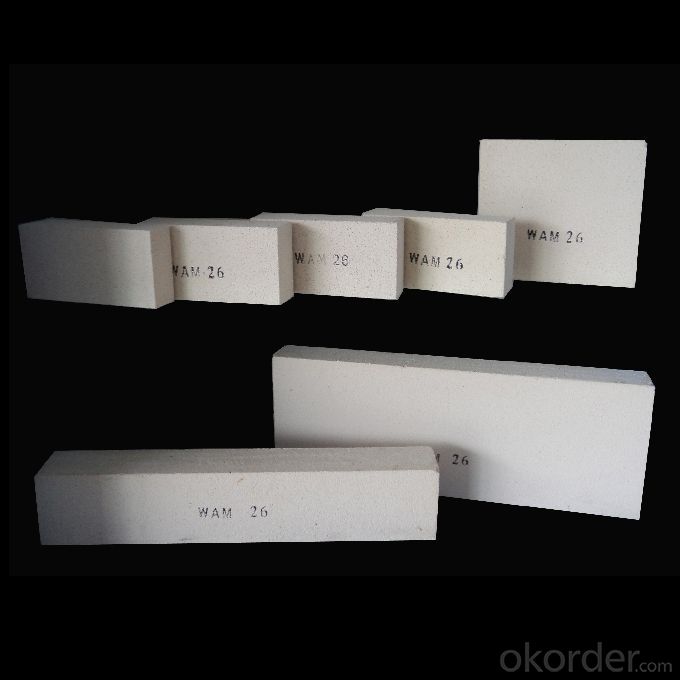

Insulating Fire Brick - Refractory Mulite Insulating Fire Brick GJM25

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Can insulating fire bricks be used for insulation in cement kilns?

- Yes, insulating fire bricks can be used for insulation in cement kilns. Insulating fire bricks are made from lightweight materials with high insulation properties, such as ceramic fibers or expanded clay. These bricks are designed to have low thermal conductivity, meaning they can effectively reduce heat transfer and retain heat within the kiln. Cement kilns operate at very high temperatures, often exceeding 1,400 degrees Celsius (2,500 degrees Fahrenheit). The use of insulating fire bricks in the kiln can help prevent heat loss, improve energy efficiency, and reduce fuel consumption. These bricks create a barrier between the hot gases inside the kiln and the outer environment, reducing the amount of heat that escapes. Moreover, insulating fire bricks have excellent resistance to thermal shocks, allowing them to withstand the extreme temperature fluctuations that occur in cement kilns. This durability ensures long-lasting insulation, reducing the need for frequent maintenance and replacement. However, it is important to note that the specific type and composition of insulating fire bricks required for cement kiln insulation may vary depending on the kiln's design, operating conditions, and other factors. It is advisable to consult with experts or manufacturers who specialize in refractory materials to ensure the correct selection and installation of insulating fire bricks for cement kiln insulation.

- Q: Are insulating fire bricks resistant to metal penetration?

- Insulating fire bricks possess a general resistance to the penetration of metal. These bricks are composed of refractory materials with high melting points and are engineered to endure elevated temperatures. Their application is often found in environments subject to extreme heat, such as furnaces and kilns. The thermal conductivity of insulating fire bricks is low, denoting their effectiveness in impeding heat transfer. This characteristic aids in maintaining a cool outer surface for the bricks, even when the interior is subjected to intense heat. Consequently, such bricks exhibit the ability to withstand the infiltration of molten metal. Nonetheless, it is worth noting that the resistance of insulating fire bricks to metal penetration varies according to the individual composition and quality of the bricks. Inferior-grade bricks may not offer the same level of resistance as their higher-quality counterparts. Furthermore, the duration and intensity of exposure to heat can also influence the bricks' resistance. In conclusion, while insulating fire bricks generally exhibit resistance to metal penetration, it is vital to consider the specific attributes and quality of the bricks employed, as well as the conditions under which they are exposed to heat.

- Q: What's the price of lightweight refractory bricks?

- Insulation bricks according to size, material, performance of different prices are not the same, the same products in different regions also vary slightly

- Q: Can insulating fire bricks be used in residential fireplaces?

- Yes, insulating fire bricks can be used in residential fireplaces. These bricks are designed to withstand high temperatures, making them an ideal choice for lining the interior of a fireplace. They help to retain heat and improve the overall efficiency of the fireplace. Additionally, insulating fire bricks are lightweight and easy to install, making them a practical option for residential use.

- Q: Are insulating fire bricks resistant to corrosion?

- Yes, insulating fire bricks are resistant to corrosion.

- Q: Do insulating fire bricks have good mechanical strength?

- Compared to regular fire bricks, insulating fire bricks typically possess moderate mechanical strength. Although their primary function is to offer exceptional thermal insulation, they can still endure a certain degree of mechanical strain. Nevertheless, it is crucial to acknowledge that their mechanical strength might not be as robust as other fire brick variants explicitly engineered to withstand heavier loads and abrasion. Consequently, if the objective is to attain both high insulation and superior mechanical strength, contemplating the utilization of a blend of insulating fire bricks and regular fire bricks could be necessary.

- Q: Are insulating fire bricks resistant to alkali vapor attack?

- Yes, insulating fire bricks are generally resistant to alkali vapor attack. These bricks are made using high-quality refractory materials, such as fire clay or silica, which have excellent resistance to chemical attacks, including alkali vapor. They are designed to withstand high temperatures and harsh environments, making them suitable for applications where alkali vapor may be present, such as in industrial furnaces, kilns, and incinerators. However, the exact resistance may vary depending on the specific composition and manufacturing process of the insulating fire bricks. It is always recommended to consult the manufacturer's specifications or seek expert advice to ensure their compatibility with alkali vapor exposure.

- Q: Can insulating fire bricks be used in the construction of foundry molds?

- Insulating fire bricks are capable of being utilized in the construction of foundry molds. These bricks are produced using lightweight materials like clay, alumina, and silica, and are specifically designed to possess low thermal conductivity. This quality renders them ideal for various applications that necessitate resistance against high temperatures and insulation, particularly foundry molds. Foundry molds are employed to shape and retain molten metal during the casting procedure. Given that molten metal is generally poured at exceedingly high temperatures, it becomes imperative to employ materials that can endure the heat without melting or distorting. Insulating fire bricks possess a high melting point and exceptional thermal stability, making them appropriate for usage in foundry molds. Furthermore, apart from their resistance to high temperatures, insulating fire bricks also offer commendable insulation properties. This proves to be crucial in foundry molds as it assists in regulating the cooling rate of the molten metal, thereby preventing thermal shock and ensuring proper solidification. The insulation properties of insulating fire bricks also contribute to lowering energy consumption and enhancing the overall efficiency of the foundry process. All in all, insulating fire bricks are an enduring and efficient choice for the construction of foundry molds. They provide resistance against high temperatures, excellent thermal stability, and reliable insulation properties, thus establishing themselves as a dependable option for employment in the demanding conditions of foundry operations.

- Q: Can insulating fire bricks be used in space heating applications?

- Yes, insulating fire bricks can be used in space heating applications. Insulating fire bricks are designed to have low thermal conductivity, which means they can effectively retain and distribute heat in a space heating system. These bricks are made from lightweight refractory materials that have excellent insulation properties, allowing them to trap heat and prevent its loss to the surroundings. This makes them ideal for use in space heating applications where energy efficiency is important. Additionally, insulating fire bricks can withstand high temperatures and are resistant to thermal shock, making them suitable for use in heating systems that operate at elevated temperatures. Overall, insulating fire bricks are a reliable and efficient option for space heating applications.

- Q: Can insulating fire bricks be used in the construction of industrial furnaces?

- Yes, insulating fire bricks can be used in the construction of industrial furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and thermal shocks, making them suitable for use in furnaces where temperatures can reach extremely high levels. These bricks have low thermal conductivity, which helps to minimize heat loss and improve energy efficiency in the furnace. Additionally, insulating fire bricks are lightweight and easy to handle, making them convenient for construction purposes. Overall, their excellent insulation and heat-resistant properties make insulating fire bricks an ideal choice for industrial furnace construction.

Send your message to us

Insulating Fire Brick - Refractory Mulite Insulating Fire Brick GJM25

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords