Insulating Fire Brick - Refractory High Alumina Thermal Insulating Fire Brick 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Refractory High Alumina Thermal Insulating Fire Brick 2015

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | international index | Al2O3 Content (%): | ≥48 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | LG-1.0 | Brand Name: | |

| Sample: | Free | Fe2O3 %: | ≤2 | Bulk Density, g/cm3: | ≤1.0 g/cm3 |

| Cold crushing strength(Mpa): | ≥3.9 | temp linear change on reheating: | 1400 | Thermal conductivity /W.(m.k)-1: | ≤0.5 |

| size: | 230mm*114mm*65/75mm | HS code: | 6902200 |

Packaging & Delivery

| Packaging Details: | Packed on wooden pallets, with water-proof cover, all measurements of each case is 1050mm*1050mm*1050mm. We will pack the goods according to your requirement. |

| Delivery Detail: | 10~30 days after receiving your payment |

refractory lightweight high alumina thermal insulating fire brick

Product Description

Refractory lightweight high alumina thermal insulating fire brick is made out of a naturally-occurring material known as bauxite. This material includes aluminum hydroxide, which is what gives the bricks such great warmth resistance. The bricks also include kaolinitic clays, which are roasted to create an unique combination including mullite and also synthetic alumina. This is where the name “high alumina” stems from.

Features

1.High-temperature endurable .

2.Good thermal shock resistance .

3.High cold crushing strength.

4.Good resistance to abrasion and corrosion.

5.Good thermal spalling resistance.

6.High mechanical strength.

7.Good volume stability at high temperature.

Application

1.General use in heat containment unit form temperature 1500-2000°C.

2.Resistant to highest temperature for steelmaking operations such as ladle applications, sidewall, roofs, burner blocks, anchor brick for reheating furnaces and many other areas.

3.transition and cooling zones of rotary cement kilns, lime kilns , etc.

4.lower sidewall and bottom of aluminum refining,melting furnaces ,etc.

Technical Data

Description of parameters |

Index of high alumina lightweight fire brick | ||||||

LG- 1.0 | LG-0.9 | LG-0.8 | LG-0.7 | LG-0.6 | LG-0.5 | LG-0.4 | |

AL2O3 % | ≥48 | ||||||

Fe2O3 % | ≤2.0 | ||||||

Bulk Density, g/cm3 | ≤1.0 | ≤0.9 | ≤0.8 | ≤0.7 | ≤0.6 | ≤0.5 | ≤0.4 |

Cold Crushing Strength MPa | ≥3.9 | ≥3.4 | ≥2.9 | ≥2.5 | ≥2.0 | ≥1.5 | ≥0.8 |

Test temp linear change within 2%on reheating | 1400 | 1400 | 1400 | 1350 | 1350 | 1250 | 1250 |

Thermal conductivity /W.(m.k)-1 | ≤0.5 | ≤0.45 | ≤0.35 | ≤0.35 | ≤0.30 | ≤0.25 | ≤0.20 |

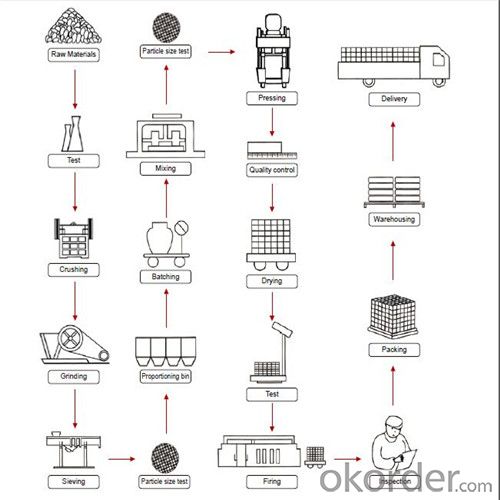

Packaging & Shipping

1. Strong packing will protect the goods from any possible damage during transit.

2. Solid packing and overall stuffing can prevent the cases from vibration and jarring.

3. We must take necessary precaution that the packing can protect the goods from pilferage or rain.

4. l can confirm that we take every possible precaution to ensure that our products reach our customers all over the world in prime conditon.

Our Services

1.We will reply to you immediately, if you have any question.

2.We can provide free samples for you.

3.we have all kinds of fire bricks ,for example,high alumina brick ,fireclay brick, corundum brick, refractory ball, allotypic brick, lightweight brick and so on. We can offer you products of a wide range of specifications.

Why choose us

1.We are professional manufacturer of refractory brick and had been in this line for more than 20 years .

2.Our products quality will be guaranteed . We have our own technical team to test the products before delivery.

3.Competitive prices based on same quality. Guarantee samples quality same as mass production quality.

4.Adhering to the business philosophy "mutual trust, mutual benefit, mutual profit, faith oriented".

5.We can according to your requirements to produce your order and OEM/ODM service is available.

6. Products are inspected through SGS and BV etc and accord with the international standard.

7.Your inquiry related to our products or prices will be replied in a timely manner.

8. We provide the best after sales service.

- Q: What is the typical modulus of rupture of an insulating fire brick?

- The typical modulus of rupture of an insulating fire brick is around 100 psi (pounds per square inch).

- Q: Can insulating fire bricks be used in solar power plants?

- Yes, insulating fire bricks can be used in solar power plants. They are commonly used in the construction of high-temperature equipment such as solar receivers, combustion chambers, and thermal energy storage systems. Insulating fire bricks help to minimize heat loss and maintain high operating temperatures, making them suitable for various applications in solar power plants.

- Q: Are insulating fire bricks resistant to thermal fatigue?

- Yes, insulating fire bricks are generally resistant to thermal fatigue due to their ability to withstand repeated heating and cooling cycles without significant damage or deterioration. Their high thermal shock resistance and low thermal conductivity make them ideal for applications where thermal cycling occurs frequently.

- Q: Are insulating fire bricks easy to cut or shape?

- Yes, insulating fire bricks are relatively easy to cut or shape. They can be cut using basic tools such as a saw or a knife, and they can also be shaped by using a chisel or sandpaper. Their soft and lightweight composition allows for easier manipulation and customization to fit specific requirements.

- Q: Are insulating fire bricks resistant to fire damage?

- Yes, insulating fire bricks are specifically designed to be resistant to fire damage. They are made from special refractory materials that can withstand extremely high temperatures without deforming or losing their insulating properties. Insulating fire bricks have a high melting point and low thermal conductivity, which allows them to effectively insulate against heat transfer and protect against fire damage. They are commonly used in applications where high temperatures and fire exposure are expected, such as in furnaces, kilns, fireplaces, and industrial processes. Overall, insulating fire bricks are reliable and durable materials that provide excellent protection against fire damage.

- Q: Can insulating fire bricks be used for insulation in sewage treatment plants?

- Insulating fire bricks are capable of being utilized for insulation purposes in sewage treatment plants. Specifically designed to endure elevated temperatures and deliver exceptional insulation, these bricks prove to be suitable for deployment in environments characterized by heat and moisture, such as sewage treatment plants. With their low thermal conductivity, they aid in diminishing heat loss and enhancing energy efficiency throughout the treatment procedure. Furthermore, their resistance to chemicals and moisture renders them ideal for enduring the corrosive surroundings typically encountered in sewage treatment plants. Consequently, the usage of insulating fire bricks effectively ensures insulation in sewage treatment plants, thereby aiding in the preservation of optimal operating temperatures and the enhancement of overall efficiency.

- Q: Can insulating fire bricks be used in the construction of smelting furnaces?

- Smelting furnaces can indeed utilize insulating fire bricks in their construction. These bricks have been specifically crafted to endure extreme temperatures and offer exceptional insulation, rendering them an impeccable choice for smelting furnaces. Their low thermal conductivity aids in minimizing heat dissipation and upholding a steady temperature within the furnace. Moreover, these bricks are lightweight, which facilitates their handling and installation. All in all, incorporating insulating fire bricks in the construction of smelting furnaces can enhance energy efficiency, diminish operational expenses, and elevate the overall furnace performance.

- Q: Can insulating fire bricks be used for insulation in heat exchangers?

- Yes, insulating fire bricks can be used for insulation in heat exchangers. Insulating fire bricks have excellent thermal properties, high insulation efficiency, and can withstand high temperatures, making them suitable for heat exchangers where insulation is crucial to minimize heat loss and increase energy efficiency.

- Q: Are insulating fire bricks resistant to sulfur dioxide?

- Insulating fire bricks are generally not resistant to sulfur dioxide. Sulfur dioxide is a highly corrosive gas that can react with the materials used in insulating fire bricks, leading to their degradation and reduced effectiveness. It is important to use refractory materials specifically designed to withstand sulfur dioxide exposure if that is a requirement for the intended application.

- Q: Do insulating fire bricks have a high compressive strength?

- Yes, insulating fire bricks typically have a high compressive strength due to their dense and sturdy composition.

Send your message to us

Insulating Fire Brick - Refractory High Alumina Thermal Insulating Fire Brick 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords