High Alumina Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

65% Al2O3 Min High Alumina Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

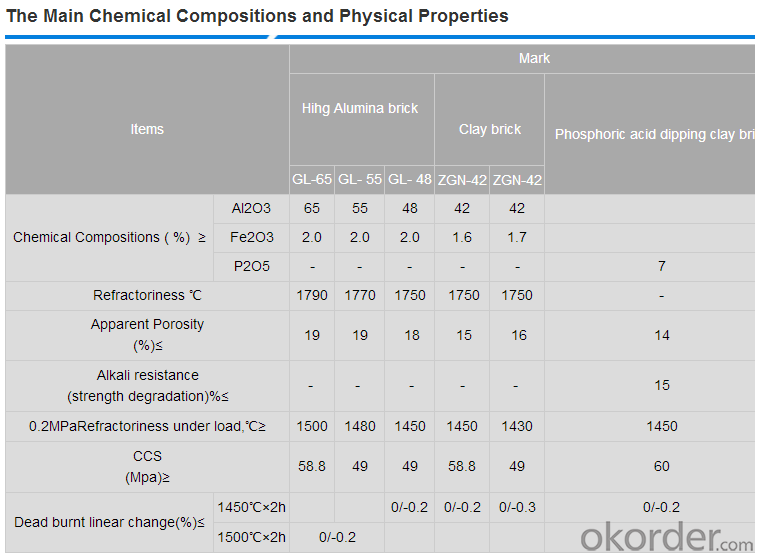

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

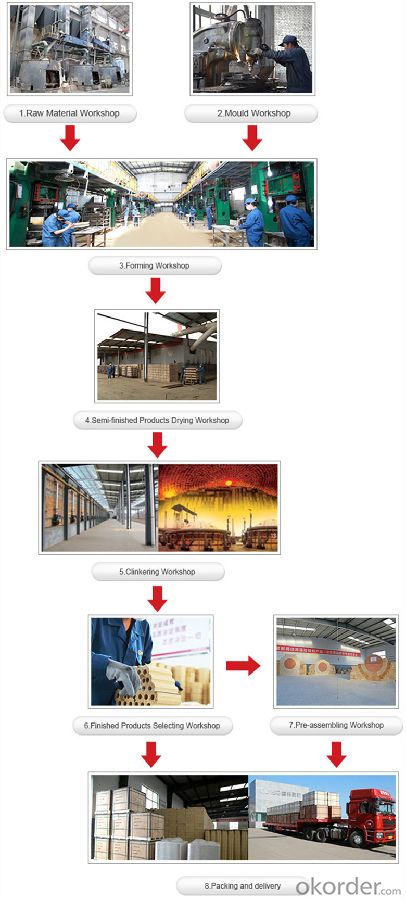

Produce Processing

- Q: What are the different types of insulating fire bricks available in the market?

- There are several different types of insulating fire bricks available in the market. Some of the most common types include: 1. Lightweight Fire Bricks: These bricks are made from lightweight and porous materials, such as expanded clay, vermiculite, or perlite. They offer excellent insulation properties and are commonly used in applications where weight is a concern, such as for lining the walls of kilns or furnaces. 2. Ceramic Fiber Bricks: These bricks are made from ceramic fibers that are compressed and formed into bricks. They have high insulating properties, low thermal conductivity, and can withstand high temperatures. Ceramic fiber bricks are often used in applications that require high-temperature insulation, such as in the construction of industrial furnaces or ovens. 3. Calcium Silicate Bricks: These bricks are made from a combination of lime, silica, and reinforcing fibers. They have good thermal insulation properties and are resistant to thermal shock. Calcium silicate bricks are commonly used in applications where high-temperature insulation is required, such as in the construction of boilers or incinerators. 4. Magnesia Bricks: These bricks are made from magnesium oxide, which is a highly refractory material. They have excellent thermal insulation properties and can withstand extremely high temperatures. Magnesia bricks are often used in applications that require insulation in high-temperature environments, such as in the lining of steel-making furnaces or glass melting tanks. 5. Vermiculite Bricks: These bricks are made from expanded vermiculite, which is a naturally occurring mineral. They have good insulation properties, low thermal conductivity, and are resistant to high temperatures. Vermiculite bricks are commonly used in applications that require lightweight insulation, such as in the construction of chimneys or fireplace surrounds. Overall, the choice of insulating fire bricks depends on the specific requirements of the application, such as the desired level of insulation, temperature resistance, and weight considerations.

- Q: Is it possible to repair damaged insulating fire bricks?

- Repairing damaged insulating fire bricks is indeed possible, and the method required will depend on the extent and type of damage. For minor cracks or chips, one can utilize a refractory mortar that is specifically designed to endure high temperatures and create a strong bond. This mortar can effectively fill in the gaps and restore the brick's integrity. However, if a larger section of the brick is damaged or completely missing, it may be necessary to replace the entire brick. In such a scenario, the damaged brick must be cautiously removed, and a new one can be installed with the appropriate refractory mortar. It is crucial to ensure that the repaired or replaced brick adheres to the original specifications and quality to guarantee proper insulation and structural integrity. It is highly recommended to seek advice from a professional or carefully follow the manufacturer's guidelines for the specific repair process.

- Q: Can insulating fire bricks be used in the construction of smelting furnaces?

- Smelting furnaces can indeed utilize insulating fire bricks in their construction. These bricks have been specifically crafted to endure extreme temperatures and offer exceptional insulation, rendering them an impeccable choice for smelting furnaces. Their low thermal conductivity aids in minimizing heat dissipation and upholding a steady temperature within the furnace. Moreover, these bricks are lightweight, which facilitates their handling and installation. All in all, incorporating insulating fire bricks in the construction of smelting furnaces can enhance energy efficiency, diminish operational expenses, and elevate the overall furnace performance.

- Q: Can insulating fire bricks be used in the construction of incineration kilns?

- Yes, insulating fire bricks can be used in the construction of incineration kilns. These bricks have excellent thermal insulation properties, which helps in maintaining high temperatures inside the kiln while minimizing heat loss to the surroundings. This is crucial in incineration processes where high temperatures are required to efficiently burn waste materials. Additionally, insulating fire bricks are resistant to thermal shock and can withstand the extreme temperatures and harsh conditions typically found in incineration kilns.

- Q: Are insulating fire bricks suitable for use in the construction of drying ovens?

- Yes, insulating fire bricks are suitable for use in the construction of drying ovens. They have excellent thermal insulation properties, which helps to retain heat and prevent heat loss during the drying process. Additionally, insulating fire bricks can withstand high temperatures and have good resistance to thermal shocks, making them a reliable choice for drying oven construction.

- Q: Are insulating fire bricks resistant to vibrations?

- Yes, insulating fire bricks are generally resistant to vibrations. They are designed to withstand high temperatures and physical stress, making them suitable for applications where vibrations may occur, such as in furnaces or kilns. However, the level of vibration resistance may vary depending on the specific composition and quality of the insulating fire bricks.

- Q: Do insulating fire bricks emit any toxic fumes when heated?

- No, insulating fire bricks do not emit any toxic fumes when heated. They are designed to withstand high temperatures without releasing any harmful gases or substances.

- Q: Are insulating fire bricks resistant to insects and rodents?

- Yes, insulating fire bricks are generally resistant to insects and rodents due to their dense and solid construction, which makes it difficult for pests to penetrate or damage them.

- Q: Can insulating fire bricks be used in glass furnaces?

- Yes, insulating fire bricks can be used in glass furnaces. They are commonly used to line the walls and roofs of glass furnaces to reduce heat loss, improve energy efficiency, and provide thermal insulation.

- Q: How do insulating fire bricks affect the overall energy savings of a structure?

- The overall energy savings of a structure can be greatly enhanced by using insulating fire bricks. These specialized bricks are designed with low thermal conductivity, effectively preventing heat transfer. By incorporating insulating fire bricks into the construction, heat loss through walls, floors, and ceilings is significantly reduced. One of the main ways these bricks contribute to energy savings is by improving the structure's insulation. With their high resistance to heat flow, insulating fire bricks help maintain a consistent indoor temperature. This reduces the need for artificial heating or cooling, as the bricks keep the interior warmer in colder months and cooler in hotter months. As a result, reliance on HVAC systems is reduced, resulting in substantial energy savings. Furthermore, insulating fire bricks also minimize thermal bridging, which occurs when materials with high thermal conductivity create pathways for heat to escape or enter the building. By using bricks with low thermal conductivity, these pathways are disrupted, greatly reducing heat transfer. This ensures that the building's insulation remains intact and minimizes energy loss. In addition, insulating fire bricks improve the efficiency of heating appliances. By lining the interior of fireplaces, furnaces, or kilns with these bricks, the heat generated is efficiently contained, leading to better heat distribution and reduced waste. This means less energy is required to achieve desired heating levels, resulting in increased energy savings. Overall, insulating fire bricks have a significant impact on energy savings for a structure. They enhance insulation, minimize thermal bridging, and improve the efficiency of heating appliances. By reducing heat loss and optimizing heating and cooling systems, these bricks greatly decrease energy consumption, leading to long-term cost savings and a more sustainable building.

Send your message to us

High Alumina Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords