Insulating Fire Brick GJM Series - Refractory and Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 17 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

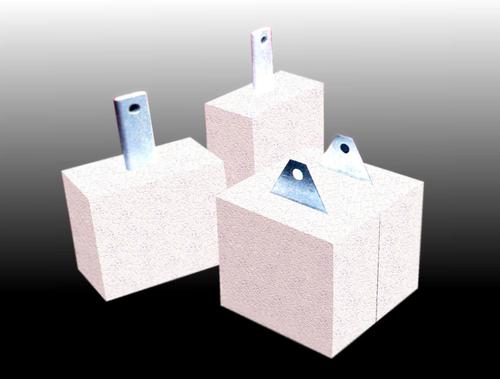

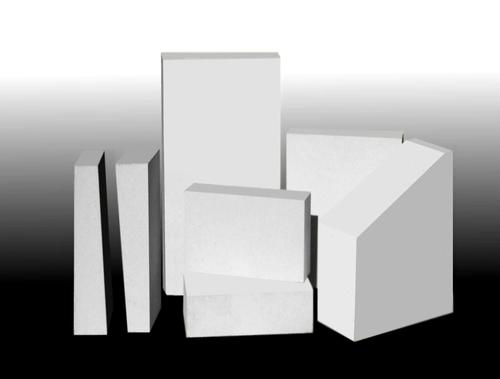

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Can insulating fire bricks be used for high-temperature applications?

- Insulating fire bricks are widely employed for applications involving high temperatures. These bricks have been crafted to offer exceptional thermal insulation and endure extreme temperatures. Depending on the specific type and composition of the brick, they can typically withstand temperatures of up to 2600°F (1427°C) or even higher. Kilns, furnaces, and industrial settings that necessitate high temperatures commonly utilize insulating fire bricks. These bricks are renowned for their minimal thermal conductivity, which aids in reducing heat loss and enhancing energy efficiency. Moreover, these bricks possess the advantages of being lightweight, long-lasting, and resistant to thermal shock, rendering them ideal for environments with elevated temperatures.

- Q: Can insulating fire bricks be used in high-temperature insulation boards?

- Indeed, high-temperature insulation boards can utilize insulating fire bricks for their thermal insulation needs. These bricks are specifically engineered to endure extreme temperatures while offering exceptional thermal insulation. They find widespread use in various applications demanding insulation under elevated temperatures, including kilns, furnaces, and fireplaces. By incorporating insulating fire bricks into high-temperature insulation boards, one can effectively reduce heat loss and uphold a consistent temperature. Nevertheless, it is crucial to assess the particular prerequisites of the application and verify the compatibility of the insulating fire bricks with the insulation board material and installation technique.

- Q: Can insulating fire bricks be used for soundproofing?

- Insulating fire bricks are primarily used for thermal insulation in high-temperature applications, such as kilns and furnaces. While they may offer some level of sound absorption due to their porous nature, they are not specifically designed or recommended for soundproofing purposes. For effective soundproofing, specialized materials with higher sound absorption coefficients should be used.

- Q: Are insulating fire bricks suitable for use in coke ovens?

- Yes, insulating fire bricks are suitable for use in coke ovens. These bricks are designed to withstand high temperatures and provide excellent insulation properties, making them ideal for use in coke ovens where extreme heat is generated during the coking process. They help to maintain the desired temperature inside the oven and prevent heat loss, resulting in improved energy efficiency and reduced fuel consumption. Additionally, insulating fire bricks have good resistance to chemical reactions and thermal shock, which further enhances their suitability for use in coke ovens.

- Q: Are insulating fire bricks suitable for use in residential fireplaces?

- Yes, insulating fire bricks are suitable for use in residential fireplaces. They are designed to withstand high temperatures and provide insulation, making them an ideal choice for ensuring the safety and efficiency of a residential fireplace.

- Q: Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them excellent for applications where heat insulation is required. In lime production, high temperatures are required for the calcination process. Using insulating fire bricks in the construction of lime production linings helps to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and easy to handle, which makes them suitable for lining various parts of lime kilns and other equipment used in the lime production process. Overall, using insulating fire bricks in lime production linings can help to optimize the production process and improve the overall performance of lime production facilities.

- Q: Can insulating fire bricks be used in chimney liners?

- Yes, insulating fire bricks can be used in chimney liners. They are designed to withstand high temperatures and provide insulation, making them suitable for use in chimneys to improve efficiency and prevent heat loss.

- Q: Are insulating fire bricks suitable for insulation in cryogenic applications?

- Insulating fire bricks are indeed appropriate for insulation in cryogenic applications. These bricks are crafted from lightweight refractory materials that possess exceptional thermal insulation qualities. With their low thermal conductivity, high melting points, and ability to withstand extremely frigid temperatures, they are perfectly suited for cryogenic applications. Cryogenic applications entail the handling and storage of materials at exceedingly low temperatures, typically below -150 degrees Celsius (-238 degrees Fahrenheit). Insulating fire bricks are specifically designed to provide efficient insulation in such extreme conditions, effectively preventing heat transfer and maintaining the desired low temperature. Moreover, insulating fire bricks exhibit chemical stability and possess excellent resistance to thermal shock. This means they can endure rapid temperature fluctuations without cracking or deteriorating, which is particularly crucial in cryogenic applications where such variations are commonplace. In addition to their exceptional thermal insulation qualities, insulating fire bricks are lightweight and easy to handle, making them convenient for installation in cryogenic systems. All in all, insulating fire bricks are a suitable choice for insulation in cryogenic applications due to their thermal insulation properties, resistance to high temperatures, chemical stability, and ability to withstand thermal shock.

- Q: Do insulating fire bricks require a refractory mortar for installation?

- For proper installation, insulating fire bricks typically require the use of refractory mortar. These bricks are lightweight and have excellent insulating properties, making them well-suited for applications that prioritize thermal efficiency. However, their lightweight nature also means they are more fragile and susceptible to cracking or breaking when subjected to stress. To establish a robust and durable bond between the bricks, it is essential to use a refractory mortar specifically designed for high-temperature applications. These mortars are formulated to withstand high temperatures and possess superior adhesion and thermal expansion properties. By filling in the gaps between the bricks and providing additional support, this mortar helps create a solid and secure structure. Failure to use refractory mortar can lead to inadequate securing of the insulating fire bricks, potentially causing them to shift or separate over time and compromising the integrity of the installation. Additionally, the absence of refractory mortar may result in reduced thermal efficiency due to increased heat loss through gaps and spaces between the bricks. Therefore, it is highly advisable to employ refractory mortar when installing insulating fire bricks to ensure the construction remains strong and long-lasting.

- Q: Can insulating fire bricks be used as a lining for chimneys?

- Yes, insulating fire bricks can be used as a lining for chimneys. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for lining chimneys and protecting them from heat damage.

Send your message to us

Insulating Fire Brick GJM Series - Refractory and Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 17 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords