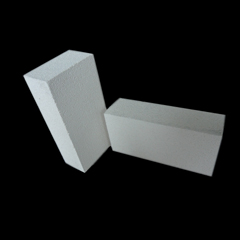

High-Quality Insulating Fire Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description:

lightweight mullite brick is made from high-grade and high purity refractory powders and materials.During the process of production,organic and multiple filling materials are injected according to required proportion.The brick is compressed in vacuum and sintered under high temperature. Category:

LYJM-23A LYJM-23B LYJM-23C

LYJM-26A LYJM-26B LYJM-26C

LYJM-28A LYJM-28B

LYJM-30A LYJM-30B

Features:

Low thermal conductivity and capacity

High purity,low content of impurity

High thermal resistance and could contact fire directly

High strength and resistant to thermal shock

Accurate measurement and incised optionally

Typical applications:

Lining and back lining of various furnaces in the industry of metallurgy,petrochemical,ceramics,machinery and building materials.

For instance:the Cracking Furnace,Conversion Furnace,heating equipment,refining equipment,Hot Blast Stove,Heating Furnace,Even-heating Furnace,Heat-processing Furnace,Resistance Furnace,Tunnel Kiln,Shuttle Kiln,Bell-cover Kiln,Glass-pool Kiln,etc

- Q: Are insulating fire bricks suitable for use in coke ovens?

- Insulating fire bricks are not suitable for use in coke ovens. Coke ovens require bricks that can withstand extremely high temperatures and harsh chemical environments. Insulating fire bricks are designed to provide thermal insulation and are not able to withstand the heat and chemical exposure that occurs in coke ovens. Therefore, it is crucial to use refractory bricks specifically designed for coke ovens, which have high resistance to temperature, chemical attacks, and thermal shock. These refractory bricks are typically made from materials such as silica, alumina, and carbon, which can withstand the harsh conditions inside the coke ovens.

- Q: Are insulating fire bricks suitable for use in chimneys and fireplaces?

- Yes, insulating fire bricks are suitable for use in chimneys and fireplaces. They have excellent thermal insulation properties, which helps to retain heat and prevent the transfer of excessive heat to the surrounding structure. This makes them a safe and efficient choice for lining chimneys and fireplaces, as they can withstand high temperatures and reduce the risk of heat damage.

- Q: Do insulating fire bricks require any special fireproofing treatments?

- There is no need for any special fireproofing treatments for insulating fire bricks. Insulating fire bricks are composed of lightweight materials that possess excellent insulation properties, such as refractory clay or ceramic fibers. These materials possess inherent fire resistance and can endure high temperatures without requiring extra fireproofing treatments. Nevertheless, it is crucial to guarantee the correct installation and utilization of insulating fire bricks in order to enhance their efficiency and lifespan.

- Q: Can insulating fire bricks be used in ladles?

- Yes, insulating fire bricks can be used in ladles. Insulating fire bricks are designed to withstand high temperatures and provide thermal insulation. They are commonly used in applications where there is a need to maintain or control high temperatures, such as in furnaces, kilns, and ladles. Ladles are used for pouring and transferring molten metal or other materials, and the use of insulating fire bricks in ladles helps to minimize heat loss and improve energy efficiency. Additionally, insulating fire bricks can also provide a protective barrier against chemical reactions and erosion caused by the molten materials, making them suitable for ladle applications.

- Q: Can insulating fire bricks be used in the construction of steam generators?

- Yes, insulating fire bricks can be used in the construction of steam generators. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for applications such as steam generators where heat retention is important.

- Q: Are insulating fire bricks resistant to reducing atmospheres?

- Yes, insulating fire bricks are resistant to reducing atmospheres.

- Q: Are insulating fire bricks resistant to gas permeation?

- Generally, insulating fire bricks exhibit resistance to gas permeation. They possess a low porosity design, minimizing open spaces for gas passage. This attribute renders them highly effective in preventing gas permeation. Moreover, insulating fire bricks are commonly constructed from materials like alumina, known for their exceptional resistance to high temperatures and chemical reactions. This further bolsters their resistance to gas permeation. In conclusion, insulating fire bricks are a dependable option for minimizing or preventing gas permeation in various applications.

- Q: Can fly ash brick keep warm?

- Add blocks and have autoclaved fly ash bricks, do not you?

- Q: Can insulating fire bricks be used in ceramic kilns?

- Certainly, ceramic kilns can make use of insulating fire bricks. These bricks are specifically crafted to possess a minimal thermal conductivity, enabling them to better retain heat. Consequently, they prove to be an excellent option for lining the kiln walls, facilitating the conservation and uniform distribution of heat within the kiln chamber. Furthermore, these fire bricks are lightweight and possess exceptional resilience against thermal shock, rendering them highly durable and capable of withstanding the elevated temperatures commonly achieved in ceramic kilns.

- Q: Can insulating fire bricks be used in a refractory lining?

- Indeed, refractory linings can incorporate insulating fire bricks. These bricks are purposefully crafted to offer thermal insulation and minimize heat dissipation in scenarios involving high temperatures. Possessing low thermal conductivity and exceptional insulating properties, they are perfectly suited for use in refractory linings. By curbing heat transfer to the surrounding environment, these bricks contribute to the enhanced energy efficiency of furnaces, kilns, and other industrial applications. Moreover, insulating fire bricks are lightweight, effortlessly installable, and exhibit commendable strength and durability, rendering them a favored selection for refractory linings.

Send your message to us

High-Quality Insulating Fire Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords