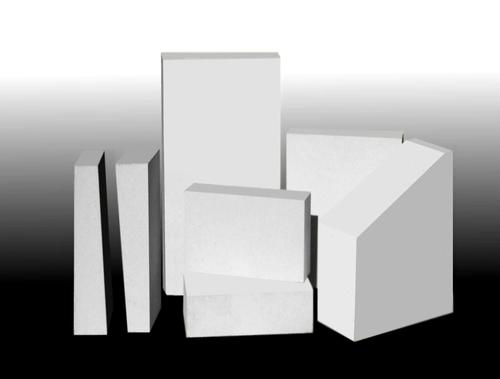

Advanced Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

- Q: Advantages and disadvantages of external formwork and self thermal insulation block

- Exterior wall insulation form, single material thermal insulation exterior wall: aerated concrete, sintered insulation brick compound thermal insulation exterior wall:According to the different settings of thermal insulation materials, it can be divided into internal insulation, external insulation and sandwich insulation exterior wall. Thermal insulation decorative integrated board: Other: thermal insulation block, etc..

- Q: Are insulating fire bricks resistant to vibration or seismic activity?

- Yes, insulating fire bricks are typically resistant to vibration or seismic activity. They are designed to withstand high temperatures and provide insulation, which also makes them relatively stable and resistant to external forces such as vibrations or seismic activity.

- Q: Can insulating fire bricks be used in the construction of brick kilns?

- Yes, insulating fire bricks can be used in the construction of brick kilns. Insulating fire bricks are specifically designed to have high thermal resistance, which makes them ideal for applications where insulation is required. In brick kilns, insulating fire bricks can be used to line the walls, floor, and roof of the kiln, helping to retain heat and improve energy efficiency. These bricks are capable of withstanding high temperatures and can provide insulation against the heat generated during the firing process. Additionally, insulating fire bricks can also help reduce heat loss, resulting in faster and more efficient firing cycles. Overall, using insulating fire bricks in the construction of brick kilns can enhance their performance and contribute to more effective and sustainable kiln operation.

- Q: What is the recommended thickness of insulating fire bricks for optimal insulation?

- The recommended thickness of insulating fire bricks for optimal insulation can vary depending on the specific application and desired level of thermal protection. However, in general, insulating fire bricks with a thickness ranging from 2.5 to 4 inches (6.35 to 10.16 cm) are commonly recommended for achieving efficient insulation. Insulating fire bricks are designed to have low thermal conductivity, which means they are able to effectively minimize heat transfer. The thicker the bricks, the higher the insulating properties as they provide a greater barrier against thermal energy loss or gain. This is particularly important in applications where maintaining a stable temperature is crucial, such as in industrial furnaces, kilns, or high-temperature appliances. It is important to consider the specific requirements of the insulation project and consult with experts or manufacturers to determine the most suitable thickness for the insulating fire bricks. Factors such as the maximum temperature, duration of exposure, and desired energy efficiency should be taken into account to ensure optimal insulation performance.

- Q: Can insulating fire bricks be used in refractory lining applications?

- Yes, insulating fire bricks can be used in refractory lining applications. Insulating fire bricks are made from lightweight materials that have high insulating properties, such as clay or silica. These bricks are designed to provide excellent thermal insulation, reducing heat loss and improving energy efficiency in high-temperature applications. In refractory lining applications, insulating fire bricks are commonly used to line the walls, floors, and roofs of furnaces, boilers, kilns, and other industrial equipment. They are effective in preventing heat transfer to the surrounding environment and maintaining the desired temperature inside the equipment. Insulating fire bricks are also resistant to thermal shock, meaning they can withstand rapid changes in temperature without cracking or failing. This makes them suitable for applications where the equipment goes through frequent heating and cooling cycles. Furthermore, insulating fire bricks have low thermal conductivity, which means they can effectively limit heat transfer between different areas of the refractory lining. This helps to prevent hot spots and temperature imbalances, ensuring uniform heat distribution throughout the equipment. Overall, insulating fire bricks are a versatile and effective choice for refractory lining applications, providing excellent thermal insulation, resistance to thermal shock, and uniform heat distribution.

- Q: Can insulating fire bricks be used in the construction of BBQ pits?

- Yes, insulating fire bricks can be used in the construction of BBQ pits. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for creating a heat-resistant structure. They help to retain and distribute heat evenly, which is crucial for achieving optimal cooking conditions in a BBQ pit.

- Q: Can insulating fire bricks be used for insulation in heat recovery systems?

- Yes, insulating fire bricks can be used for insulation in heat recovery systems. Insulating fire bricks are specifically designed to withstand high temperatures and provide effective thermal insulation. They have low thermal conductivity, which means they can minimize heat loss and maximize heat recovery in a system. These bricks are often used in various industrial applications such as kilns, furnaces, and ovens, where temperature control and energy efficiency are important. Therefore, they can be a suitable choice for insulating heat recovery systems, helping to optimize the recovery and utilization of waste heat.

- Q: Can insulating fire bricks be used for insulation in refractory lining repair?

- Indeed, insulation in refractory lining repair can be achieved by utilizing insulating fire bricks. Crafted from lightweight materials, these bricks boast exceptional thermal insulation properties, rendering them perfectly suitable for employment in high-temperature settings like furnaces, kilns, and other refractory lining structures. Their low thermal conductivity and impressive resistance to thermal shock enable them to effectively insulate and safeguard the refractory lining against heat, thereby averting heat loss and diminishing energy consumption. Additionally, the installation and replacement of insulating fire bricks are effortless, solidifying their position as a cost-efficient alternative for refractory lining repair.

- Q: Are insulating fire bricks suitable for use in the construction of drying ovens?

- Yes, insulating fire bricks are suitable for use in the construction of drying ovens. They have excellent thermal insulation properties, which helps to retain heat and prevent heat loss during the drying process. Additionally, insulating fire bricks can withstand high temperatures and have good resistance to thermal shocks, making them a reliable choice for drying oven construction.

- Q: Are insulating fire bricks resistant to water absorption?

- Insulating fire bricks possess resistance against water absorption. Their design emphasizes low porosity and high density, effectively preventing water from penetrating their structure. This resistance to water absorption holds significance as water exposure can result in cracks or damage to fire bricks, thereby diminishing their insulation capabilities and lifespan. Consequently, insulating fire bricks emerge as an optimal selection for applications necessitating moisture resistance, including the construction of kilns, furnaces, or other environments characterized by high temperatures.

Send your message to us

Advanced Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords