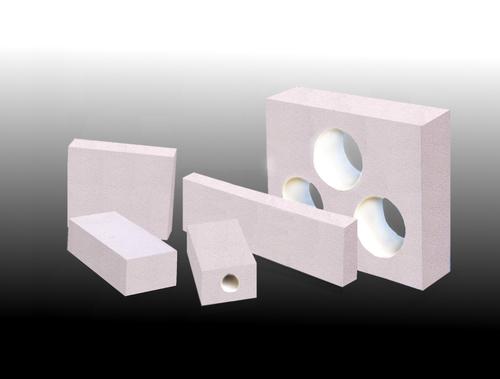

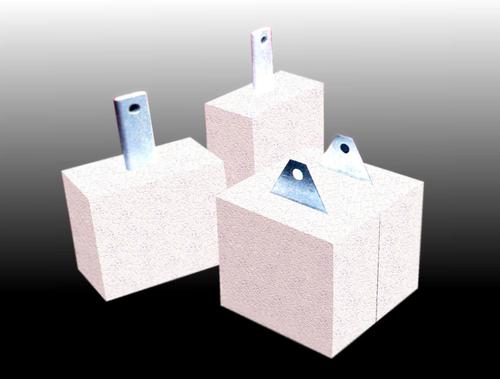

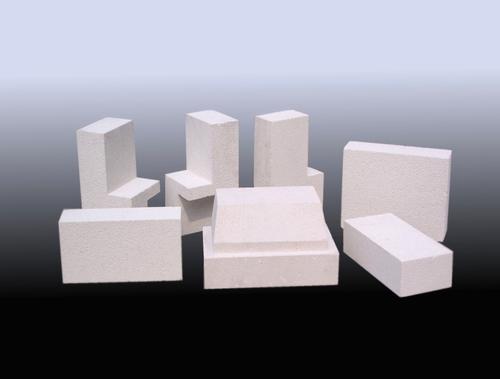

Insulating Fire Brick - Refractory Insulating Fire Brick Code GJM23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Technical Data

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Can insulating fire bricks be used in refractory linings for boilers?

- Yes, insulating fire bricks can be used in refractory linings for boilers. These bricks have high insulating properties and can withstand high temperatures, making them suitable for use in boiler linings to reduce heat loss and improve energy efficiency.

- Q: Are insulating fire bricks suitable for use in autoclaves?

- Insulating fire bricks are not typically suitable for use in autoclaves. Autoclaves are high-temperature and high-pressure environments used for various applications such as sterilization, curing, and material testing. The insulating fire bricks are designed to have low thermal conductivity and are primarily used to provide insulation and reduce heat loss in applications where high temperatures are involved. In autoclaves, the environment requires materials that can withstand both high temperatures and high pressures. Insulating fire bricks are not designed to handle the high pressures typically found in autoclaves, and using them in such environments may result in structural failure or damage. For autoclave applications, it is recommended to use refractory bricks or materials specifically designed for high-temperature and high-pressure conditions. These materials are engineered to withstand the extreme conditions inside an autoclave, ensuring safety and longevity of the equipment.

- Q: Can insulating fire bricks be used in metal smelting furnaces?

- Yes, insulating fire bricks can be used in metal smelting furnaces. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in furnaces where metal smelting occurs. They help maintain consistent heat levels and reduce heat loss, allowing for efficient and effective metal smelting processes.

- Q: Can insulating fire bricks be used in chemical processing plants?

- Yes, insulating fire bricks can be used in chemical processing plants. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for various industrial applications, including chemical processing. They can be used to line furnaces, kilns, reactors, and other equipment where temperature control and insulation are essential for efficient and safe operations in the chemical industry.

- Q: Can insulating fire bricks be used in oil refineries?

- Yes, insulating fire bricks can be used in oil refineries. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for various industrial applications, including oil refineries. They help to reduce heat loss, improve energy efficiency, and protect the surrounding equipment and structures from extreme heat.

- Q: Can insulating fire bricks be used for insulation in steam pipes?

- Yes, insulating fire bricks can be used for insulation in steam pipes. They are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for this application.

- Q: Can insulating fire bricks be used in applications involving molten metal?

- Yes, insulating fire bricks can be used in applications involving molten metal. Insulating fire bricks have high heat resistance and low thermal conductivity, making them suitable for withstanding the extreme temperatures generated by molten metal. They can be used in applications such as furnaces, kilns, and foundries, providing insulation and protection against heat transfer.

- Q: What is the typical open porosity of an insulating fire brick?

- The typical open porosity of an insulating fire brick can vary depending on the specific type and manufacturer. However, on average, insulating fire bricks have an open porosity ranging from 45% to 70%. This means that approximately 45% to 70% of the volume of the brick is made up of interconnected voids or pores. The open porosity is an important characteristic of insulating fire bricks as it directly affects their thermal insulation properties. The higher the open porosity, the better the insulating capabilities of the brick, as the voids act as barriers to heat transfer. Insulating fire bricks with lower open porosity are often denser and more durable, but they may have reduced thermal insulation properties.

- Q: Are insulating fire bricks resistant to chemicals?

- Yes, insulating fire bricks are generally resistant to chemicals. They are designed to withstand high temperatures and have low thermal conductivity, making them an ideal choice for applications involving chemicals. These bricks are typically made from ceramic materials, such as alumina, which has excellent chemical resistance properties. However, it is important to note that the degree of chemical resistance can vary depending on the specific type of insulating fire brick and the chemicals involved. Some chemicals, especially highly corrosive or reactive ones, may still cause damage or degradation to the bricks over time. Therefore, it is advisable to consult the manufacturer or supplier for detailed information on the chemical resistance capabilities of specific insulating fire bricks.

- Q: Are insulating fire bricks resistant to sulfates?

- Yes, insulating fire bricks are generally resistant to sulfates. They are designed to withstand high temperatures and are made from materials such as alumina and silica, which are known to have good chemical resistance. However, it is recommended to check the specific product specifications or consult with the manufacturer to ensure their suitability for sulfates in your specific application.

Send your message to us

Insulating Fire Brick - Refractory Insulating Fire Brick Code GJM23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords