they don't.

- Q: We are buying a house that already has ceramic tile floors (18 x 18 tiles) We would like to lay travertine instead. MY question is, Will the floor already have cement board underneath the existing ceramic tile since it was done professionally 10 years ago? Also the house is 2100 sq ft roughly, how much should just the tile and supplies cost? We already have a tile guy n mind but will buy all the supplies ourselves. Lastly, pros and cons of travertine?

- One poster is right you can t really be able to tell just by looking. If there is forced air heat, lift a register and look whats between the tile and subfloor. Over the years I have seen it all .. There are so many ways to install tile , some proper and some not.. I ve seen many types and thicknesses of plywood., cement board(s) properly and improperly used and even many good installers will do a mud job. A proper mud job is the absolute best way to do tile.. Sealer will cost around 80/100 $ a gallon.And you ll need several gallons for that amount.. Have your installer look at the job. A good installer will be able to determine what was used.. Travertine is a beautifull stone and when properly sealed and maintained will last a life time. This type of stone will start at 5$ a s/f and go up from there.Thinsets go for about 13/15$ a bag and cover about 70/80 s/f per bag. Cement board is 10$ a sheet and covers only 15 s/f per sheet. Grout is about 10$ a bag but tile thickness will determine how many you need.. If you have a slab flooring no extra subflooring will be needed. Your tile guy will give you the exact amounts you will need. Ask for a quanity discount , you d better get it for that anount of material. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: I need to glue a small plastic piece to another plastic piece, will the cement work? What are the steps in gluing and making sure the glue holds?

- Review from CoolTools: All-purpose cobbler's glue 12-29-10 Barge Cement My dad used Barge Cement for various things on his boat since I was a child. It is actually a cobbler's glue, but it works with just about anything. It is a bit hard to find and there are inferior products touting the same uses (less toxic), but nothing is as good as Barge. I mainly use it for leather - hems, applique, etc., but I have also used it to glue a flat-bottomed birdhouse onto a flat-cut tree trunk, to tack down wallpaper seams that have lifted, to hold wood seams prior to screws being put in place, to secure a rubber foot to a chair leg, or the chair leg to the seat when wood glue has failed - just about anything you wouldn't use Crazy Glue for. In a pinch, Barge can fill the need of many sewing jobs (not buttons, though).

- Q: What is water/cement ratio?

- some of one and a bit of the other

- Q: how long does it take for dental cement to dry?

- A minute or so. Edit: Well next time be specific. Bracket cement is hardened with the use of a curing light. (blue light that the orthodontist will hold over the teeth.) Each individual tooth is processed using this light. Each tooth takes about 3-5 minutes. After the brackets are on and dried, they put the wires in.

- Q: I want to stain my cement/concrete patio around my pool. What is the best stain to use. I don't want to have to keep redoing it every year.

- you don't stain cement you paint it!! that is why you are having to redo it every year. cement does not absorb things paint is thicker and will stick to the cement.

- Q: .. blems?The house we are considering buying is about $125,000.00 It has 4 bdrms 1 bath built in 1910. 2,330 sqf. The basement has crumbling cement in the half and dark paneling in the other half. Those are the only problems with the house. are these doable to fix? tear down the cement and re cement, is it expensive, or painting or putting dry wall over the paneling. what do you think?

- if the concrete basement walls are not structurally sound, repairs can get really expensive really fast. on the other hand, if the surface is spalling (flaking off small amounts) and the concrete is still structurally sound, I believe there are remedies that can be effective. as for the paneling, that is relatively easy. sheetrock looks better if a professional does it than a first time DIY person, but with patience a DIY can do a reasonable job of it. you can also paint paneling, but if it's a slick finish, then you will need to do some prep work. clean it well, and then scuff the surface with fine sandpaper, or use a high dollar primer, or both, and then the paint should stay on reasonably well.

Send your message to us

Coated AR Glassfibre Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords